High-efficiency method for clearing surface defect of continuous casting plate slab

A technology for continuous casting steel and slab, which is applied in the field of efficient cleaning of surface defects of continuous casting steel slabs, can solve the problems of large surface cleaning area of steel billets, affecting production operation rate, and high labor intensity of workers, so as to improve production efficiency and be easy to operate. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

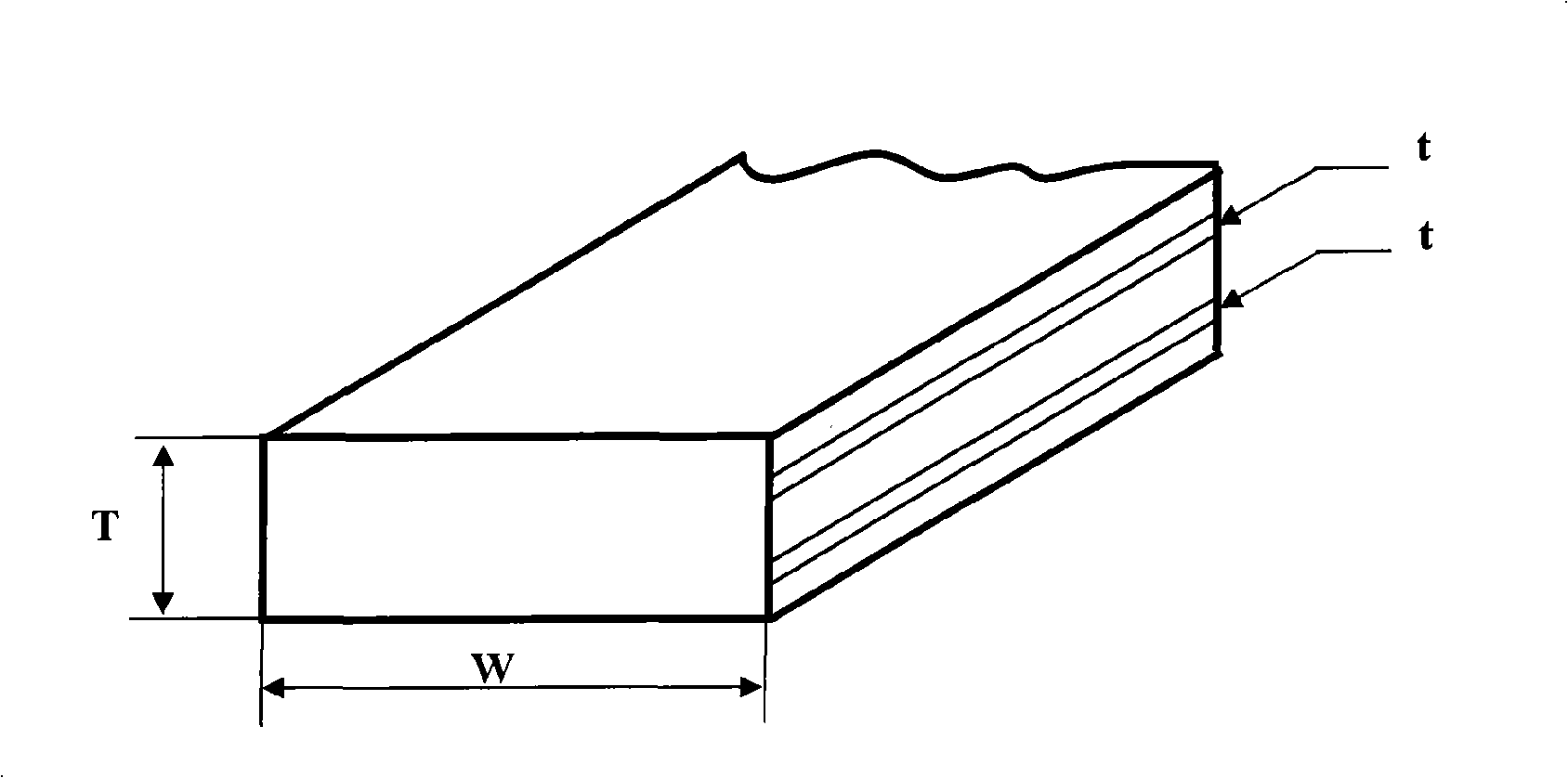

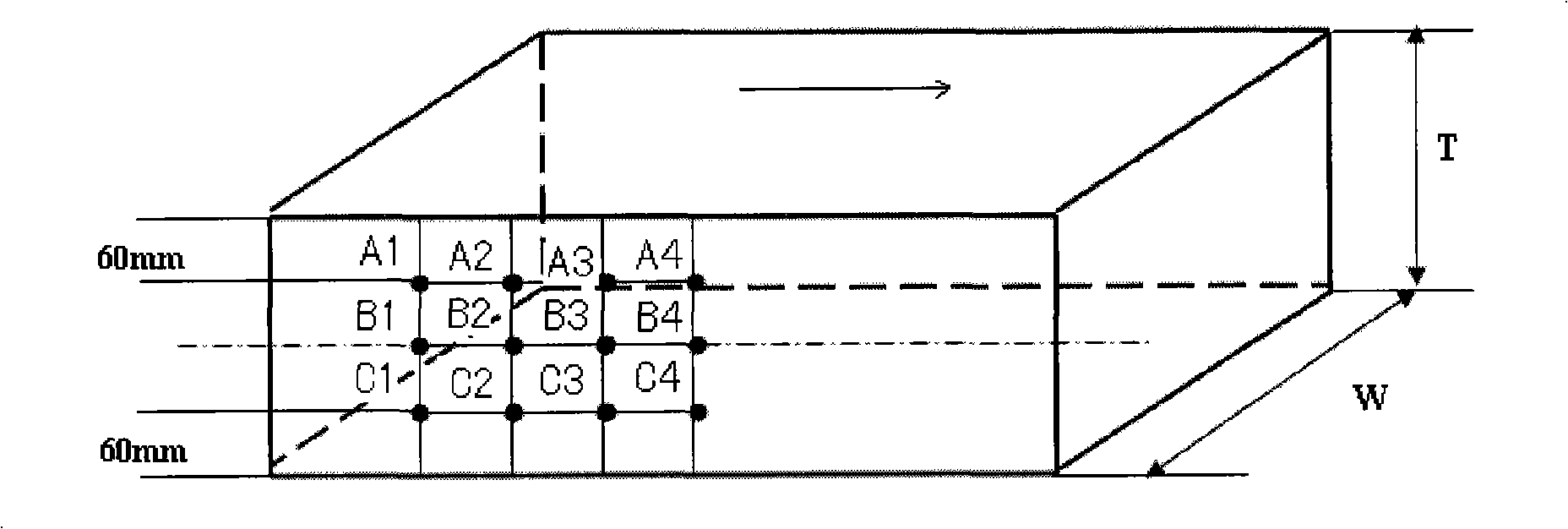

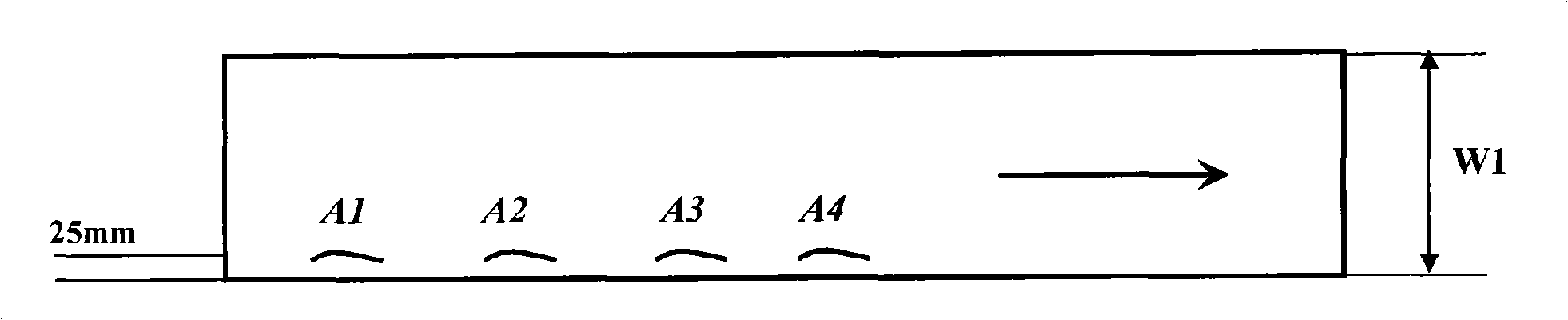

[0044] According to statistics, nearly 10,000 tons of continuous casting slabs, a total of 36 furnaces of steel, are used for hot rolling of low-alloy high-strength steel coils (slabs). The specifications of the continuous casting slab are 230-250mm (thickness) x 1300-2100mm (width) x 6500-9800mm (length). The specifications of the rolled steel coil (open flat plate) are 6-18mm (thickness) x 1200-2100mm (width) x 6000-16000mm (length).

[0045] Statistical results: There are 2700 tons of steel coils rolled without cleaning the surface of the continuous casting slab (open flat plate), 94 steel coils in total. According to statistics, there are 67 steel coils with edge cracks exceeding the standard, and the unqualified amount accounts for 71.27%.

[0046] The continuous casting slab is implemented according to the process of the present invention, totally 7300 tons, 262 steel coils, and the statistical results show that there are no edge cracks.

Embodiment 2

[0048] In November 2007, edge cracks occurred in 12 bridge steel plates rolled by the medium and heavy plate factory, which exceeded the shear width of the edge of the steel plates, resulting in non-standard steel plates that could not be delivered. Count 8 heats of co-casting steel with side cracks, a total of more than 2000 tons of continuous casting slabs, and then carry out artificial flame cleaning on the surface of these unrolled continuous casting slabs according to the process of the present invention. The production statistical results are shown in the following table.

[0049] Statistical results of uncleaned slab and edge cracks after slab cleaning

[0050]

[0051] The above embodiments prove that the present invention is accurate in cleaning the position of the continuous casting slab, and is completely suitable for steel mills to prevent and eliminate edge cracks in the steel plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com