Thinning method for backing side of wafer

A backside thinning and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as wafer edge bending and fracture, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

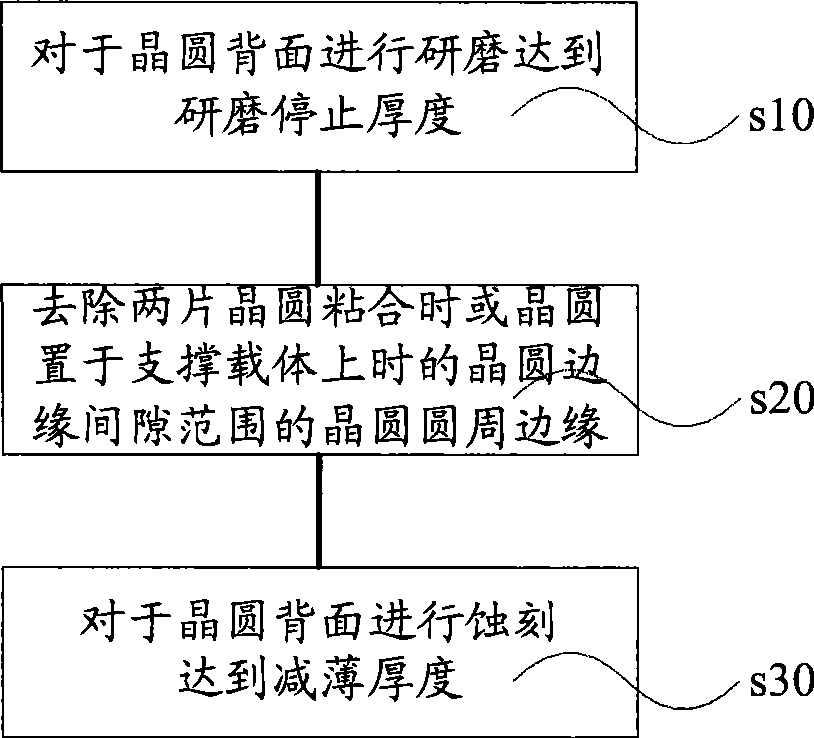

[0062] Refer to image 3 As shown, another embodiment of the wafer backside thinning method of the present invention includes the following steps:

[0063] Step s10, grinding the back of the wafer to reach the grinding stop thickness;

[0064] Step s20, removing the peripheral edge of the wafer in the wafer edge gap range when the two wafers are bonded or when the wafer is placed on the support carrier;

[0065] Step s30, etching the backside of the wafer to reduce the thickness.

[0066] Each step will be further explained below.

[0067] For step s10, the grinding stop thickness is 100 to 200um.

[0068] For step s20, an etching method is used to remove the peripheral edge of the wafer in the gap range of the wafer edge when the two wafers are bonded or when the wafer is placed on the support carrier. In addition, the above-mentioned etching method is a method of ion reactive etching.

[0069] The ion reactive etching method includes the following steps:

[0070] Form a photoresis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com