Argentine-loaded hydroxylapatite and preparation method thereof

A technology of silver-loaded hydroxyapatite and hydroxyapatite, which is applied in botany equipment and methods, chemicals for biological control, biocides, etc., can solve the problems of low binding fastness of cotton fibers, and achieve improvement Combination fastness, good compatibility and wide antibacterial spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

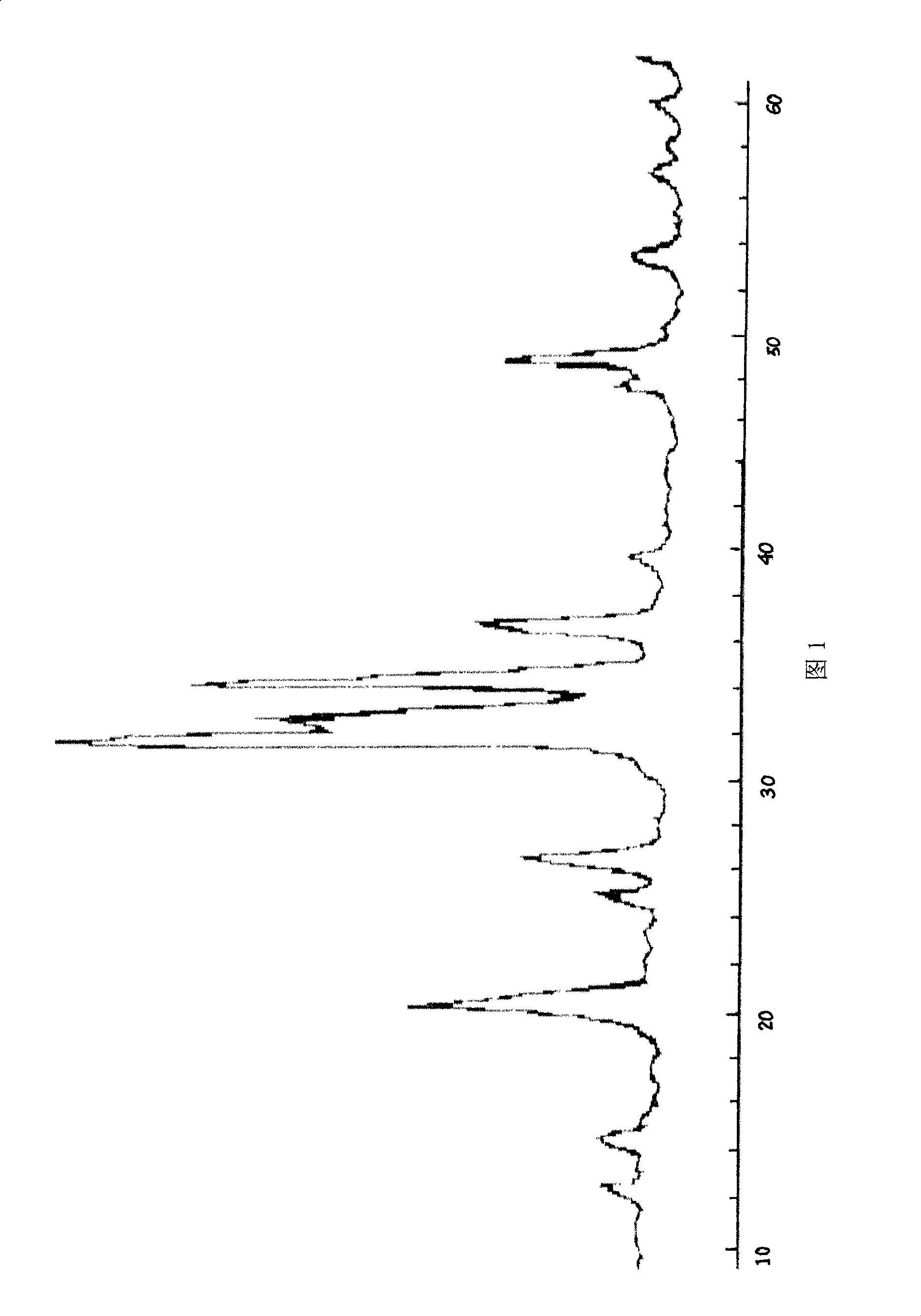

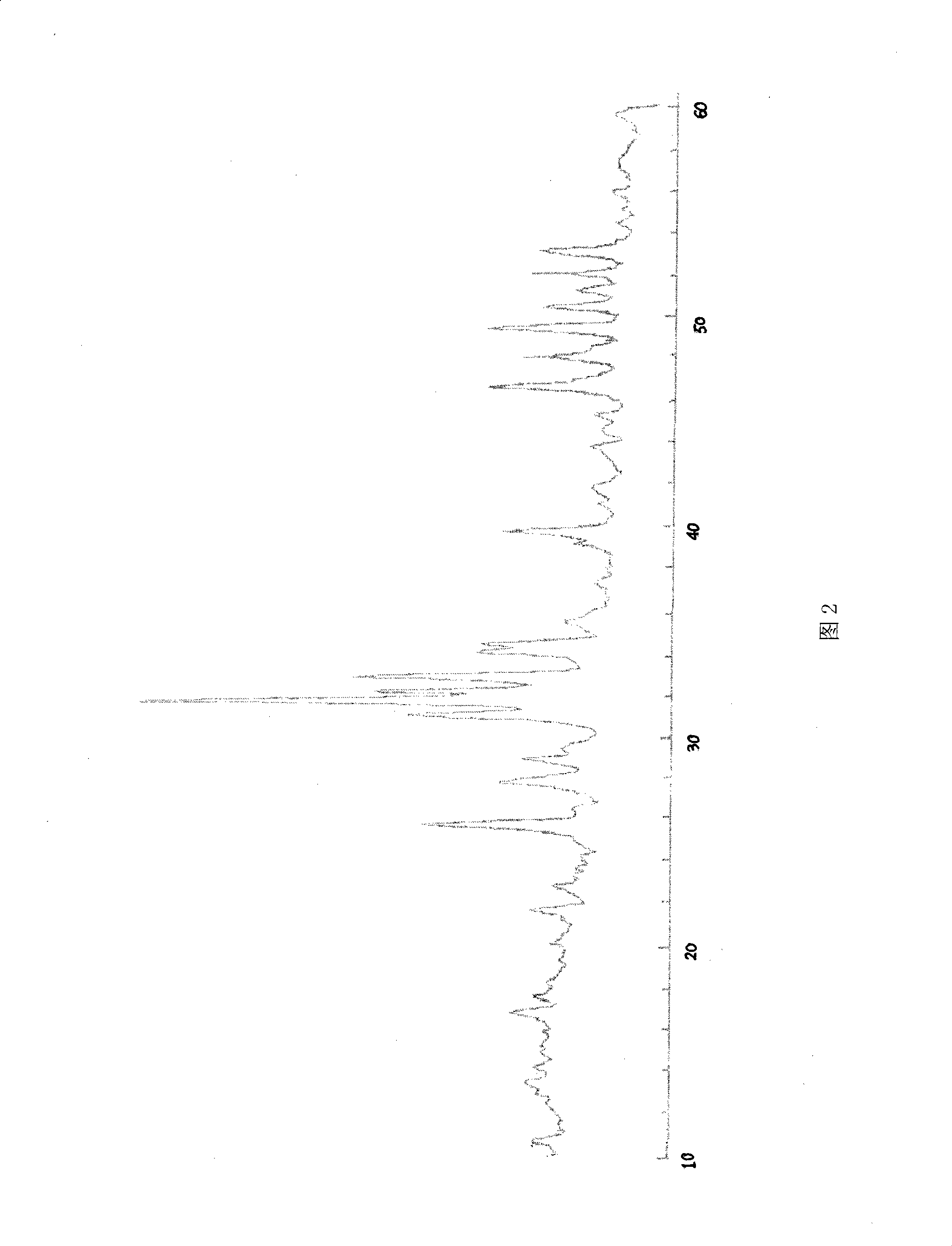

