Claw pole type motor and pump

一种爪极式、爪形磁极的技术,应用在爪极式电机领域,能够解决损坏铁心等问题,达到抑制损坏、节约材料成本、加宽流路的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

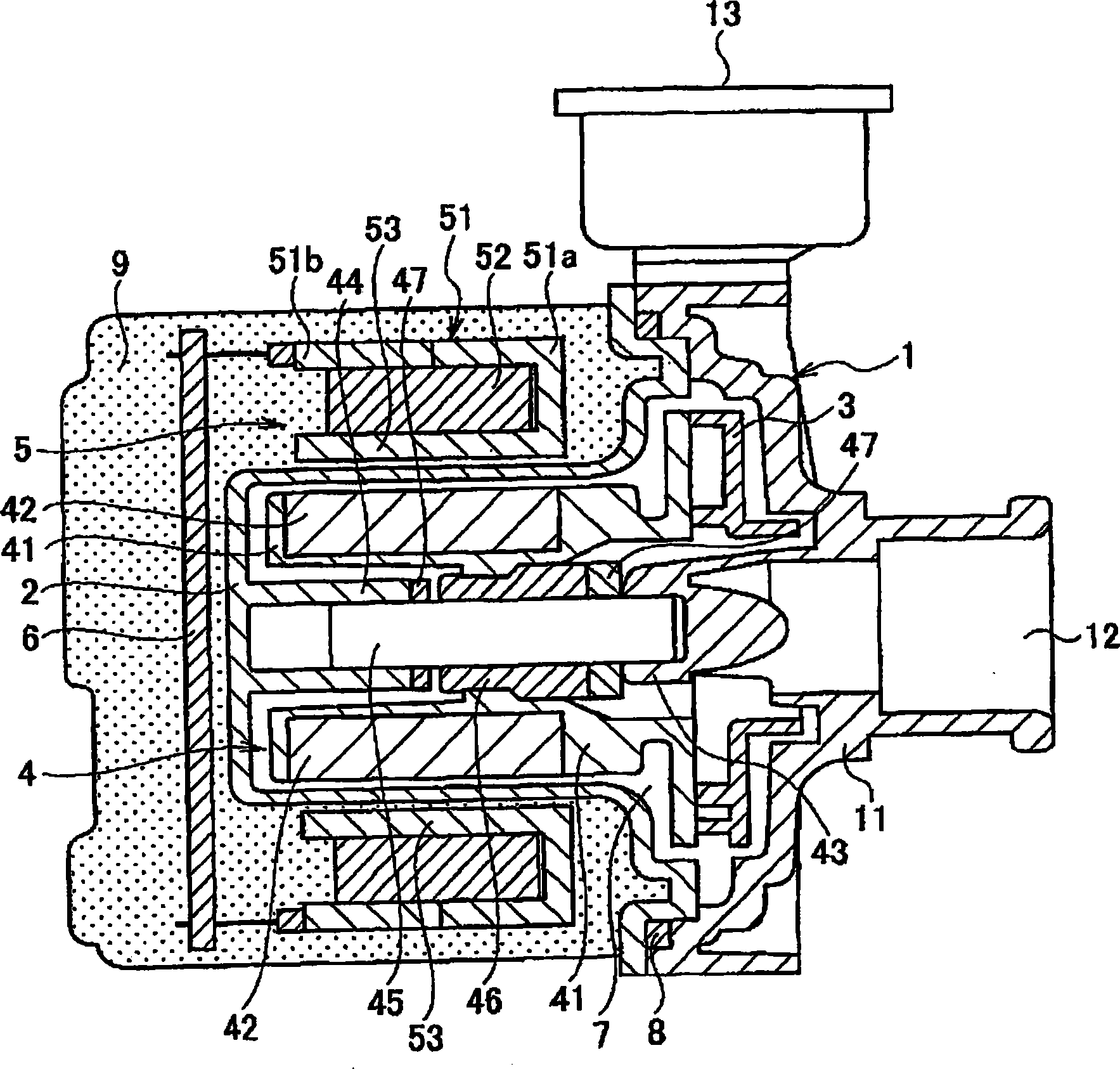

[0026] figure 1 is a sectional view of the pump according to the first embodiment of the present invention. This pump uses a claw-pole motor as its driving power source, and is mainly composed of a pump casing 1 , a partition 2 , an impeller 3 , a rotor 4 , a stator 5 , and a control circuit board 6 .

