Method for manufacturing a three dimensional frame structure for use as a core structure in a sandwich construction and frame structure manufactured thereby

A frame structure, three-dimensional technology, applied in the field of three-dimensional frame structure of core structure, can solve problems such as inflexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

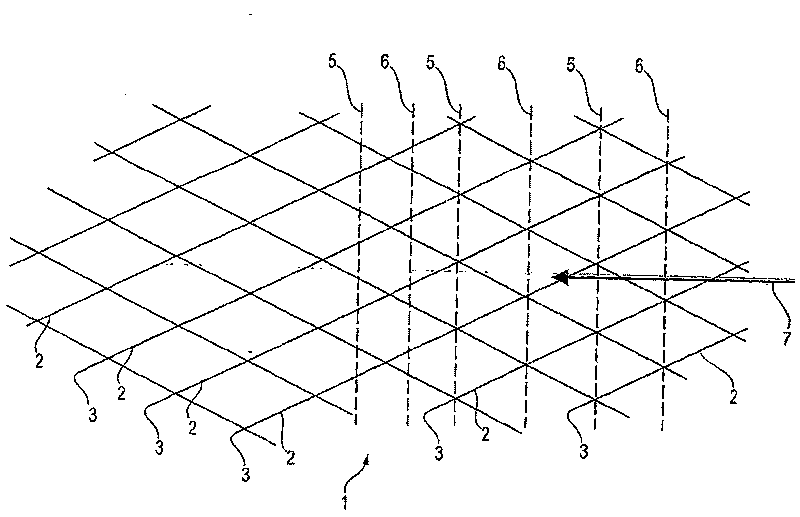

[0037] figure 1 A two-dimensional grid structure 1 is shown, which in the exemplary embodiment shown in the illustration is made from two sets of linear semi-finished products 2, wherein first the first set 2 is arranged such that the semi-finished products are placed in the first The layers extend parallel and are spaced apart from each other. Next a second group 3 of bar-shaped linear semi-finished products 3 is arranged on the first layer such that the individual bar-shaped linear semi-finished products 3 of the second group are parallel to each other and spaced from each other in a second layer above the first layer 2 Open way to extend. Due to this arrangement of the strip-shaped linear semi-finished products of the first group 2 and the second group 3 , a two-dimensional grid structure 1 is produced, wherein the individual strip-shaped linear semi-finished products in the two layers intersect at defined intersection points 4 .

[0038] Linear semi-finished products may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com