Three-stage gear transmission device

A technology of gear transmission and large gear, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc., and can solve the problems of high manufacturing cost, high cost, and difficulty in manufacturing internal gears of gearboxes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

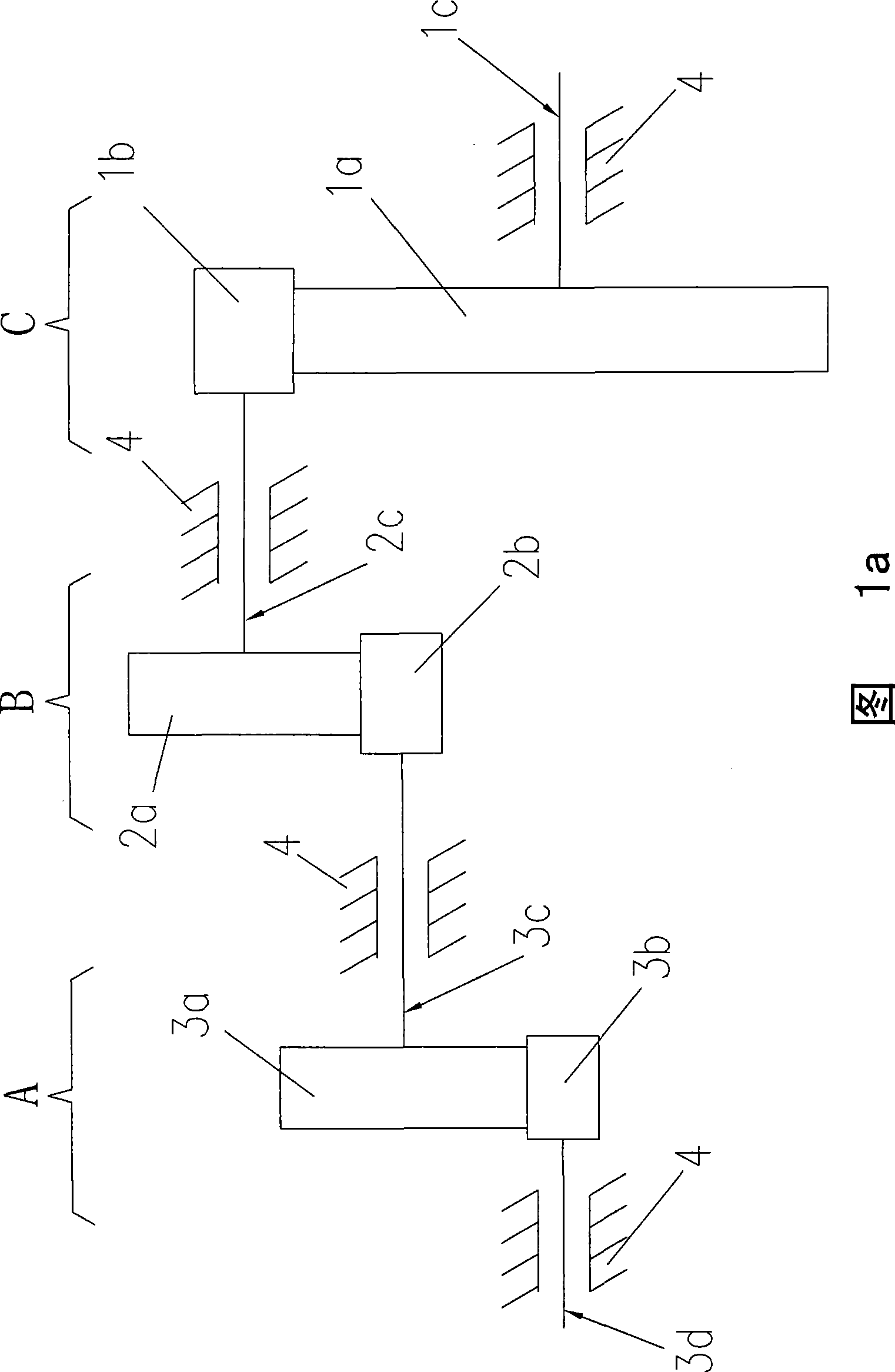

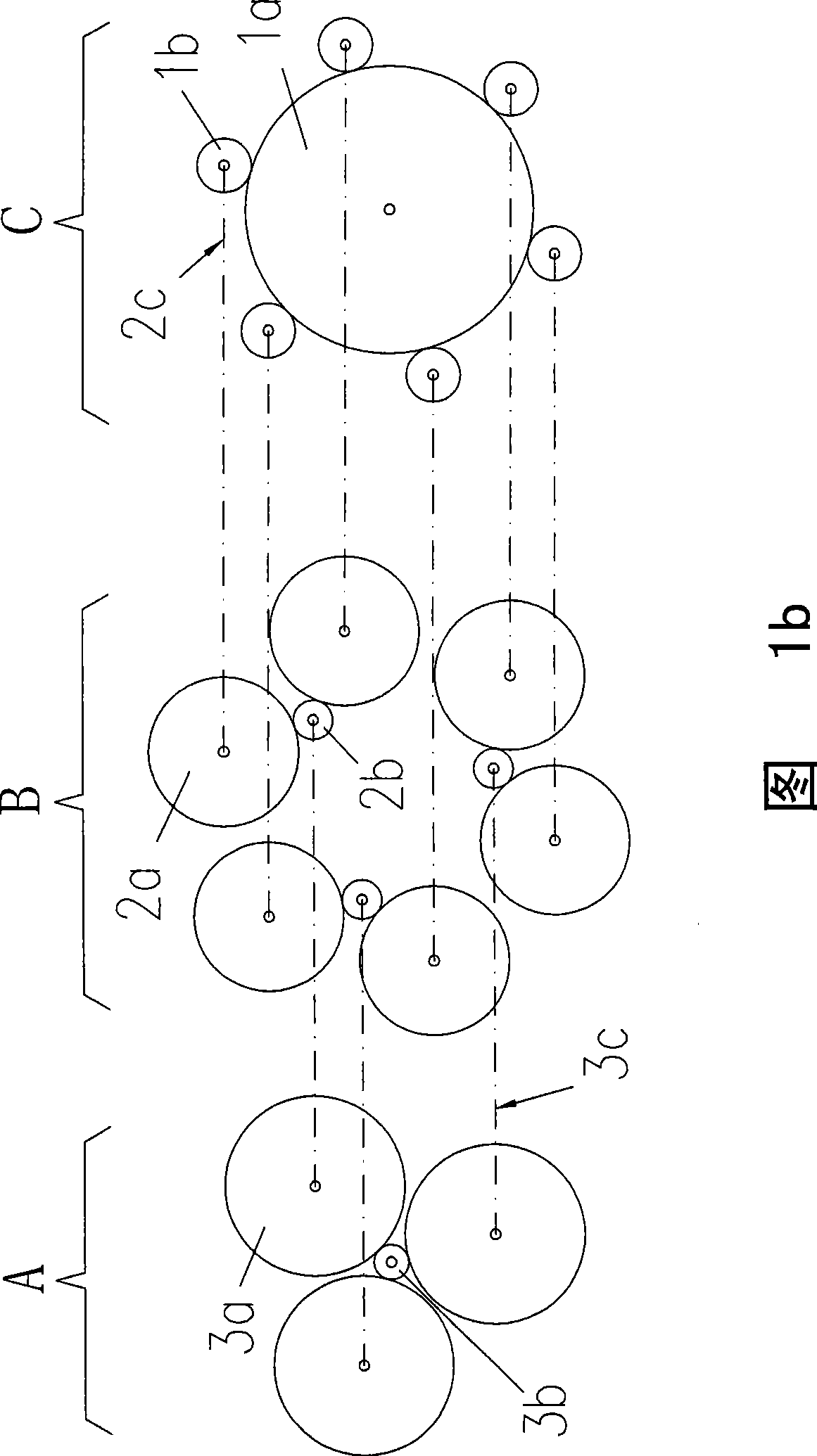

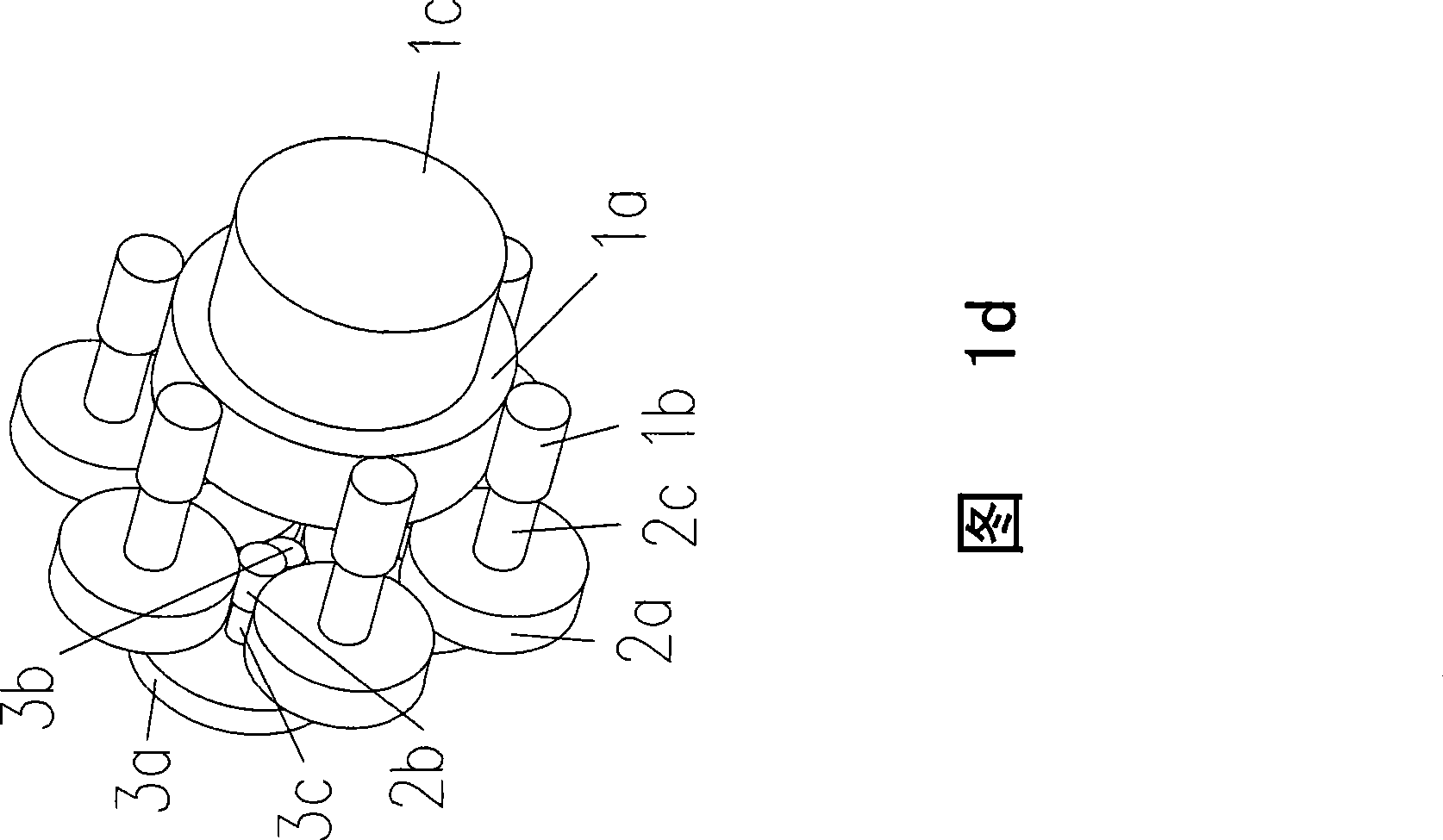

[0029] As shown in Fig. 1a, Fig. 1b, Fig. 1c and Fig. 1d, the first embodiment of the present invention includes a case body 4, a low-speed shaft 1c, a low-speed large gear 1a, six low-speed pinions 1b, six medium Speed stage connecting shaft 2c, six medium-speed stage large gears 2a, three medium-speed stage pinion gears 2b, three high-speed stage connecting shafts 3c, three high-speed stage large gears 3a, one high-speed stage pinion gear 3b and one high-speed shaft 3d; wherein, the low-speed shaft 1c is connected with the low-speed large gear 1a, and the low-speed large gear 1a is an external gear or an internal gear. In the low-speed stage, the low-speed large gear 1a is simultaneously distributed with six