Tool plate and test method using the same

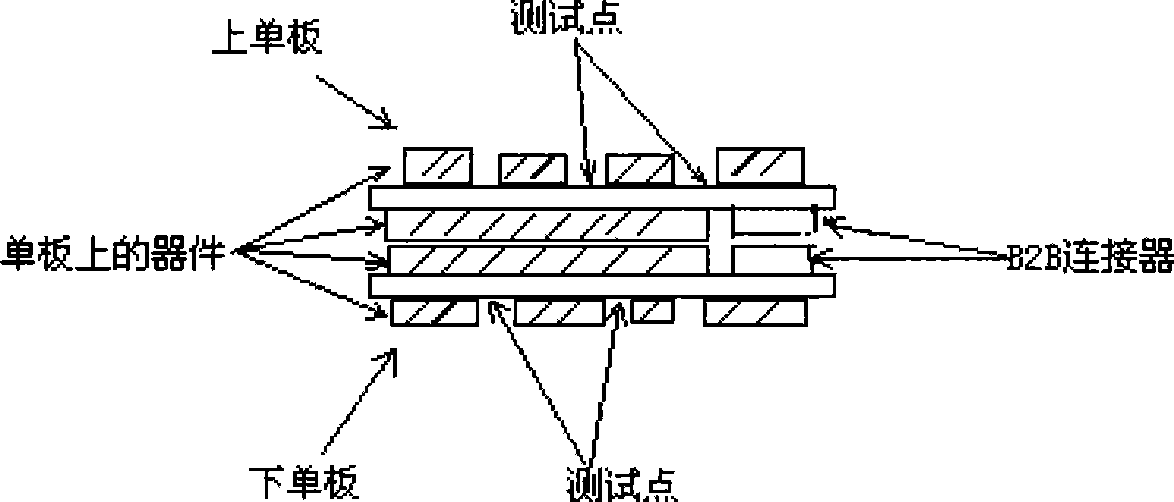

A tool and test point technology, applied in the field of testing, can solve problems affecting the miniaturization of electronic products, and achieve the effects of reducing design difficulty and production cost, increasing service life, and reducing production and testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above features and advantages of the embodiments of the present invention more obvious and understandable, the embodiments of the present invention will be described in detail below in conjunction with specific implementations.

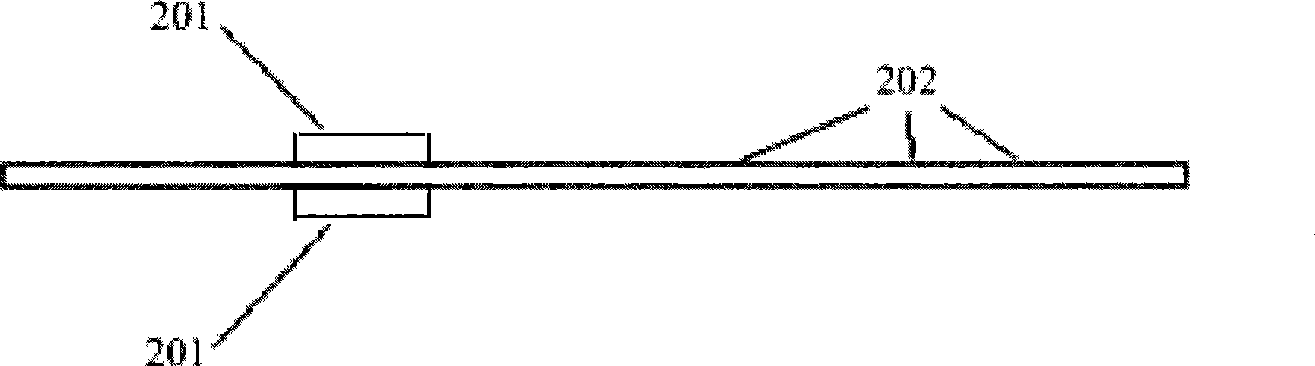

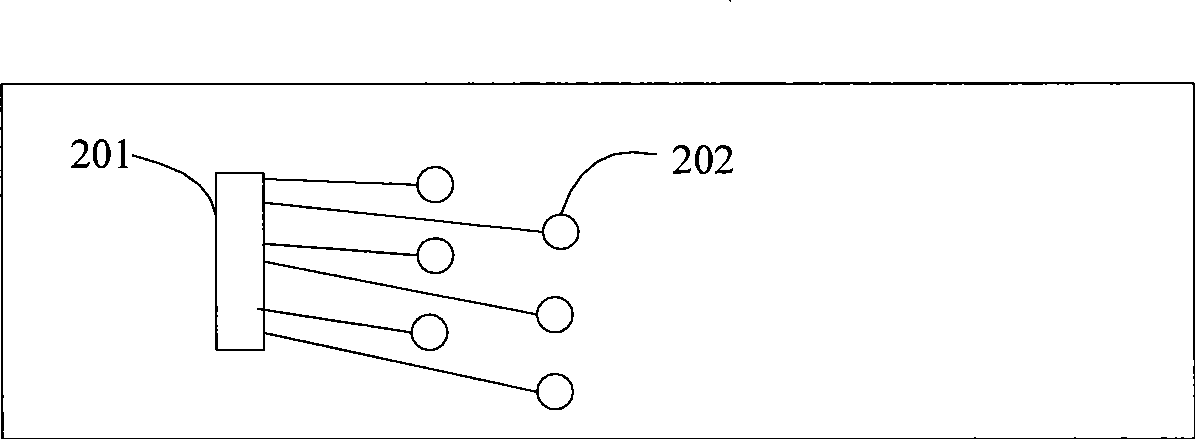

[0023] Please refer to Fig. 2 (a), which is a side view of the tool board structure of the embodiment of the present invention, please refer to Fig. 2 (b), which is a top view of the tool board structure of the embodiment of the present invention, the tool board of the embodiment of the present invention may include:

[0024] At least one connector 201: matching with the connector on the single board, leading the test signal of the single board to at least one test point without affecting the function of the single board;

[0025] At least one test point 202: arranged on the tool board, for providing the test signal to the test pin.

[0026] The tool board shown in Fig. 2 will be described in detail below.

[0027] The too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com