Variable-frequency control drill machine

A technology of frequency conversion speed regulation and drilling machine, which is applied to the components of boring machine/drilling machine, drilling/drilling equipment, measuring/indicating equipment, etc., which can solve the problems of inability to achieve smooth transition, inaccurate pressure regulation, and user inconvenience. , to reduce the time for workers to adjust speed, improve work efficiency, and achieve the effect of smooth transition of speed

Inactive Publication Date: 2010-12-01

QINGDAO D& D ELECTRO MECHANICAL TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The most common speed change method for drilling machines at home and abroad is belt speed change, which can only realize point-to-point speed change, but cannot achieve smooth transition, and every time the speed change needs to be opened with a tool to adjust the belt, it is time-consuming and laborious, which is very troublesome

Some can achieve a relatively smooth mechanical speed change effect through the tension and speed regulation of two pulleys, but the requirements for the belt are high, and the mechanical pressure regulation is not accurate, the operation is inconvenient, and it cannot adapt to the flexible and changeable needs of modern society. , causing great inconvenience to users

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

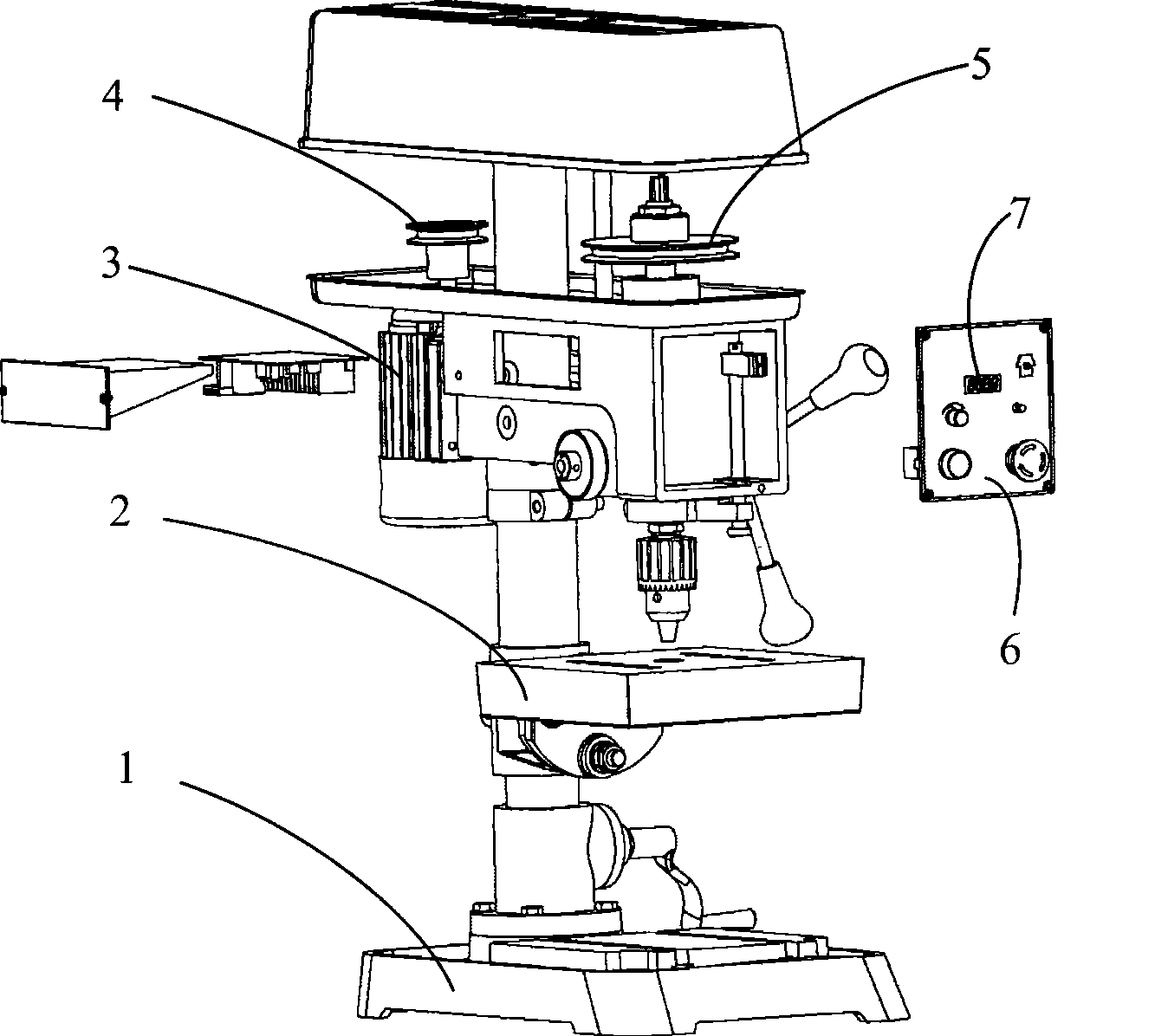

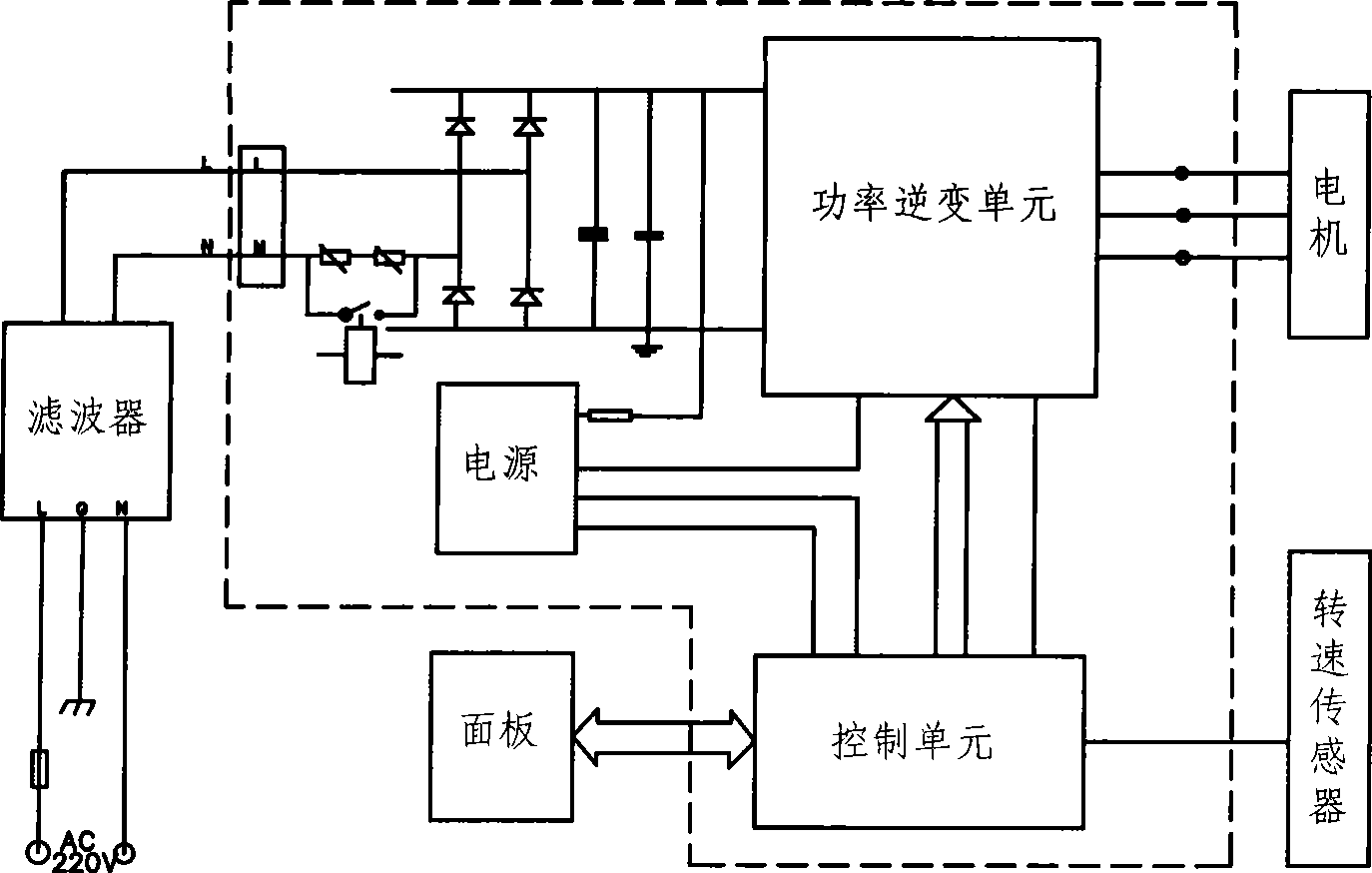

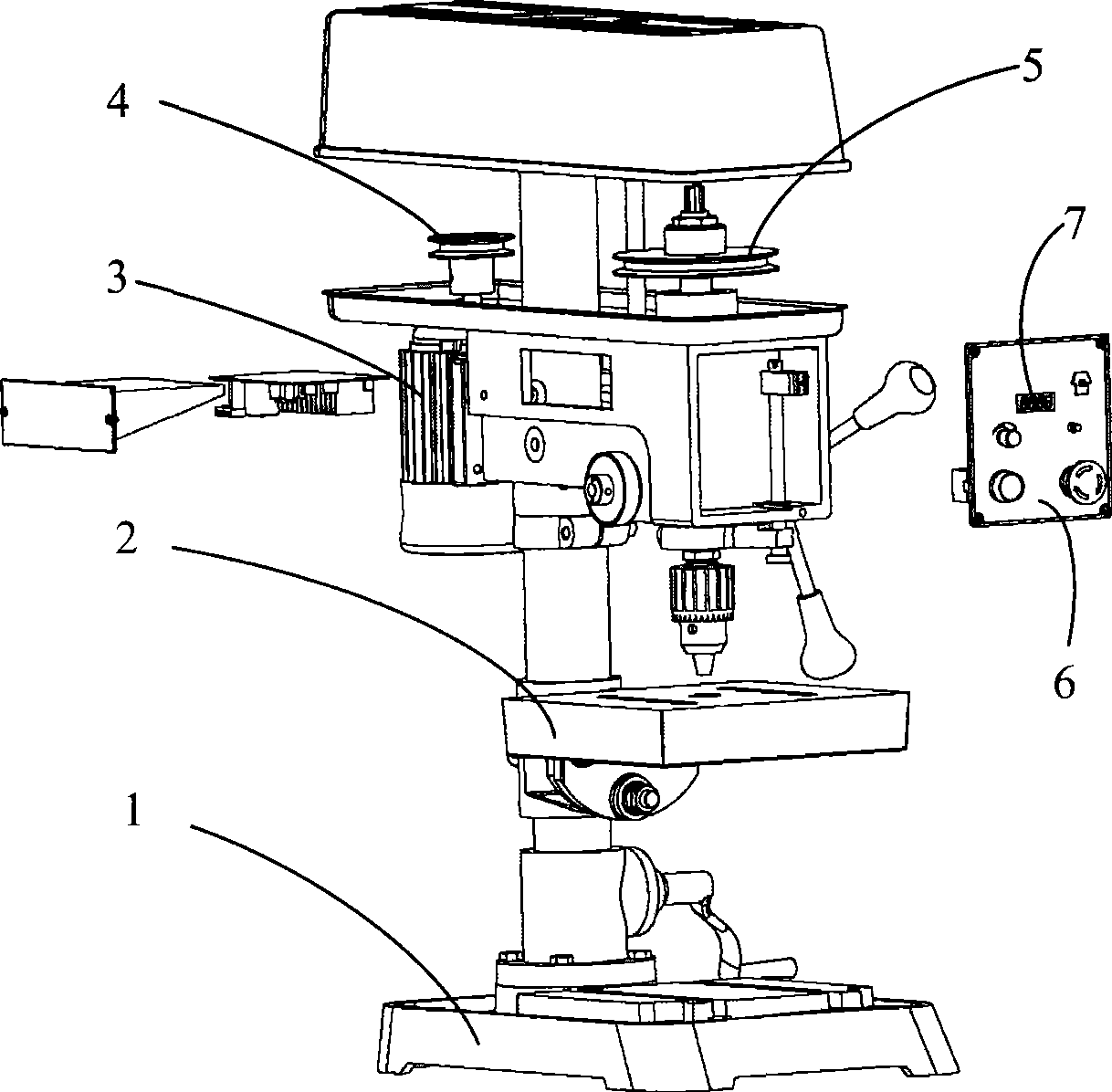

The invention relates to the drilling machine field and discloses a frequency conversion and speed regulation drilling machine which comprises a motor and a mainshaft; the drilling machine also comprises a frequency conversion and speed regulation system; the frequency conversion and speed regulation system is connected with the motor; the rotation speed of the motor is adjusted by adjusting the frequency of AC which is used for supplying the power for the motor; the drilling machine can precisely adjust the rotation speed of the motor only by rotating a knob when adopting the frequency conversion and speed regulation system; furthermore, the rotation speed is smoothly transitional, the operation is extremely simple and convenient, the time for speed regulation by workers is greatly reduced, and the working efficiency is improved further.

Description

A frequency conversion speed regulation drilling machine technical field The invention relates to the field of drilling machines, in particular to a variable frequency speed regulating drilling machine. Background technique Drilling machines are widely used in people's lives, especially in recent years with the development of industrial modernization and the improvement of people's living standards, factories, enterprises and even ordinary families will use them. The drilling machine has also developed from the initial simple function to the current complex operation requirements suitable for people's various processing requirements. But as the core of the drilling machine, the transmission transmission system is still a belt transmission, or a slightly advanced mechanical transmission. These variable speed systems have many disadvantages, resulting in complicated operation and reduced efficiency. It is increasingly unable to adapt to the faster and faster pace of life o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23B47/06B23Q17/10H02P27/06

CPCY02P70/10

Inventor 张永升高振昆姜兆泳

Owner QINGDAO D& D ELECTRO MECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com