low-speed pinions 1b meshing, six low-speed pinion gears 1b are respectively connected with six medium-speed gears 2a through six medium-speed coupling shafts 2c; at medium-speed, six medium-speed gears 2a are divided into three groups, each group It includes two mediu...

no. 2 example

[0036] As shown in Fig. 2a, Fig. 2b, Fig. 2c and Fig. 2d, the second embodiment of the present invention includes a case body 42, a low-speed shaft 12c, a low-speed gear 12a, six low-speed pinions 12b, six medium Speed stage coupling shaft 22c, six medium-speed stage large gears 22a, three medium-speed stage pinions 22b, three high-speed stage coupling shafts 32c, three high-speed stage large gears 32a, one high-speed stage pinion 32b, one high-speed shaft 32d and a planetary carrier 52; wherein, the planetary carrier 52 is rotatably arranged relative to the casing 42, for example, the planetary carrier 52 is arranged on the casing 42 through a self-aligning bearing, and the low-speed shaft 12c is connected with the planetary carrier 52 and connected with the planetary carrier 52 Rotate synchronously, the high-speed shaft 32d and the low-speed shaft 12c are mounted on the casing 42 through bearings, the low-speed gear 12a is fixedly arranged relative to the casing 42, and the...

no. 3 example

[0044]Fig. 3a, Fig. 3b, Fig. 3c and Fig. 3d show the third embodiment of the present invention, which includes a box body 43, a low-speed shaft 13c, a low-speed stage bull gear 13a, twelve low-speed stage pinions 13b, ten Two medium-speed stage connecting shafts 23c, twelve medium-speed stage bull gears 23a, six medium-speed stage pinion gears 23b, six high-speed stage connecting shafts 33c, six high-speed stage bull gears 33a1 and 33a2, one first high-speed stage stage pinion 33b1, a second high-speed stage pinion 33b2 and a high-speed shaft 33d; wherein, the low-speed shaft 13c is connected with the low-speed bull gear 13a, and the low-speed bull gear 13a is an external gear or an internal gear. In the low-speed stage, a low-speed The first stage bull gear 13a meshes with twelve low-speed stage pinions 13b distributed along its periphery at the same time, and the twelve low-speed stage pinions 13b are respectively connected to twelve medium-speed stage bull gears 23a through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com