Method for monitoring oil, water well sleeve axial strain by using optical fibre Brillouin sensor

An optical fiber strain and axial strain technology, applied in the direction of using optical devices, measurement, instruments, etc., can solve the problems of not being able to monitor the casing damage point of the whole well section, difficult to adapt to the harsh conditions of the well, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

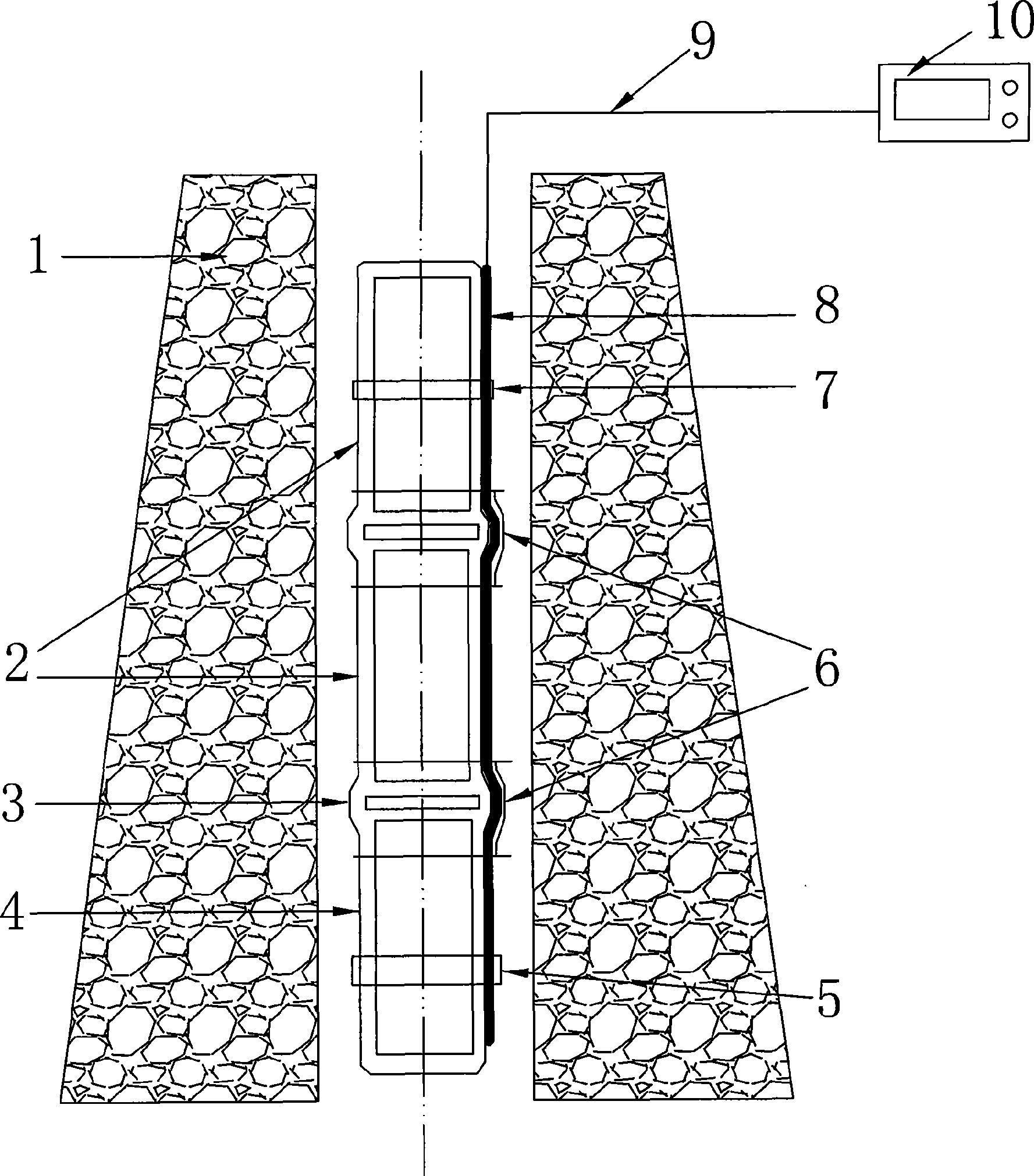

[0030] The present invention will be further described below in conjunction with accompanying drawing:

[0031] The method described in the present invention is based on the principle of optical fiber Brillouin sensing, that is, during the transmission of light, photons and irregular microscopic particles in the optical fiber have inelastic collisions to generate Brillouin scattering. The frequency of the Brillouin scattered light will produce a Brillouin frequency shift. The optical fiber Brillouin sensor manufactured based on the optical fiber Brillouin sensing principle has been applied in many fields, but the application in the field of oilfield casing damage is indeed the first time that the present invention involves, and the specific composition of the method is as follows:

[0032] ① The fiber-optic Brillouin sensor encapsulated in fiber-reinforced resin goes downhole with a single oil and water well casing, and is arranged axially along the string of oil and water wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com