Electric core package clip

A battery cell and fixture technology, which is applied in the field of clamping battery cell entry fixtures, can solve problems such as difficult adjustment, difficult to achieve technical effects, and difficult manufacturing, and achieve the effects of easy adjustment, avoiding stuck situations, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

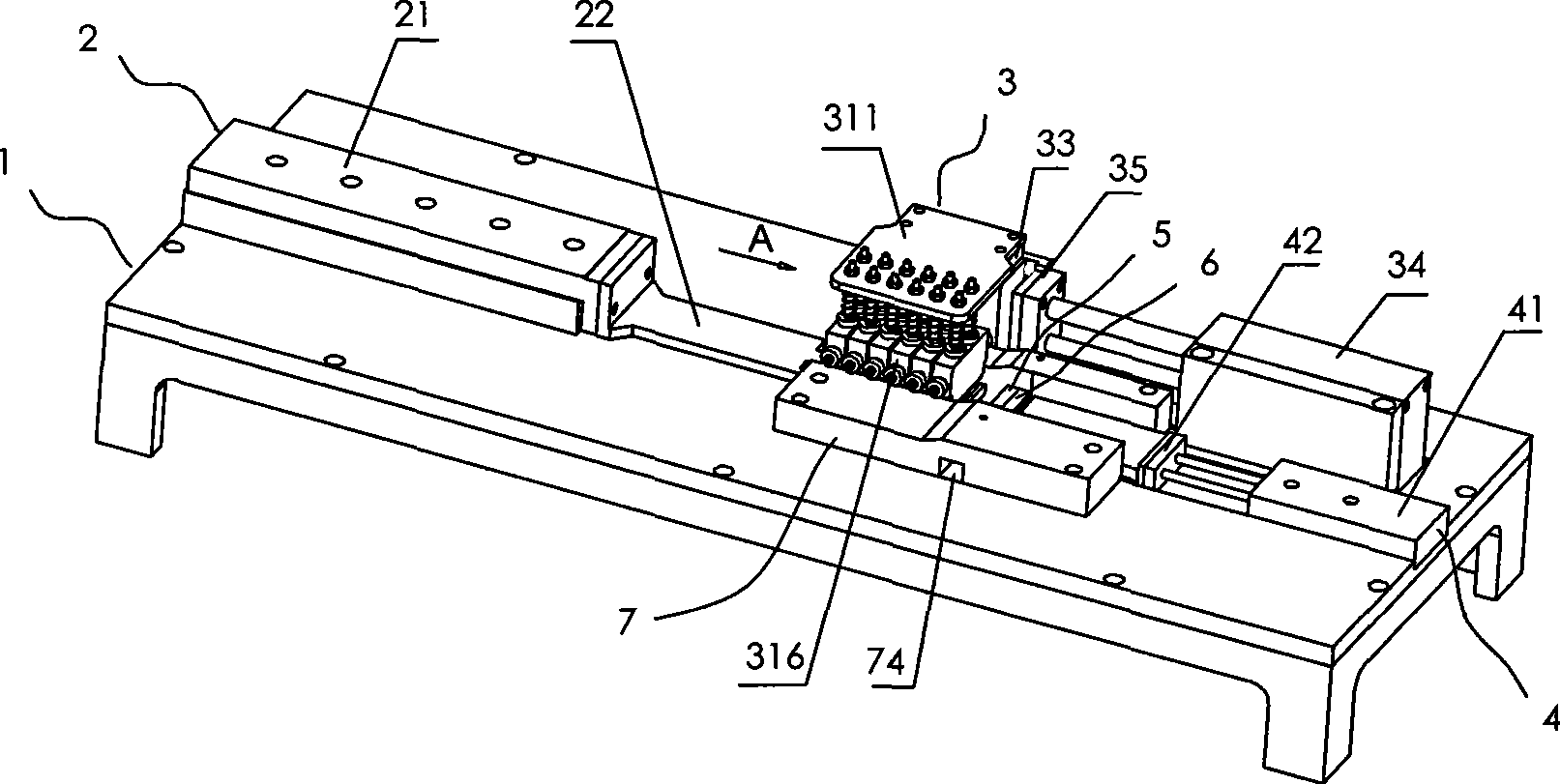

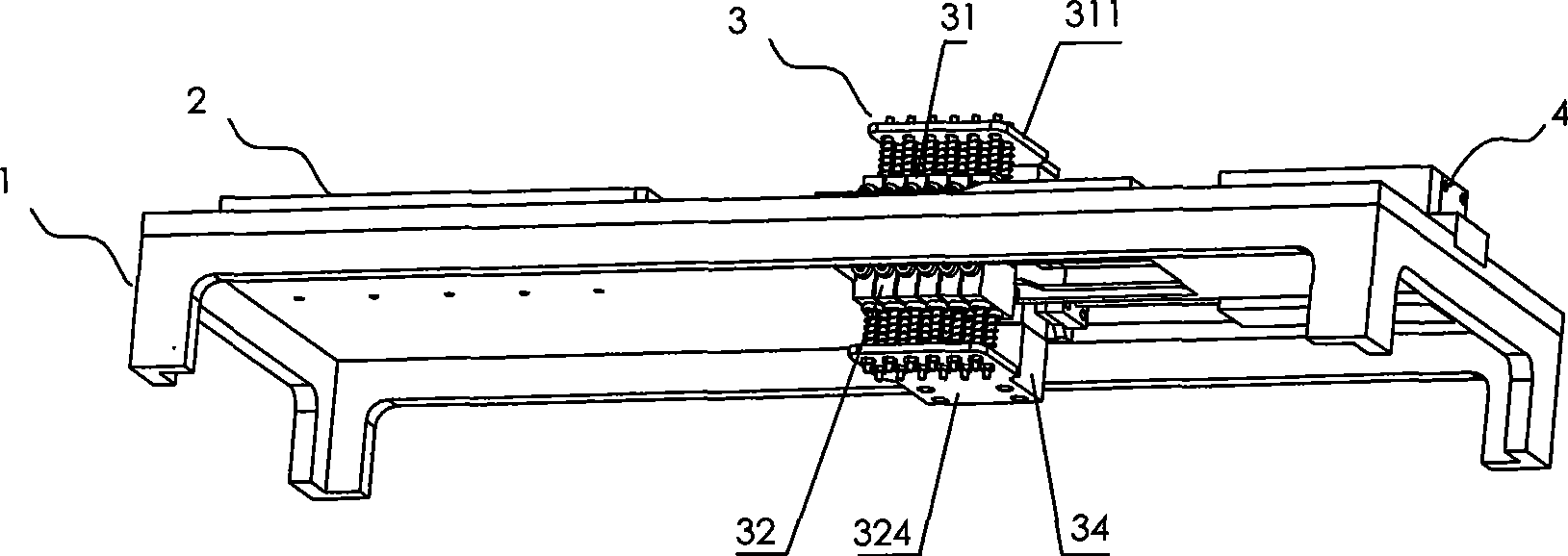

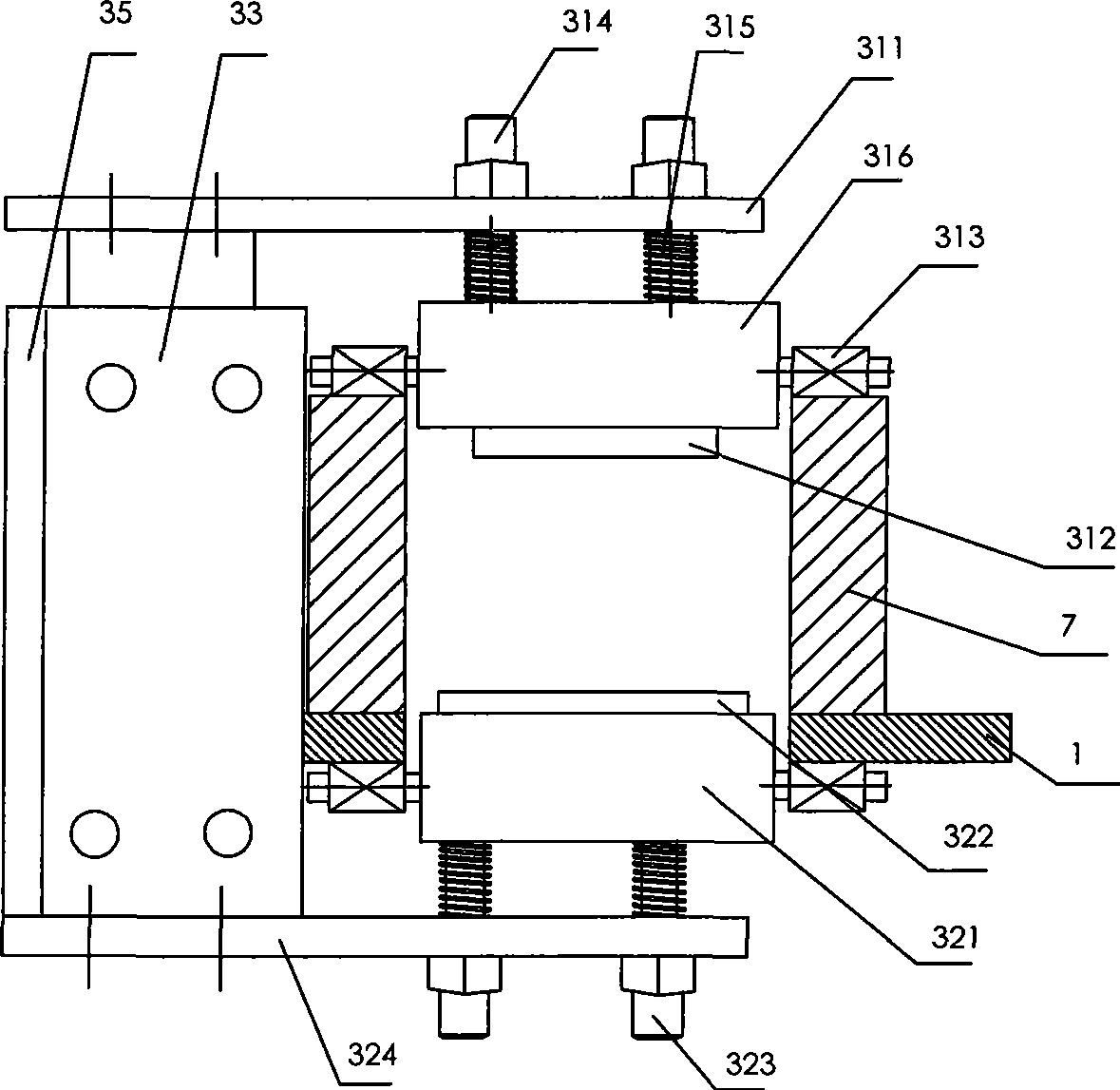

[0047] Such as figure 1 , figure 2 As shown, the present invention provides a fixture that can feed lithium-ion battery cells into an insulating casing, which includes a base 1, and the base 1 is used as a supporting part and a workbench of the entire fixture. On the base 1 , with a cell pushing mechanism 2, a cell clamping mechanism 3, a guide rail 7 and a shell pushing mechanism 4, wherein the cell pushing mechanism 2, the guide rail 7 and the shell pushing mechanism 4 are arranged and fixed on the base 1 in sequence, three They are located on the same straight line, and the cell clamping mechanism 3 is arranged on the guide rail 7 .

[0048] The cell pushing mechanism 2 includes a cell driving device 21, the cell driving device 21 can be an air cylinder, a hydraulic cylinder or a stepping motor, and is fixed on one end of the base 1, and its movable end is connected with the cell pushing plate 22 , The battery pushing plate 22 is used to push the battery, and can push th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com