Packaging bag with tearing aid

An auxiliary mechanism and packaging bag technology, applied in the field of packaging bags, can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

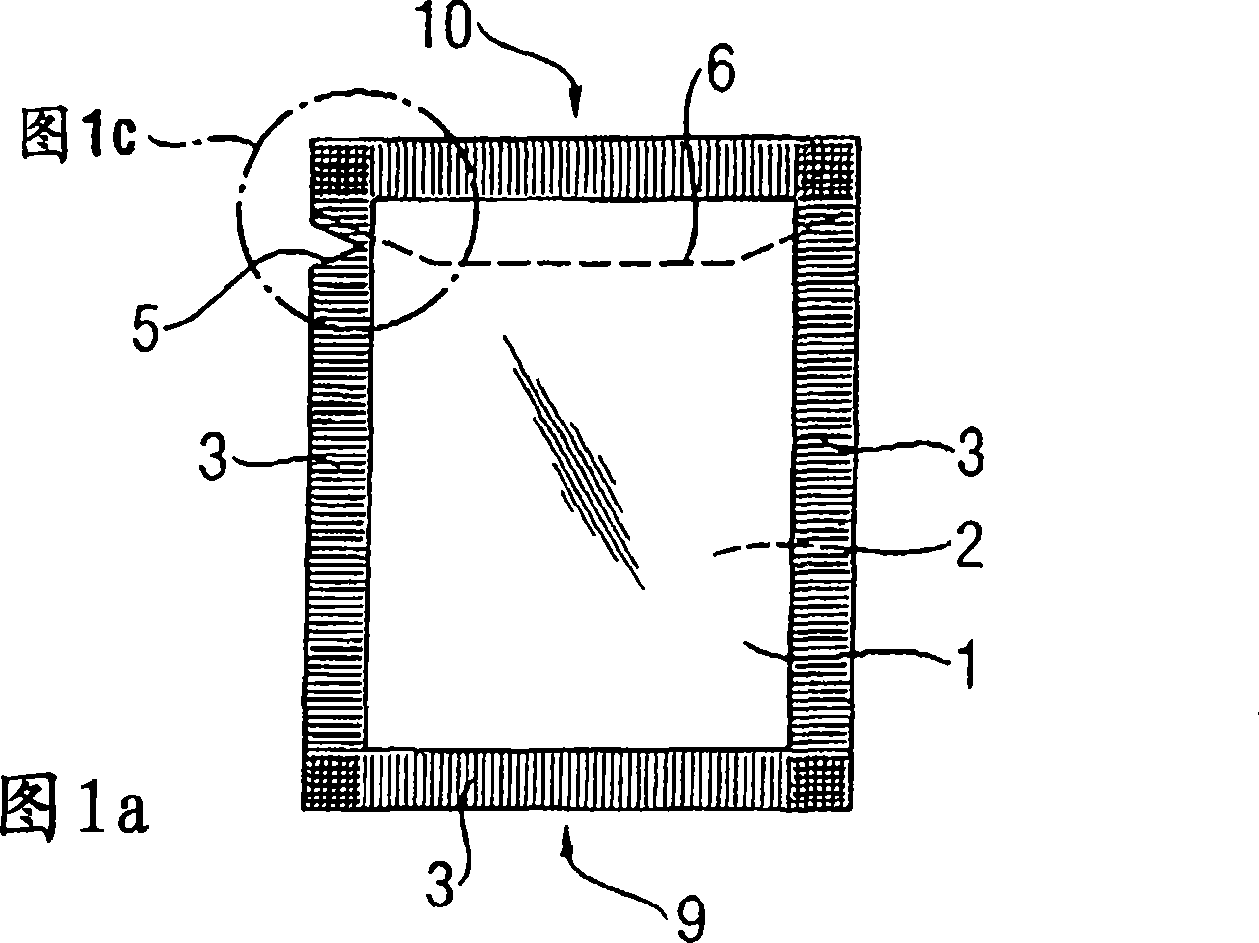

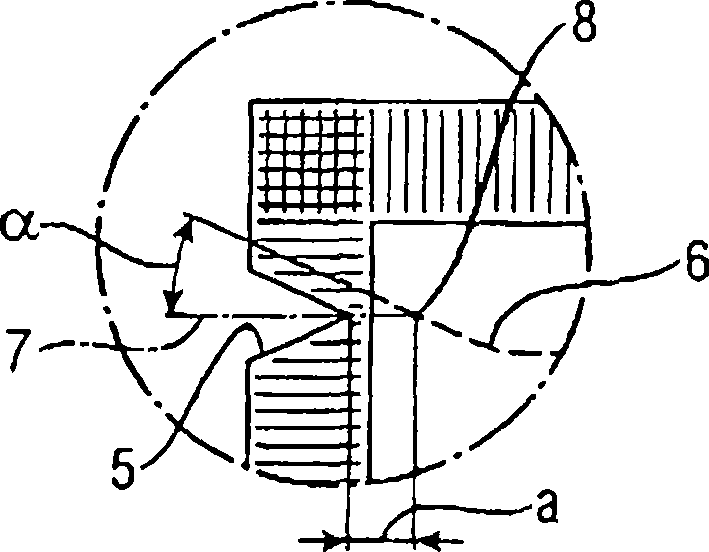

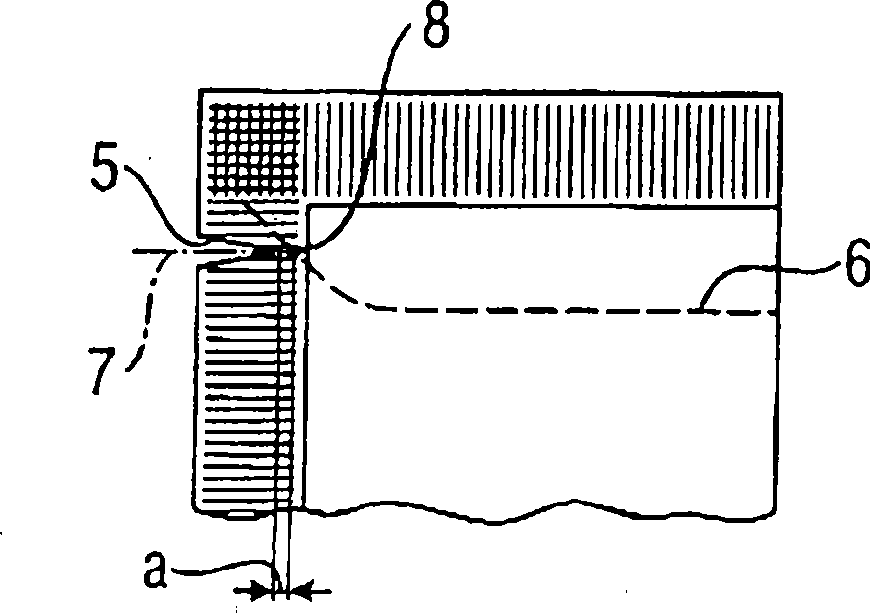

[0035] The packaging bag according to the invention, like the packaging bags known from practice, has a front side 1 and a back side 2 which are at least partially welded or glued together in the edge region. These edge regions glued or welded to one another form a joint edge 3 of a predetermined edge width.

[0036] FIG. 1 a shows a top view of a first embodiment of the packaging bag according to the invention on the front side 1 . The front side 1 and the back side 2 located behind it have a rectangular shape and are connected to each other by an annular joint edge 3 .

[0037] The blank 4 for the packaging bag shown in FIG. 1 b is preferably cut to length from a web of packaging material and has twice the width of the packaging bag. The front side 1 and the back side 2 overlap each other coveringly by folding along the middle line. The crease created by folding forms one of the two sides. It is sufficient to join both the other side and the lower edge to provide a refill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com