Open roof construction

A roof and vehicle technology, applied to superstructures, superstructure subassemblies, roofs, etc., can solve problems such as panels cannot be locked, cannot be properly joined, and the height of the curved part cannot be reached

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

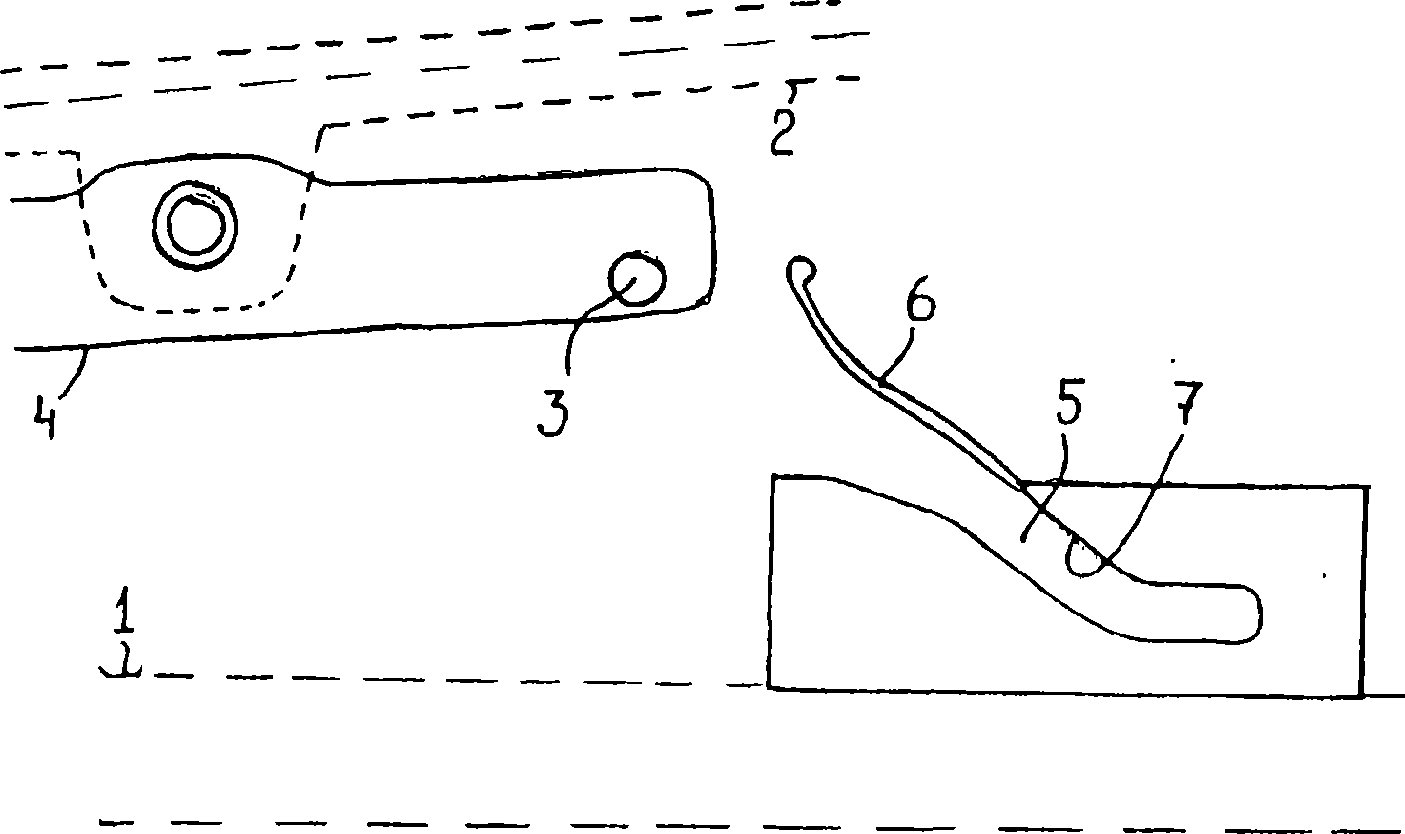

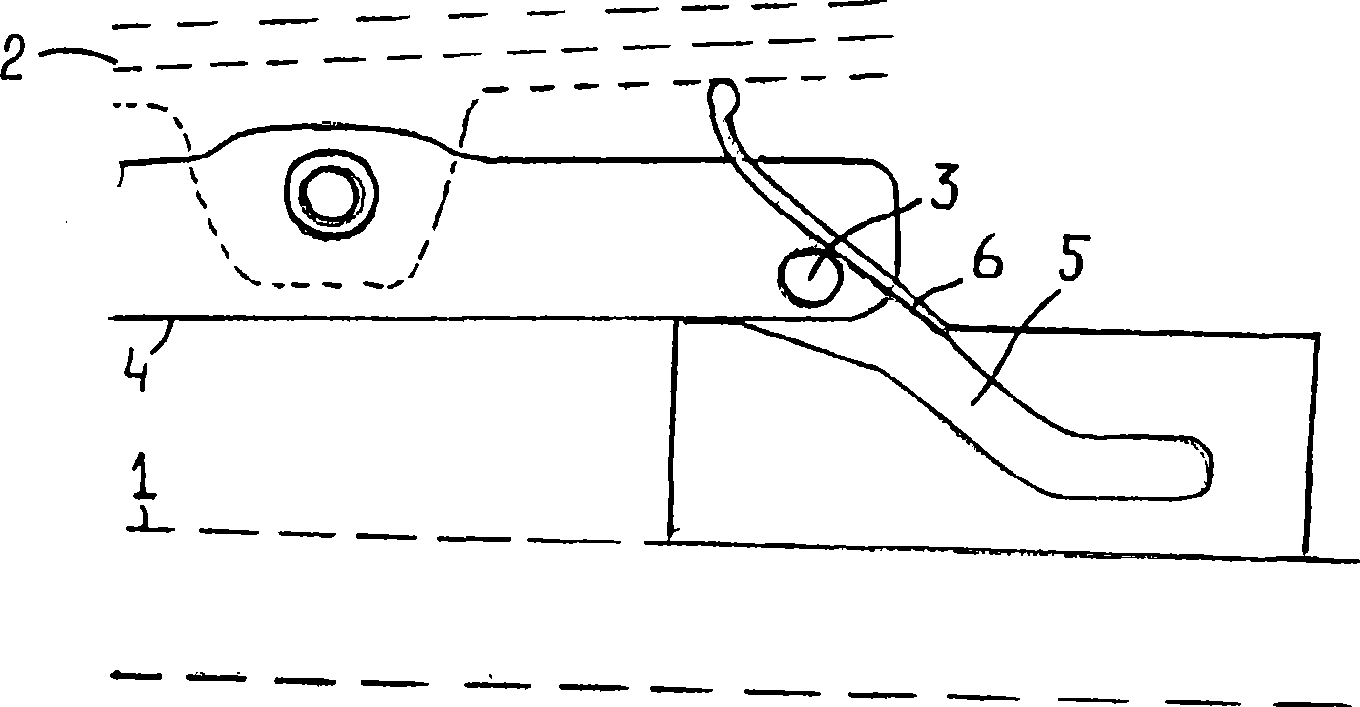

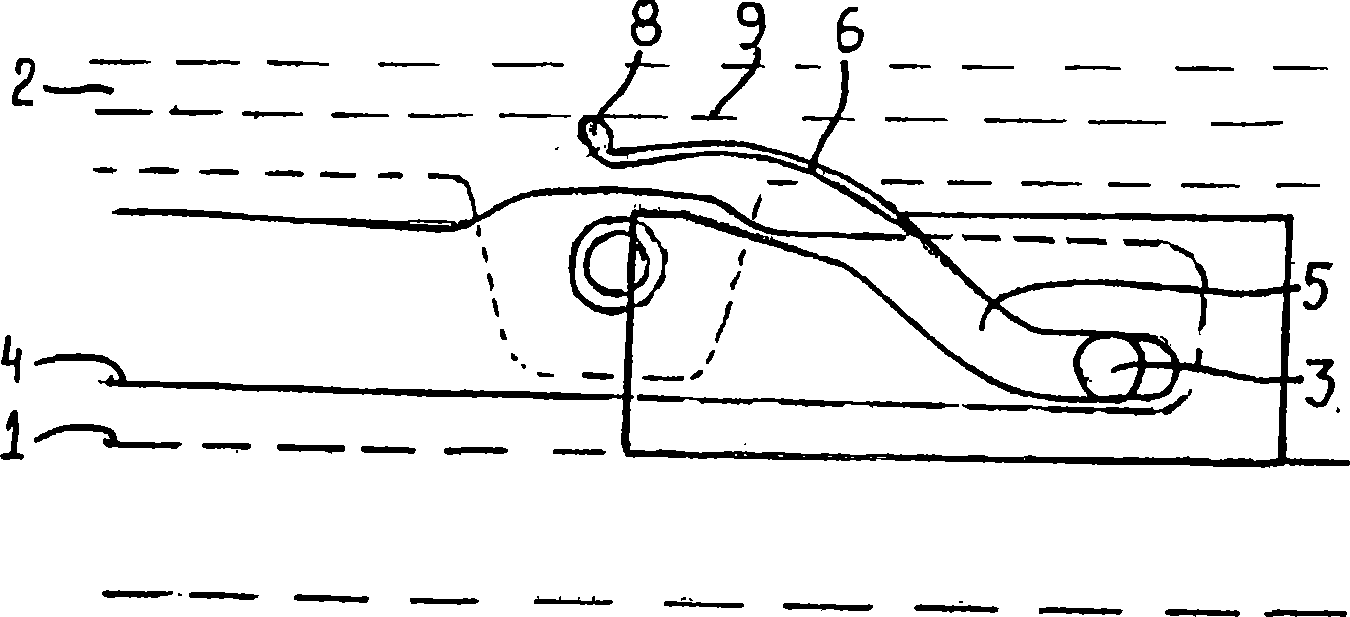

[0016] First refer to figure 1 , the open roof structure portion of a vehicle is shown schematically in cross-sectional view and in an open position. Indicated by dashed lines is the structural roof part 1 which is connected (in a manner not shown in detail) to a fixed roof part (not shown here). In a manner known per se, but not shown, an open roof is provided in the fixed roof part of the vehicle and can be opened and closed by means of a panel 2 (only schematically indicated by dotted lines). The panel 2 can be slid and tilted to open and close the open roof by means of an operating mechanism, not shown here but known per se to those skilled in the art.

[0017] Panel 2 is provided with guide pin 3 (this guide pin can be directly or indirectly connected with panel, for example, as figure 1 shown, connected via bracket 4). The structural roof part 1 is provided with a bend 5 for guiding the guide pin 3 . The function of the assembly of the guide pin 3 and the bend 5 is t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap