Apparatus for waxing on groove and tongue side surface on composite floor board

A composite floor and equipment technology, applied to the surface coating liquid device, coating, etc., can solve the problems of slow finishing speed of rolling paint, poor waterproof sealing effect, uneven rolling coating, etc., and achieve low cost and appropriate thickness , the effect of waxing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

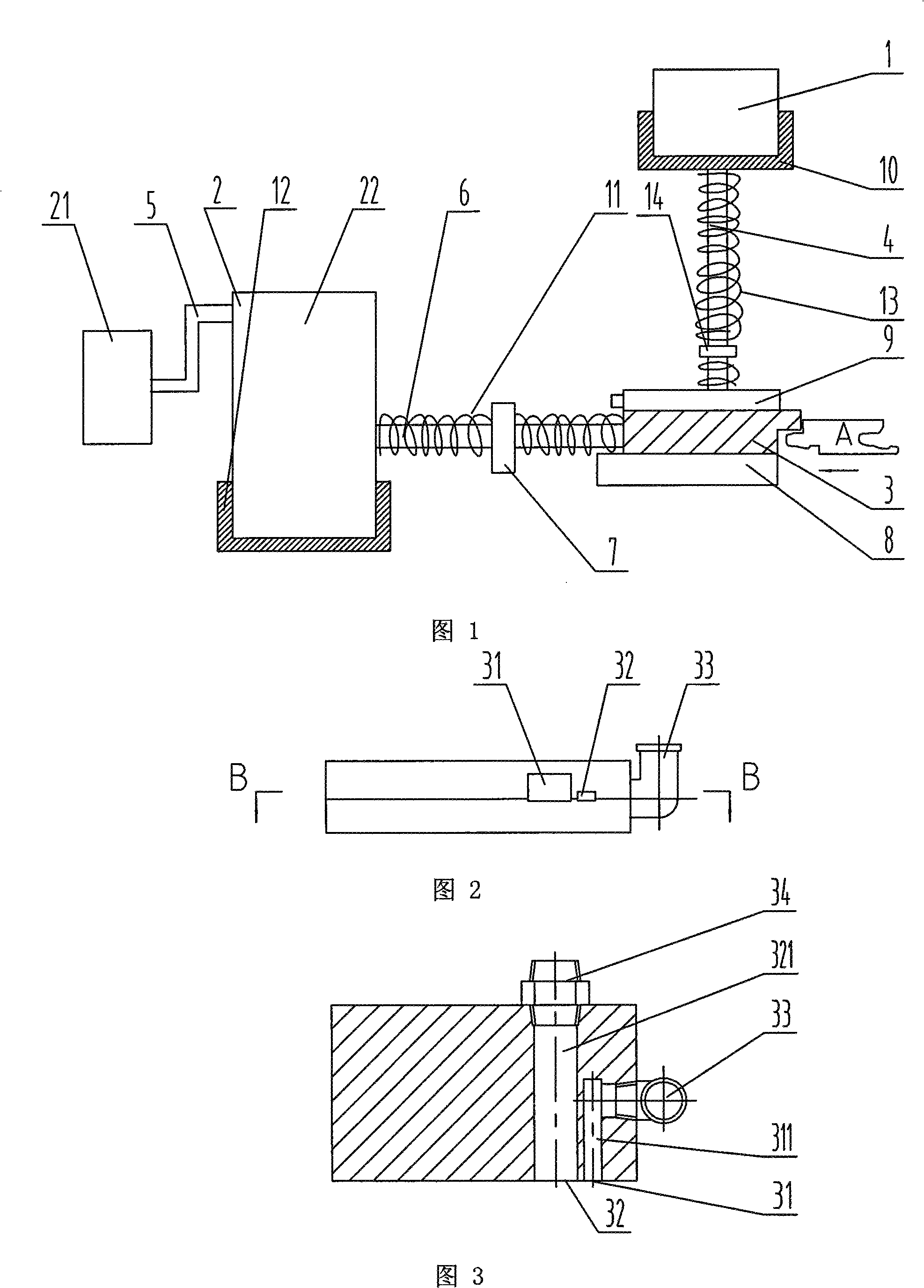

[0020] Referring to Fig. 1~Fig. 3, the present invention comprises charging box 1, recovery device 2 and module 3, and charging box 1 is arranged on the top of module device 3, and the bottom of this charging box 1 is connected with module 3 through conveying pipeline 4, and module 3 Installed on the base 8. The recovery device 2 includes a vacuum pump 21 and a recovery box 22. The vacuum pump 21 is connected to the upper side of the recovery box 22 through the front vacuum pipeline 5, and the bottom of the other side of the recovery box 22 is connected to the front side of the module 3 through the rear vacuum pipeline 6. The module The rear side of 3 is respectively provided with wax injection port 31 and back suction port 32.

[0021] The feeding box 1 is an open feeding box, an electric heating plate 9 is provided above the module 3, an electric heating plate 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com