Bearing unit of drive gear wheel

A technology of driving gears and bearings, which is applied in the field of auto parts, can solve the problems affecting the bearing capacity, restricting the quality of the central transmission mechanism of the driving middle axle, and affecting the production efficiency of the chassis assembly line, so as to achieve good economic and social benefits and shorten production. Assembly time, the effect of improving production assembly efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

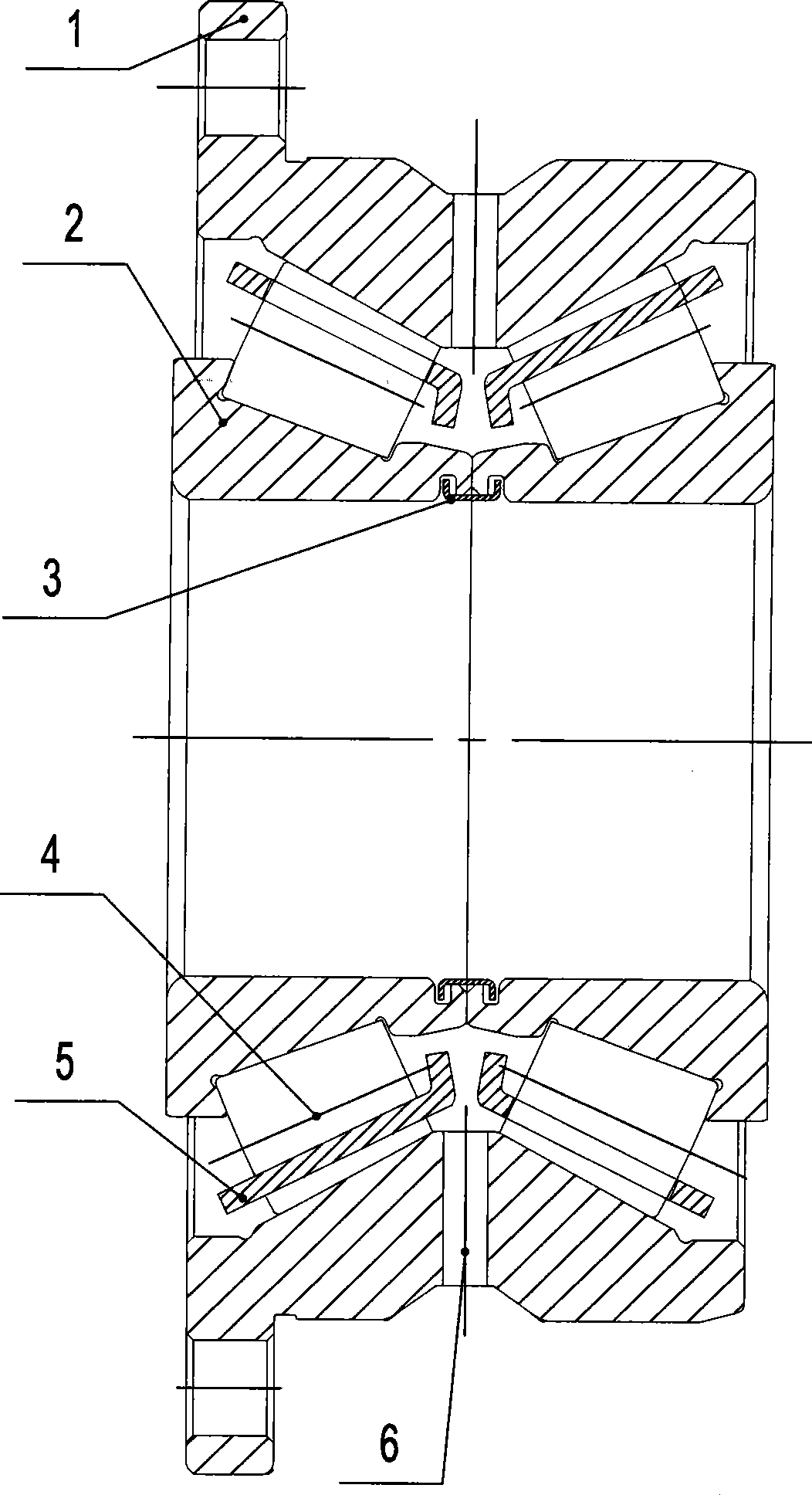

[0012] Refer to figure 1 , Driving gear bearing unit, including unit outer ring 1, two inner rings 2, two rows of tapered rollers 3, two width retainers 4 and lock catches 5. The inner side of the unit outer ring 1 is provided with two rows of parallel cones The two inner races are respectively matched with the outer races of the two inner rings 2 to form two rolling raceways; the two inner rings 2 are positioned and fixed by the lock 5; the two rows of tapered rollers 3 are respectively placed in the two pairs of cages 4 The two rows of tapered rollers 3 are respectively located in two rolling raceways and are in rolling contact with the raceways; guided by the retainer 4, the outer ring 1 of the unit is provided with a flange for directly connecting with the bridge body transition box shell. The whole unit is a fixed whole, and its pre-tightening force has been adjusted, and there is no need to set an adjustment pad for adjustment, which simplifies the structure and improves the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap