Horizontal strip type fluidization distributor

A material distribution device and strip-type technology, which is applied in the directions of transportation and packaging, conveying bulk materials, chemical instruments and methods, etc., can solve the problem of poor material distribution effect, and achieve the effects of easy implementation, improved purification efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structure of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

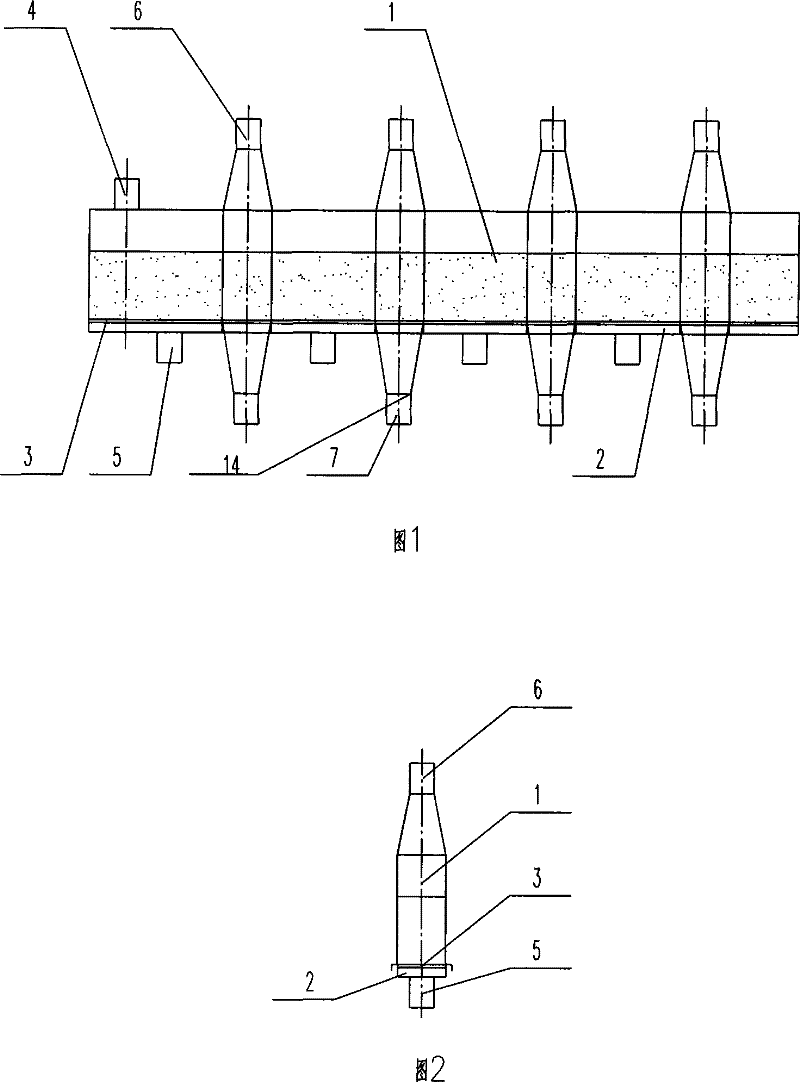

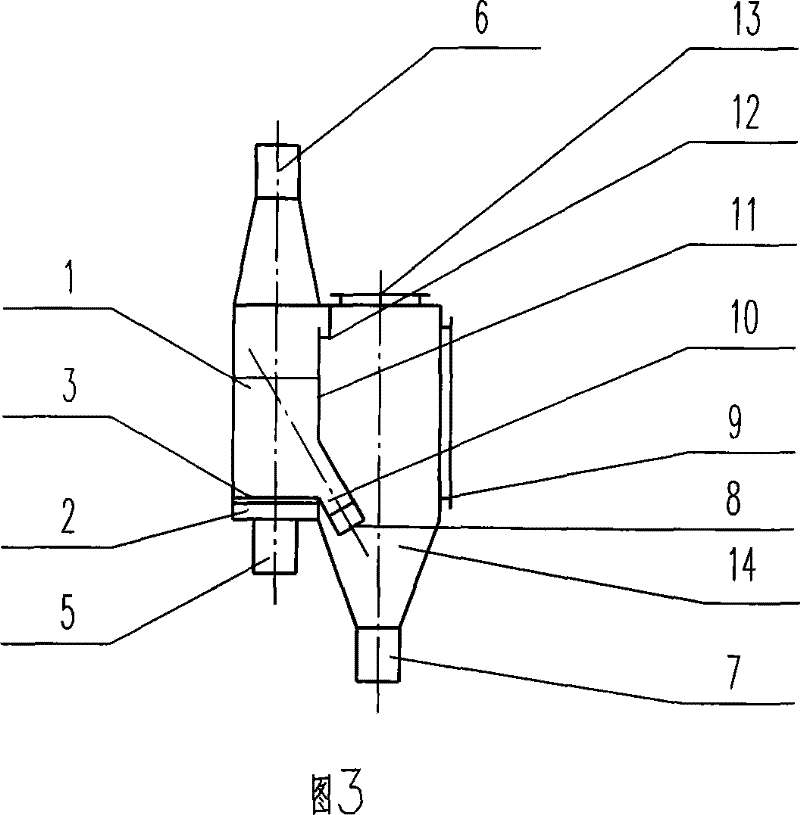

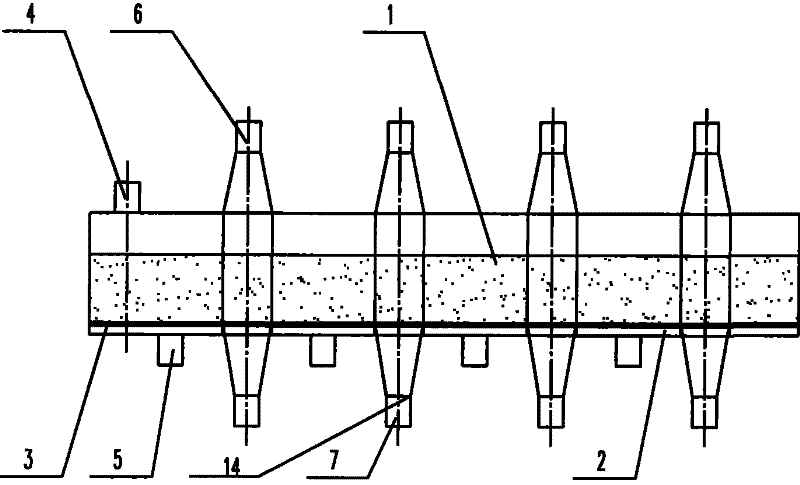

[0025] Such as figure 1 As shown, the structure of the horizontal strip type fluidized material distribution device is as follows: the material chamber 1 is arranged horizontally or close to the horizontal, and the installation angle of the material chamber 1 is preferably between -1° and 1°; The lower end is connected to the air chamber 2, the material chamber 1 and the air chamber 2 are separated by a breathable plate 3, 1-20 feeding ports 4 are set on the material chamber 1, and the feeding ports 4 are set at any position on the upper part or side of the material chamber 1; At least two distributing boxes 14 that can be independently discharged are installed on the material chamber 1. The material chamber 1 communicates with the material distributing boxes 14 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com