Application of electrothermic material in building waterproofing

An electrothermal material and building technology, applied in the processing of building materials, construction, building components, etc., can solve the problems of difficult waterproof engineering quality, high labor intensity, low work efficiency, etc., so as to reduce the labor intensity of workers and improve work efficiency. , to solve the effects that are not easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

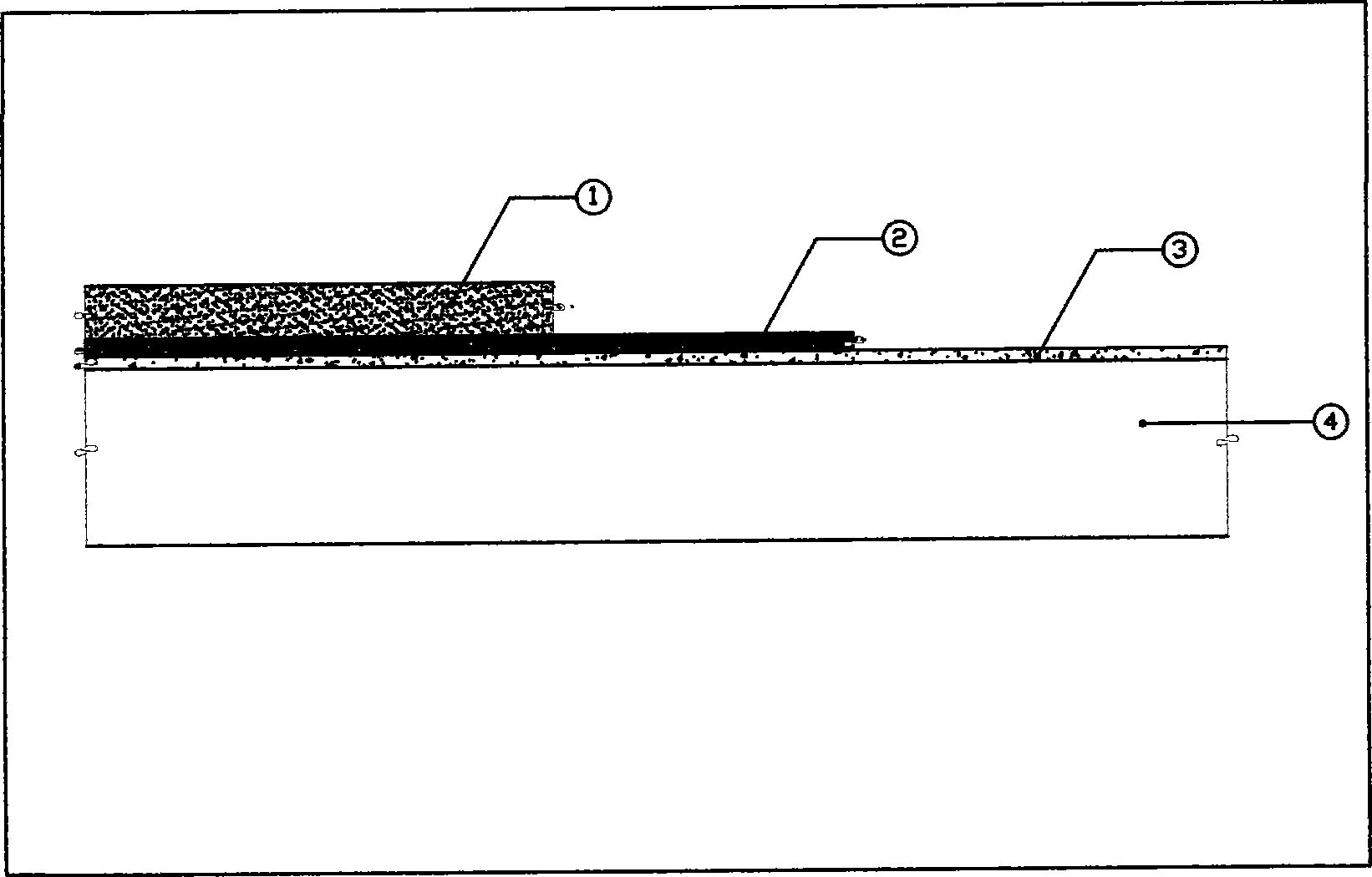

[0011] In Fig. 1, the electrothermal material (2) is preset on the treated building waterproof base surface (3), and then the waterproof material (1) is laid on the electrothermal material layer. The fusible adhesive material can be attached to the lower surface of the waterproof material (1), it can be attached to the electric heating material (2), it can be applied on the surface of the base layer of the building (3), or it can be carried out on a separate layer of the fusible adhesive material. Laying on the upper or lower surface of the electric heating material (2). The waterproof material (1), the fusible adhesive material and the electric heating material (2) can be processed into one body to form an electrified self-adhesive coiled material. After the materials are laid according to Figure 1, connect the conductive lines and electrodes, and then turn on the electricity. After the electricity is turned on, the electrothermal material (2) will heat up to a certain temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com