Liquid constant-rate emitting apparatus and method of liquid constant-rate emission

A technology for discharging devices and liquids, which is applied in chemical instruments and methods, feeding devices, electrochemical generators, etc., and can solve the problems of needing a storage pump and increasing the size of the cost-increasing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

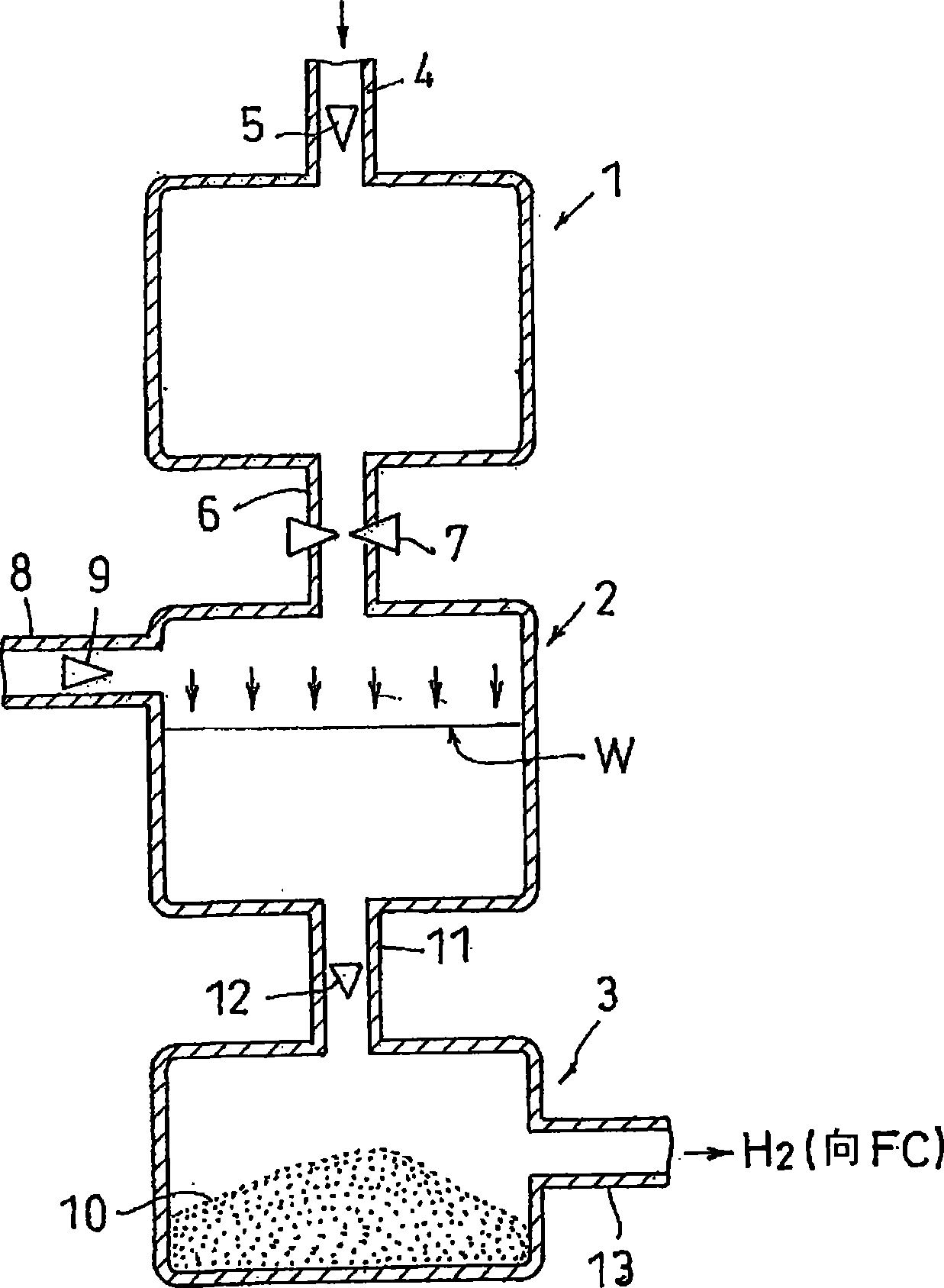

[0060] figure 1 It is a conceptual diagram showing the structure of the quantitative liquid discharge device of the first embodiment. This liquid quantitative discharge device has a gas storage container 1 and a liquid storage container 2 . Compressed air is stored in the gas storage container 1 . In addition, other gases such as nitrogen may be used instead of air. An introduction pipe 4 and a check valve 5 are provided on the upper wall of the gas storage container 1 , and air is introduced into the gas storage container 1 through the introduction pipe 4 . The amount of introduced air is, for example, about 3 cc, and it is stored in a state compressed to about 3 atmospheres. Any type can be applied as the check valve 5, but it is preferable to have a bird's beak (くちばし) that opens when the pressure on the primary side is higher than the pressure on the secondary side and closes when the pressure on the primary side is lower than the pressure on the secondary side, in addit...

no. 2 approach

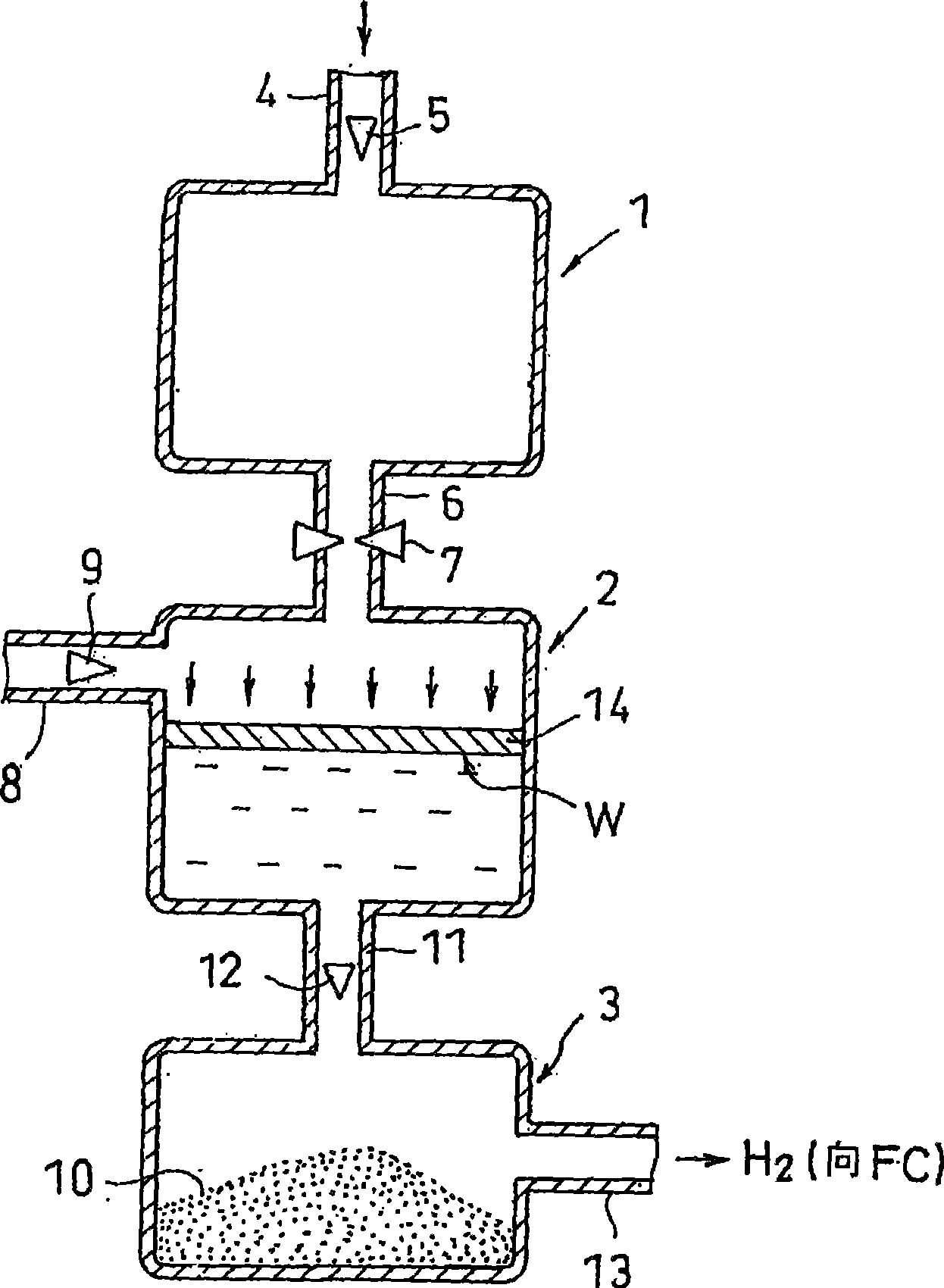

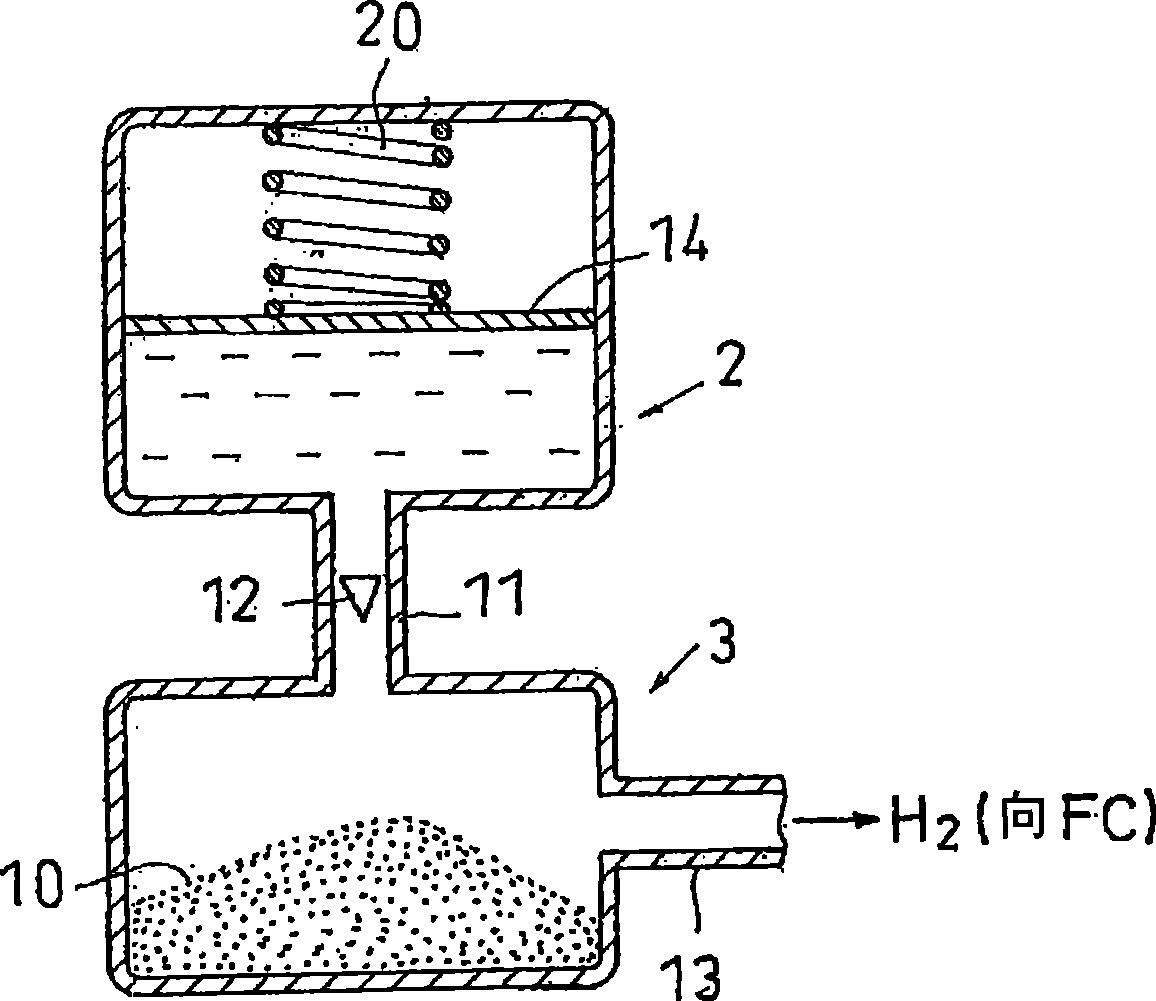

[0068] Next, according to figure 2 The configuration of the liquid quantitative discharge device according to the second embodiment will be described. with figure 1 The different points will be explained centering on it. figure 2 In the liquid storage container 2, a movable partition wall portion 14 arranged to partition the inside of the liquid storage container 2 is provided. As shown in the drawing, the movable partition wall part 14 is arranged above the water surface W, and the surface on the lower side of the movable partition wall part 14 and the water surface W is pressed by compressed air. By providing the movable partition wall portion 14, the water surface W can be squeezed more uniformly, and water can be discharged in a more stable quantity in a more stable state.

[0069] The movable partition wall portion 14 is a plate-shaped member, and can be formed of an appropriate material, for example, glass with good sliding properties can be used. In addition, by p...

no. 3 approach

[0074] Next, according to Figure 5 , Figure 6 Results of the liquid quantitative discharge device of the third embodiment will be described. The description will focus on points different from the first embodiment and the second embodiment. The structure of the injection valve B for injecting compressed air into the gas storage container 1 will be described. When using a liquid quantitative discharge device for a fuel cell of a portable device, it is preferable that the liquid quantitative discharge device be downsized, and the filling valve B itself is preferably as small as possible. In addition, in the case of the above-mentioned application, the compressed air to be injected is 2 to 3 cc and the pressure is about 0.3 to 0.5 MPa.

[0075] As the injection valve B, a valve having the same structure as the valve for injecting gas into the gas burner can be used. Its structure is as Figure 6 as shown, Figure 6 (a) shows the state where the valve is closed, and (b) sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com