Automatic monitoring apparatus for preventing side running of belt conveyer

An automatic monitoring and belt conveyor technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., to achieve the effect of reducing personnel input, labor intensity, and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

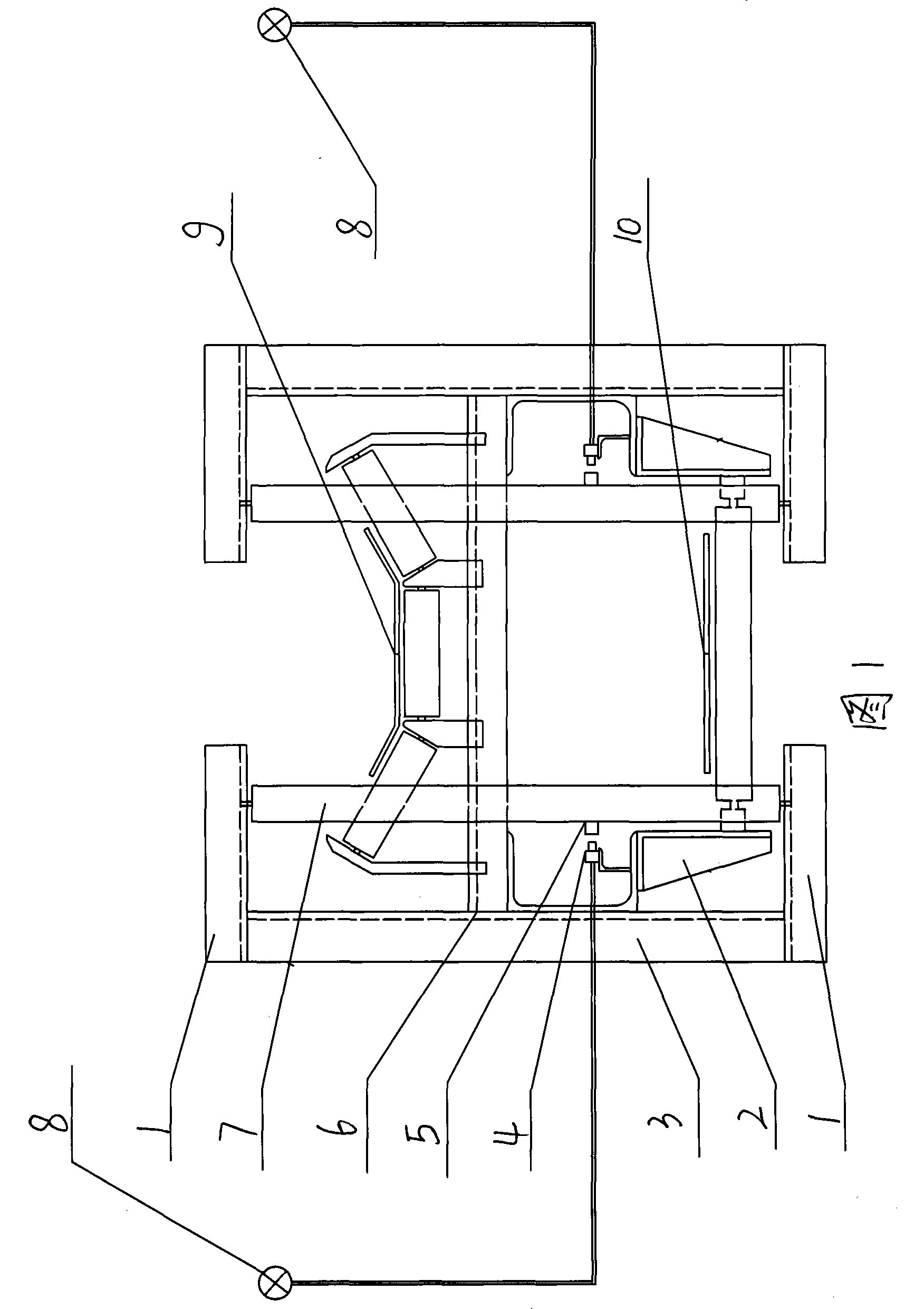

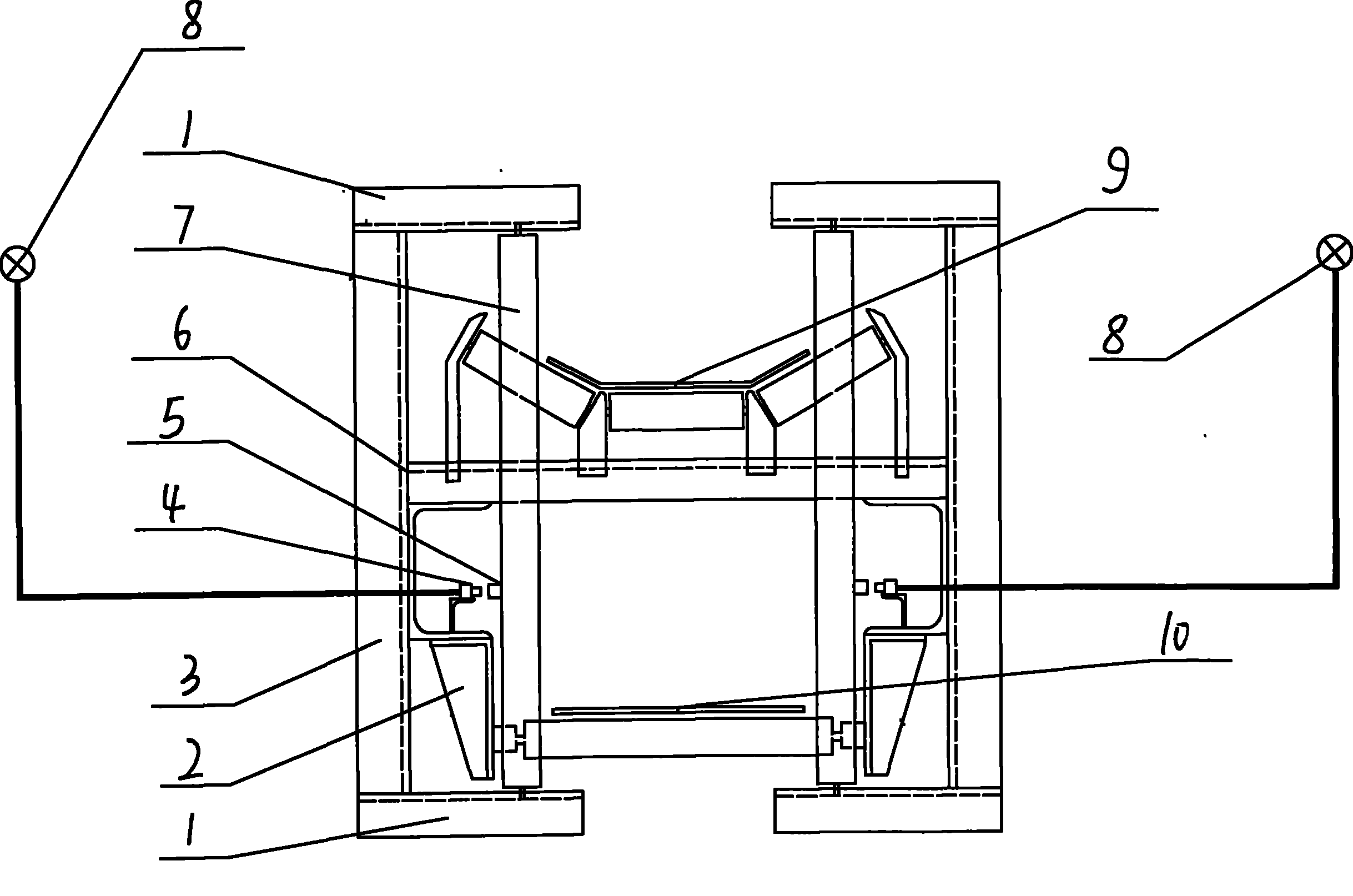

[0013] As shown in Figure 1, the present invention installs a roller bracket 6 on the truss of the belt conveyor, the roller bracket 6 is made of a vertical beam 3 and a crossbeam 1 fixed at the two ends of the vertical beam 3, the two crossbeams 1 are parallel to each other, and the roller Support 6 can adopt the angle iron of ∠45 * 45 to make, and vertical beam is long 1170mm, and crossbeam is long 250mm, is welded into retaining roller support. Between the two crossbeams 1 parallel to the vertical beam 3 and between the lower lug 2 of the belt conveyor and the belt, a retaining roller 7 is installed. The retaining roller 7 is a circular drum with a length of 1150 mm and a diameter of Ф108 mm. The two ends of the shaft are respectively installed on the beam 1, and the retaining roller can rotate. Install a XZ-A / D type slip switch 4 with a probe on the truss, and weld a slip switch detection block 5 in the middle of the stop roller 7 to align with the probe of the slip switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com