Array substrate of LCD

A liquid crystal display, array substrate technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of reducing the performance of left and right viewing angles, light leakage, and reducing the aperture ratio, and achieve the effect of avoiding light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

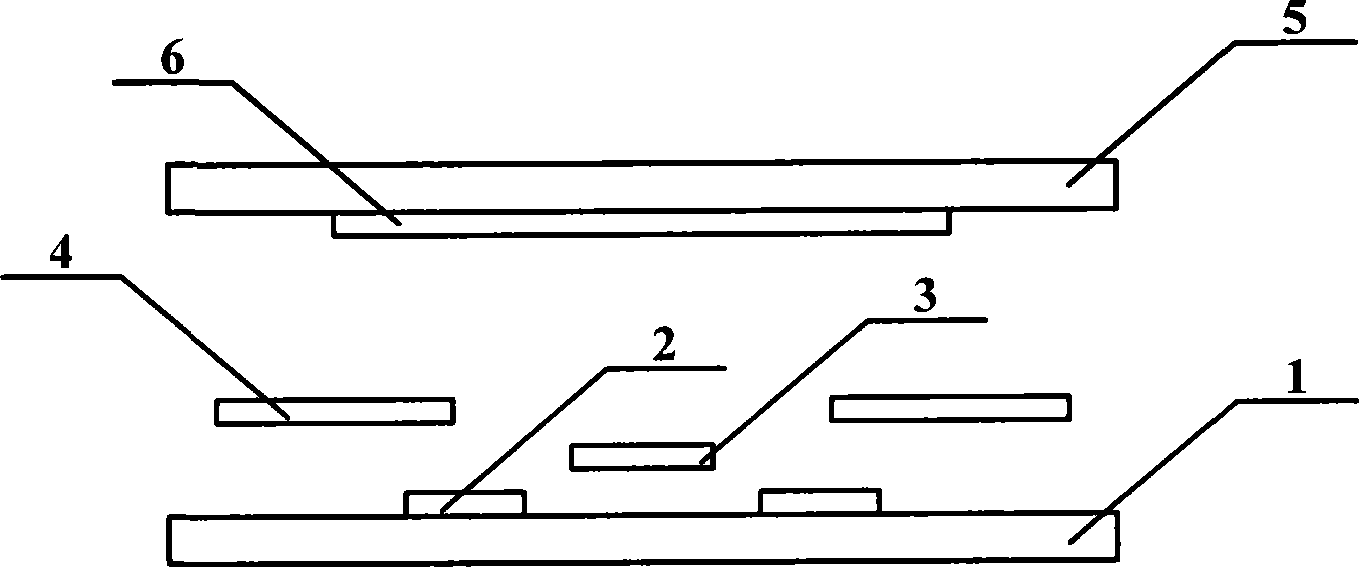

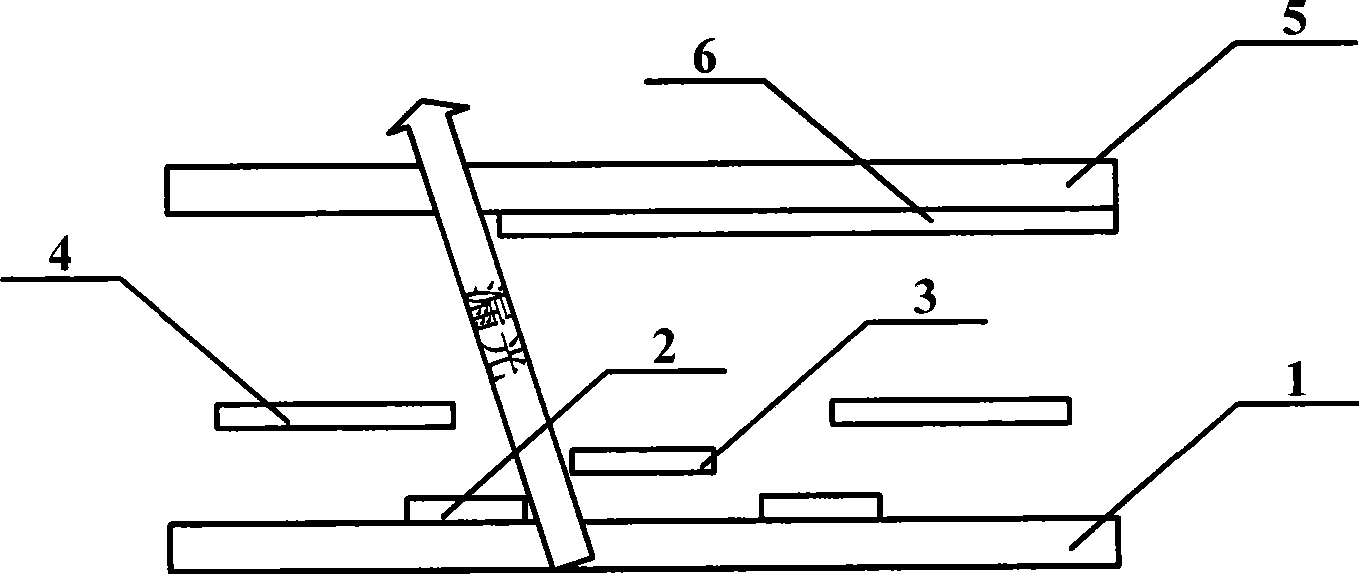

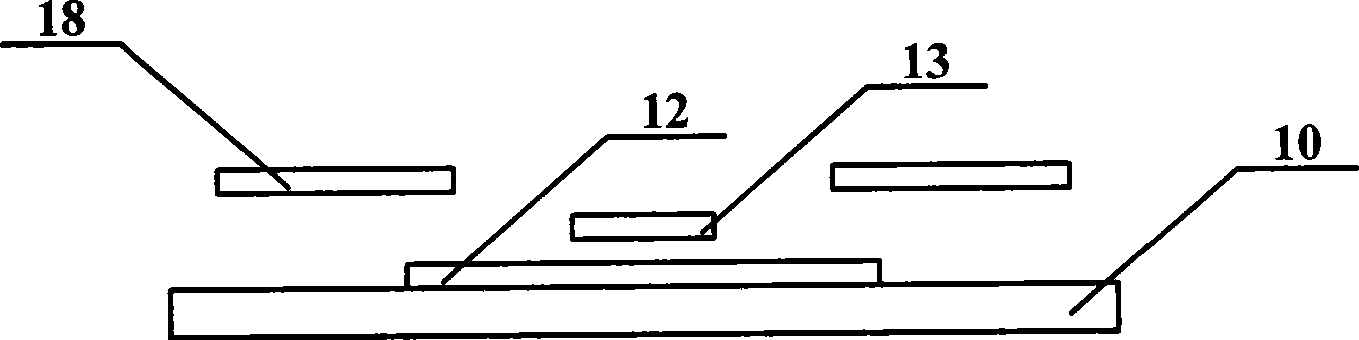

[0011] Such as image 3 As shown, it is a schematic cross-sectional structure diagram of the data line direction of the specific embodiment of the array substrate of the liquid crystal display of the present invention. This embodiment includes a substrate 10, on which gate lines (not shown) and data lines 13 intersecting each other to define a pixel area are provided, and a pixel electrode 18 is provided in the pixel area, wherein: the data lines Shielding strips 12 are arranged in parallel directly below, and the width of the shielding strips 12 is greater than that of the data lines 13 .

[0012] In the present invention, the shielding bar with a width greater than the width of the data line is arranged in parallel directly under the data line, so that no light leakage occurs around the data line, and the light leakage that may occur when the panel is tapped is effectively avoided.

[0013] In order to further avoid short-circuit and disconnection of the data line, in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com