[0027] The pump housing 1 and the partition 2 are connected together to define a pump chamber 7 . A sealing element 8 is arranged in the connecting portion of the pump housing 1 and the partition 2 to ensure the liquid tightness of the pump chamber 7 . The impeller 3 and the rotor 4 are rotatably housed in the pump chamber 7 in a state of being integral with each other. The stator 5 is arranged around the rotor 4 in facing relationship with the rotor 4 with the partition 2 interposed therebetween, thereby forming a so-called inner rotor structure. The entire part of the pump except the pump housing 1 is coated with molding resin 9 . In other words, the partition 2 , the sta...

no. 2 example

[0046] Figure 6A and 6B is a schematic perspective view of a stator 5 according to a second embodiment of the present invention, which shows the same as that of the first embodiment Figure 3A and 3B Corresponding. The pump of the second embodiment differs from the pump of the first embodiment in the structure of the stator 5 . The same parts as in the first embodiment are denoted by the same reference numerals, and redundant descriptions are omitted. Those differences are highlighted below.

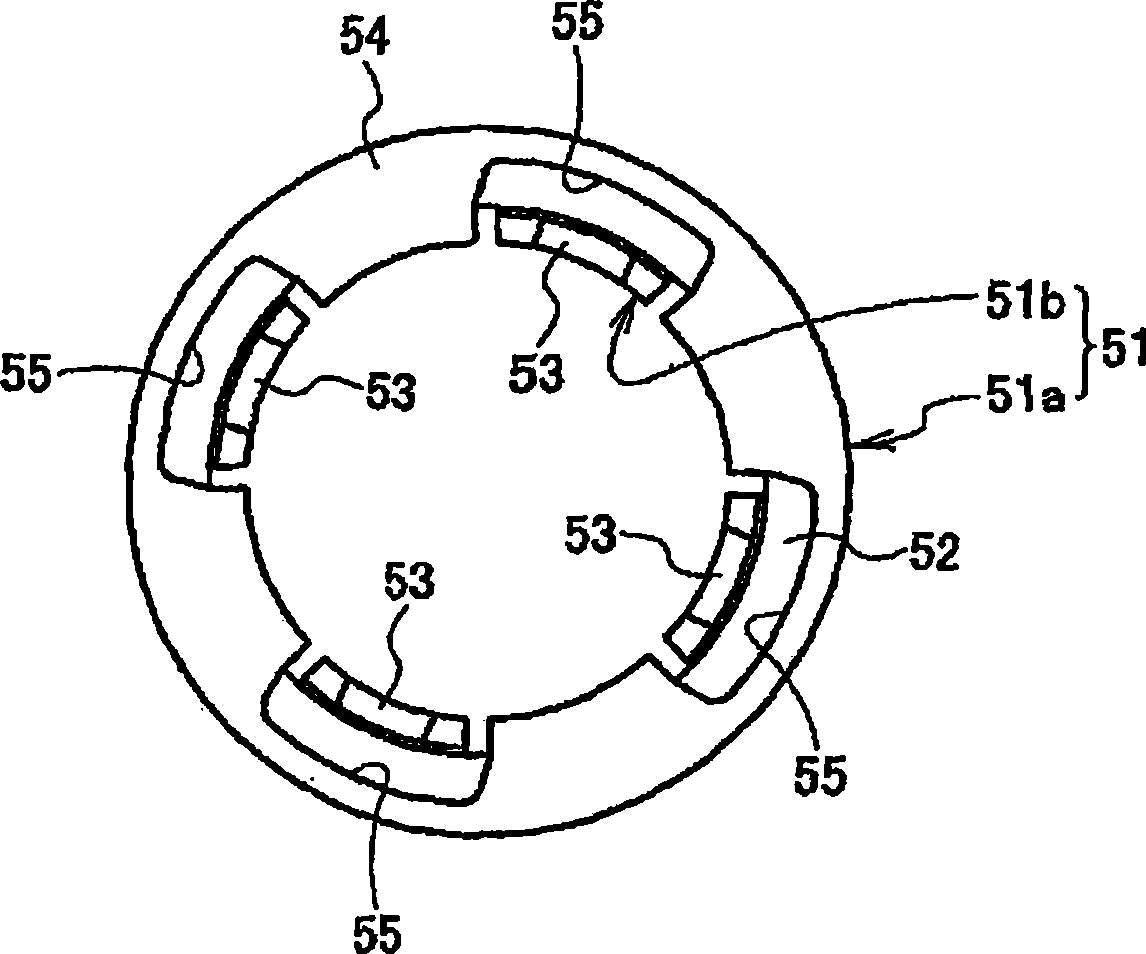

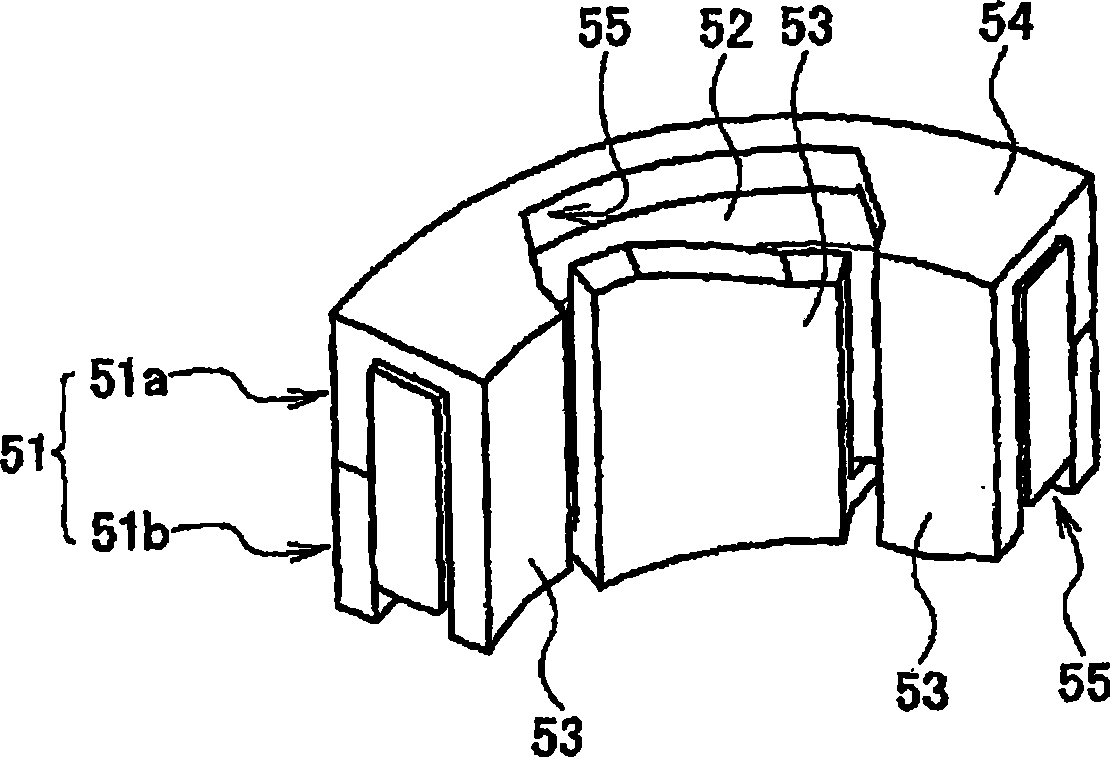

[0047] Like the first embodiment, the stator 5 includes an annular core 51 including a yoke and a plurality of claw poles 53 and an annular coil 52 housed in the core 51 . The yoke has a substantially C-shaped cross-sectional shape that is opened on an inner peripheral surface opposite to the rotor 4 . The yoke has a cylindrical side wall portion 56 for covering the outer peripheral surface of the loop coil 52 , and a pair of end surface portions 54 between which the loop coil 52 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap