Apparatus for blow moulding containers, comprising transport elements with two gripper arms

A blow molding, blow molding device technology, applied in the direction of household components, applications, household appliances, etc., to achieve the effect of simple controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

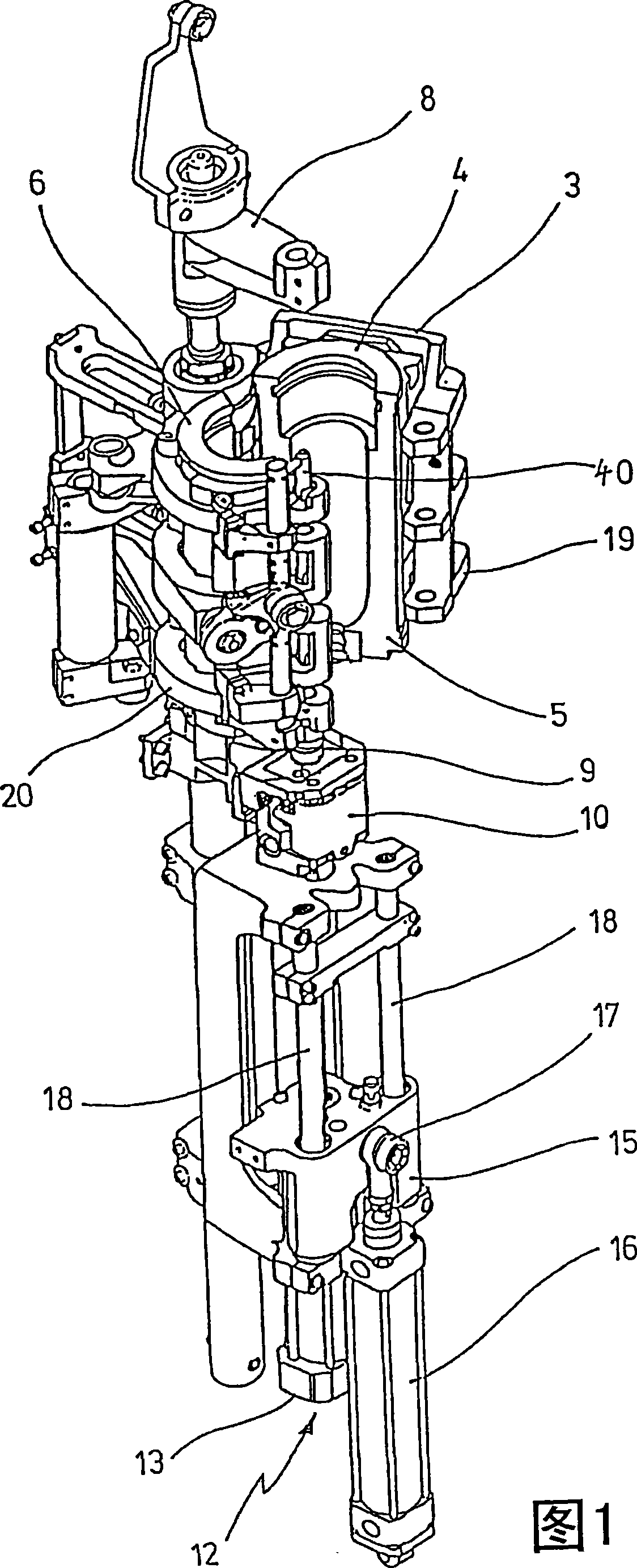

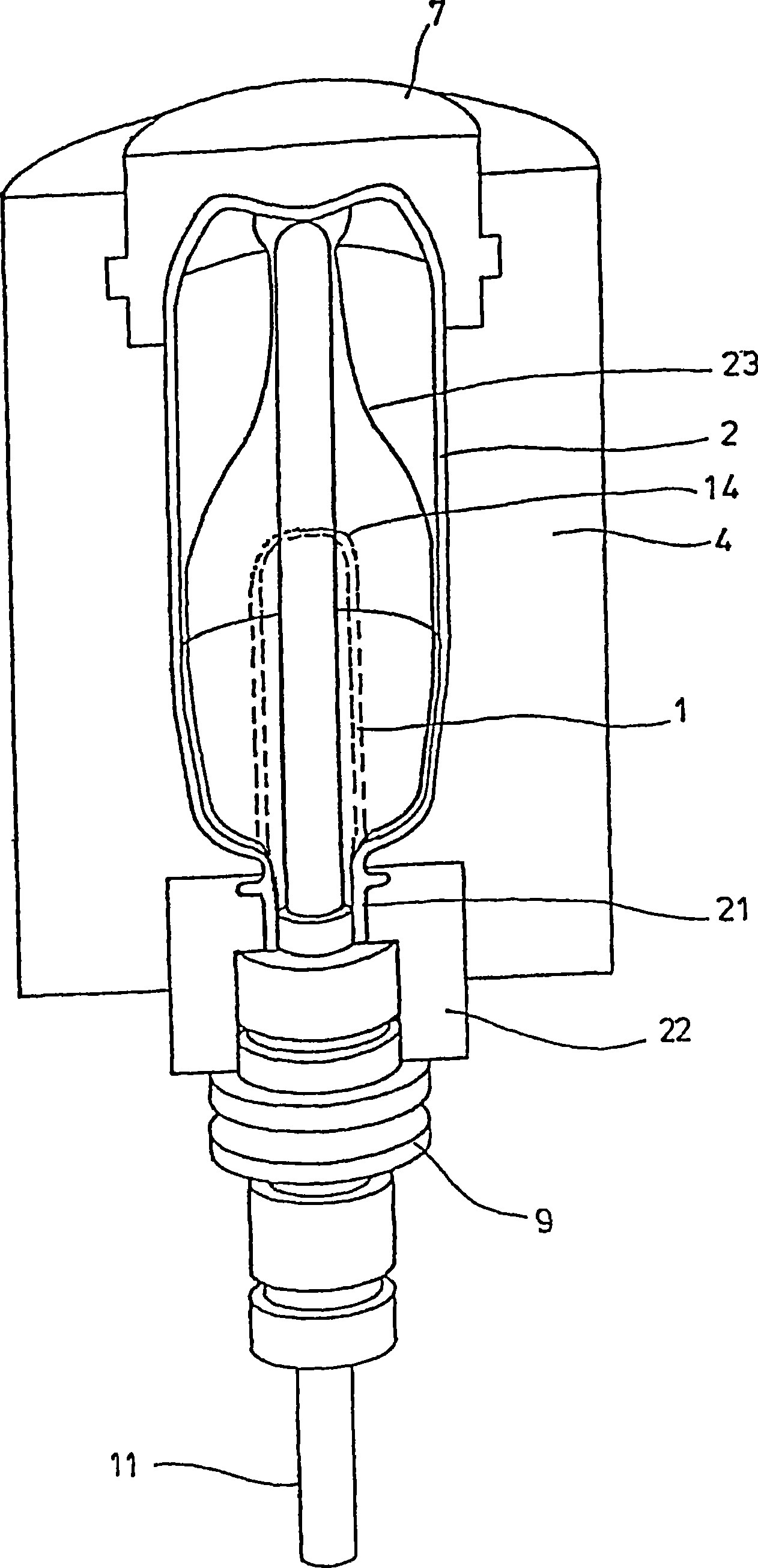

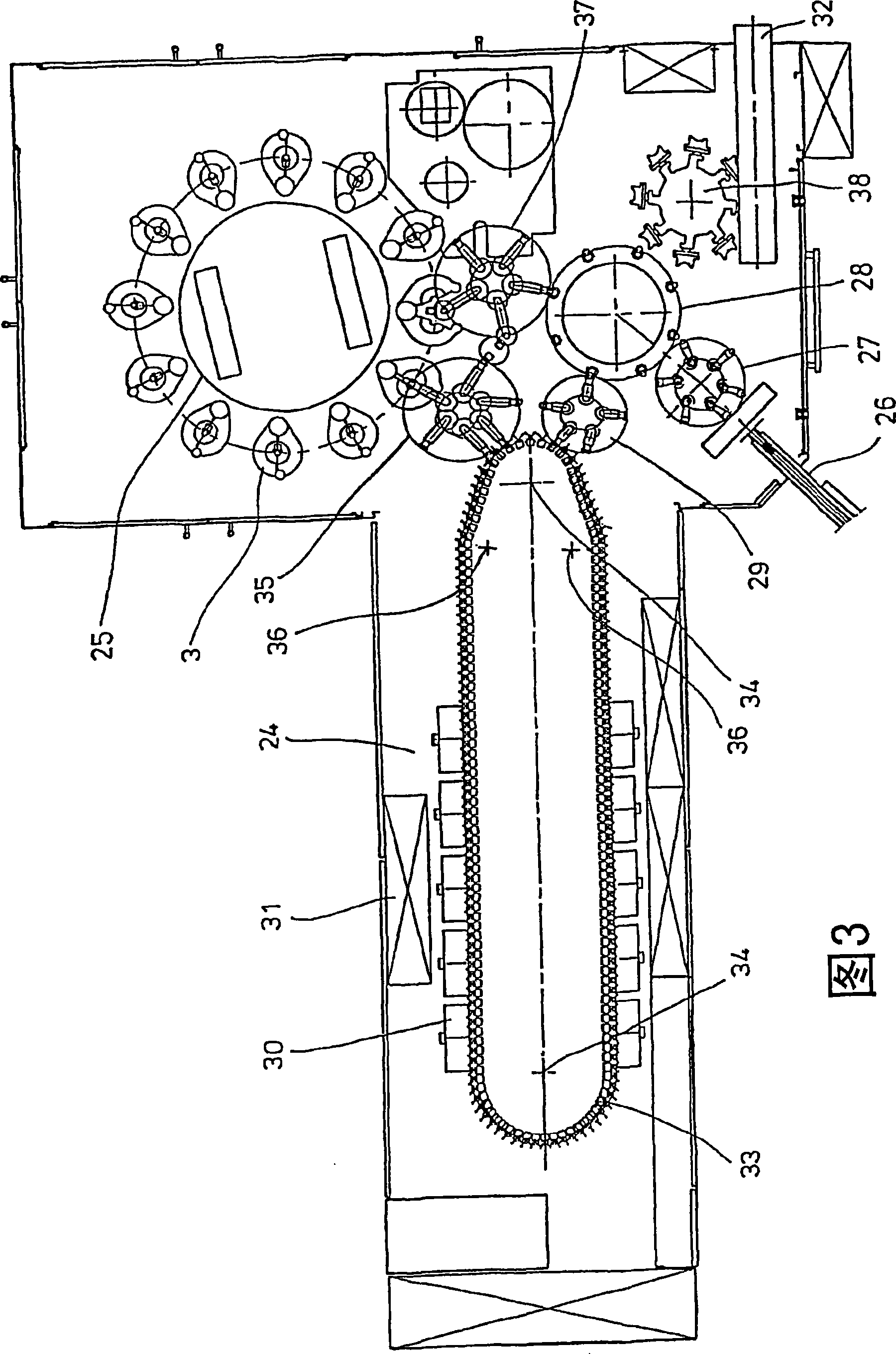

[0035] In Figure 1 and figure 2 The principle structure of a device for forming preforms 1 into containers 2 is shown in . It can be arranged as shown, or rotated 180° in a vertical plane.

[0036] The device for molding said container 2 essentially comprises a blow molding station 3 provided with a blow mold 4 into which the preform 1 can be inserted. The preform 1 may be an injection molded part made of polyethylene terephthalate. In order to allow the preform 1 to be inserted into the blow mold 4 and the finished container 2 to be removed, the blow mold 4 consists of mold halves 5, 6 and a bottom part 7 which can be lifted by a The device 8 is positioned. The preform 1 can be held in place by a holding element 9 in the region of the blow molding station 3 . It is possible, for example, to insert the preform 1 directly into the blow mold 4 by means of pliers or another operating mechanism.

[0037] For the introduction of compressed air, a connecting piston 10 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com