Method for implementing PMMA three-dimensional fine process for mobile example platform

A sample platform and sample platform technology, which are applied in chemical instruments and methods, microstructure technology, microstructure devices, etc., to achieve the effects of simple three-dimensional graphics, flexible manufacturing methods, and overcoming the complexity and high cost of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

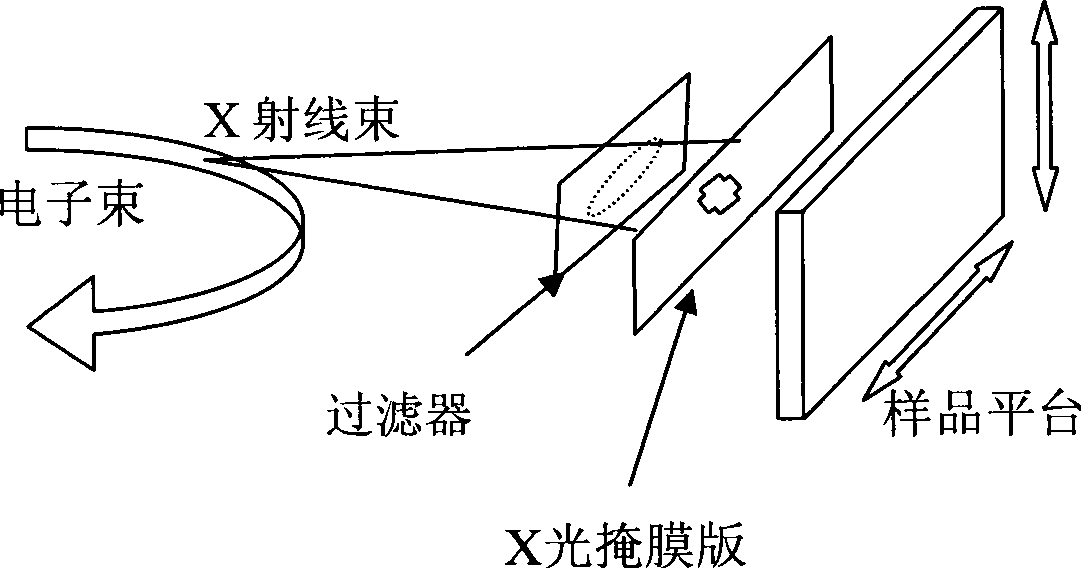

[0020] first step, such as figure 1 As shown, the high-energy cyclotron beam emits X-rays, and the total length of the X-ray beam is 1.58m. 200μm thick beryllium and 50μm thick Capeton window (5mm×30mm) are used to form a filter to obtain hard X-rays with photon energy exceeding 1.3keV. The filtered hard X-rays are irradiated onto the sample through the X-ray mask, and the sample platform fixes the sample and can realize two-dimensional translation.

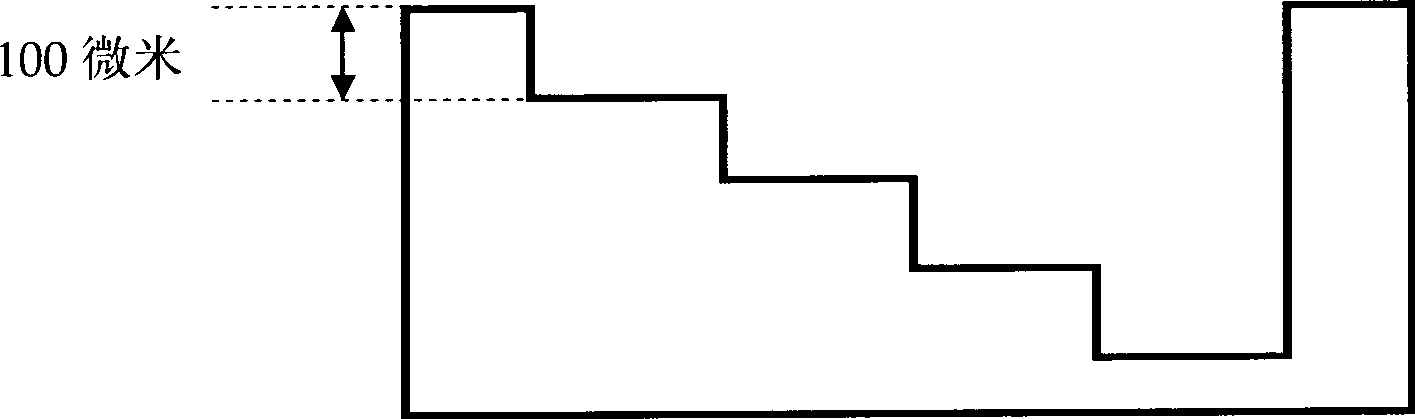

[0021] The second step is to use a reticle to precisely control the exposure time by moving the sample stage and changing the time of staying in different positions, so as to control the total amount of X-ray incident at different positions. The total amount of X-ray incidence at a certain position is proportional to the etching depth of PMMA at this position, so that a three-dimensional PMMA structure with a narrow top and a wide bottom is formed by parts with different depths.

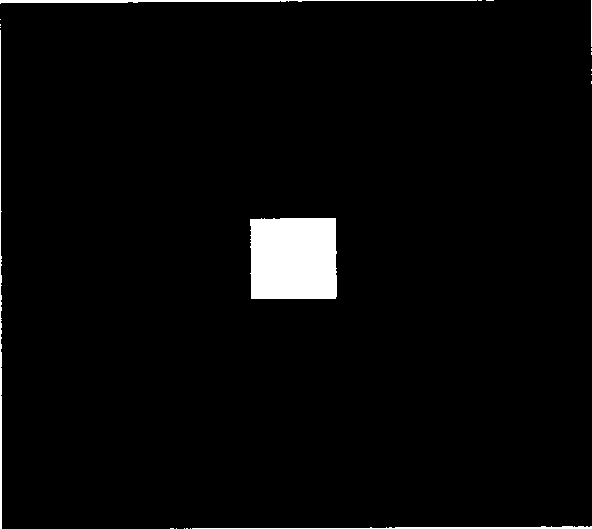

[0022] Such as figure 2 As shown, the manufac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com