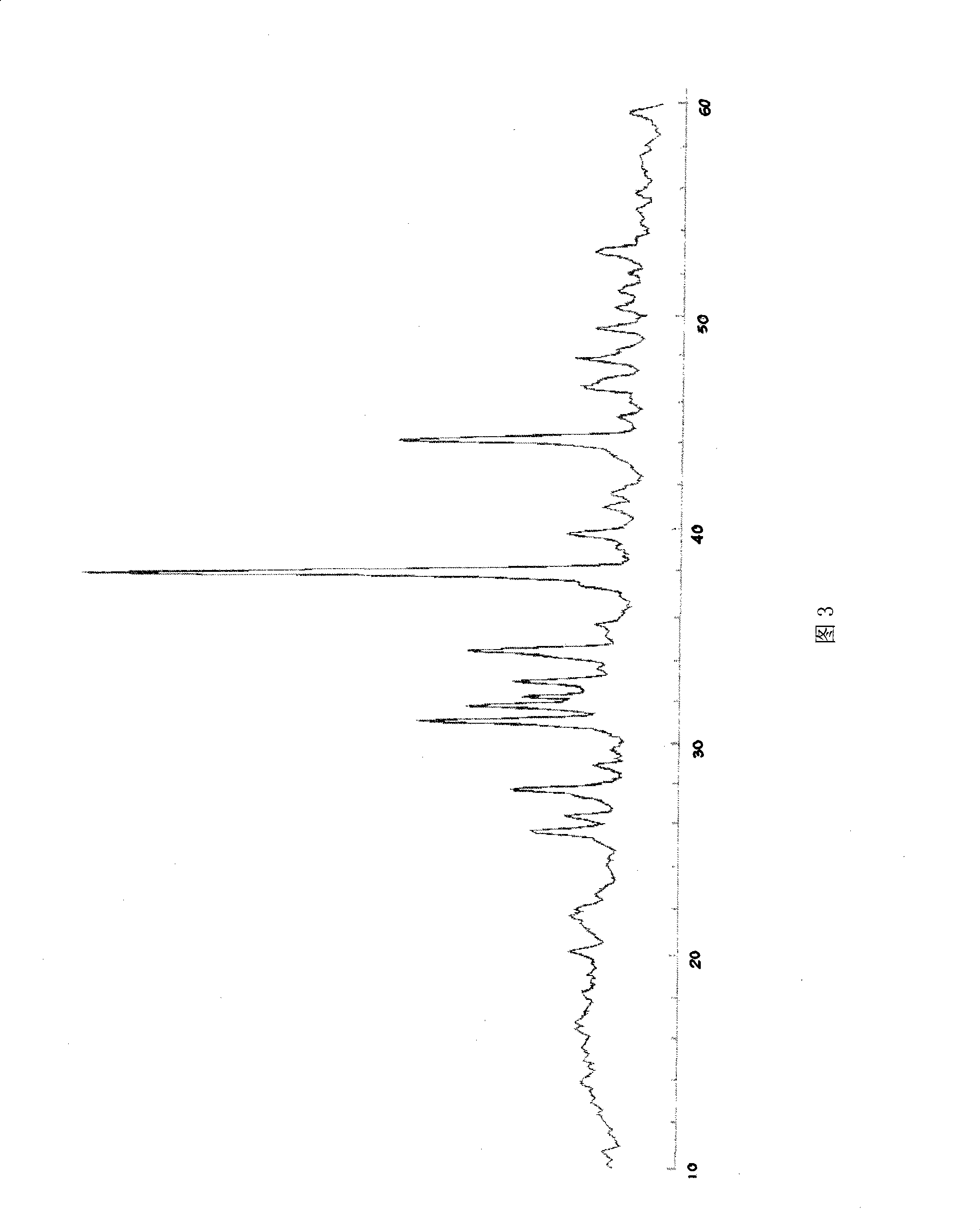

Image

Examples

Embodiment 1

[0019] A silver-loaded hydroxyapatite, in which silver is loaded on the hydroxyapatite.

Embodiment 2

[0021] A preparation method of silver-loaded hydroxyapatite, which consists of the following steps: according to the mass ratio of 1:30, AgNO with a mass concentration of 8% 3 The aqueous solution is mixed with hydroxyapatite, kept away from light, stirred at 25°C for 25 hours, ion-exchanged, filtered, dried, and calcined at 800°C for 6 hours to produce a silver-loaded hydroxyapatite.

[0022] Hydroxyapatite was prepared from Example 5.

Embodiment 3

[0024] A preparation method of silver-loaded hydroxyapatite, comprising the following steps: according to the mass ratio of 1:10, the mass concentration is 25% of AgNO 3 The aqueous solution is mixed with hydroxyapatite, stirred at 20°C for 20h in the dark, ion exchanged, filtered, dried, and calcined at 1000°C for 3h to produce a silver-loaded hydroxyapatite.

[0025] Hydroxyapatite was prepared from Example 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com