Cyanate resin composition and method of producing the same

A technology of cyanate ester resin and composition, applied in the field of cyanate ester resin composition and preparation thereof, can solve the problems of no production of bisphenol M-type resin, high void ratio of molded products, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0118] Preparation example 1, the preparation of modified cyanate ester resin

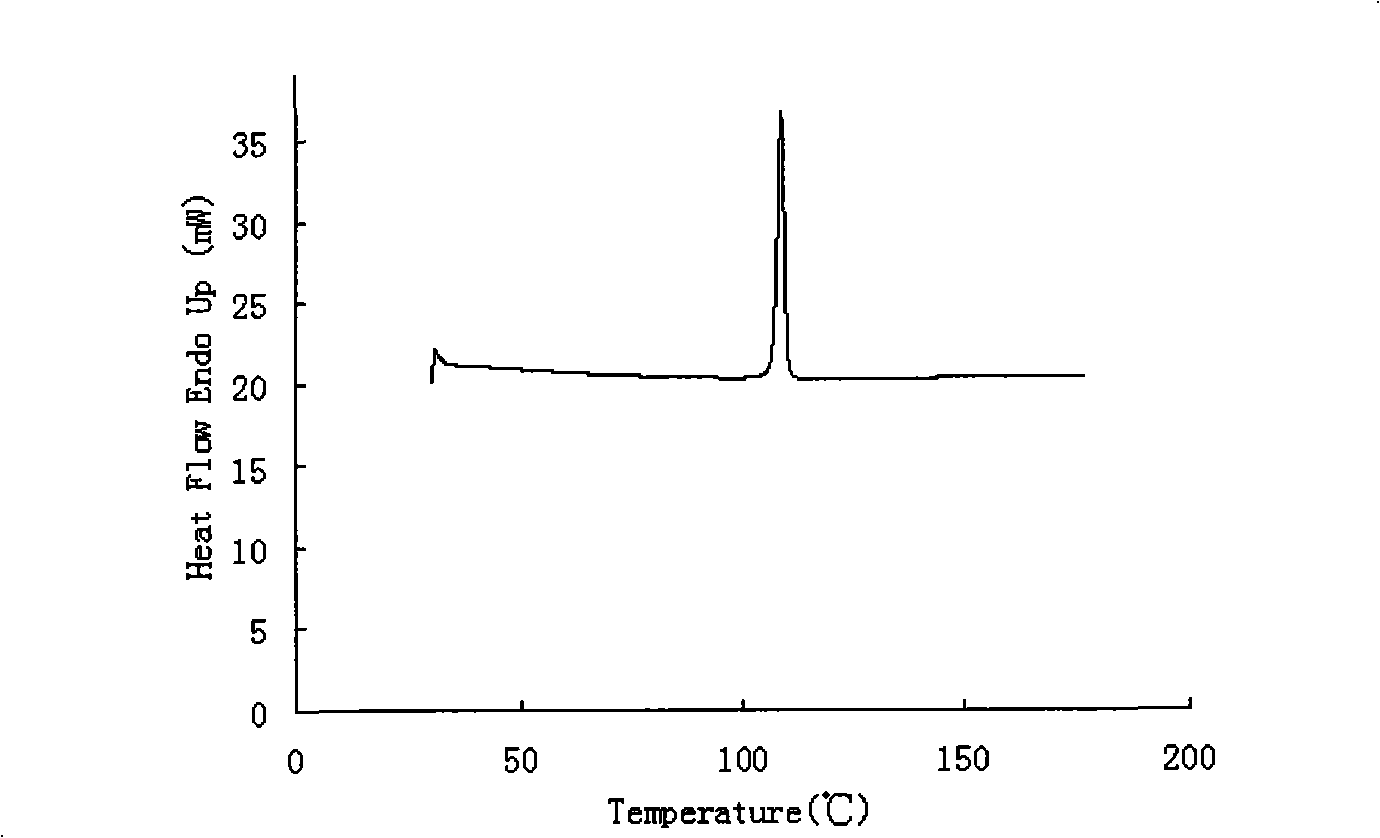

[0119] Add tetramethylbisphenol F-type cyanate into a four-necked bottle, carry out prepolymerization in an oil bath heating environment (specifically, the temperature is 200°C-220°C), and control the end point of prepolymerization with an Abbe refractometer; When the refractive index is 1.576-1.582, add the same amount of modifier into the four-necked bottle and stir evenly to obtain the modified cyanate resin. Pour the mixed resin into a container to cool and set aside.

[0120] Sample example 1, sample preparation

[0121] Lay the quartz cloth in the mold, close the mold, preheat the mold and the modified cyanate ester resin obtained in Preparation Example 1, and then vacuum RTM infusion molding, cool naturally to room temperature after curing, and demould to obtain the product and sample.

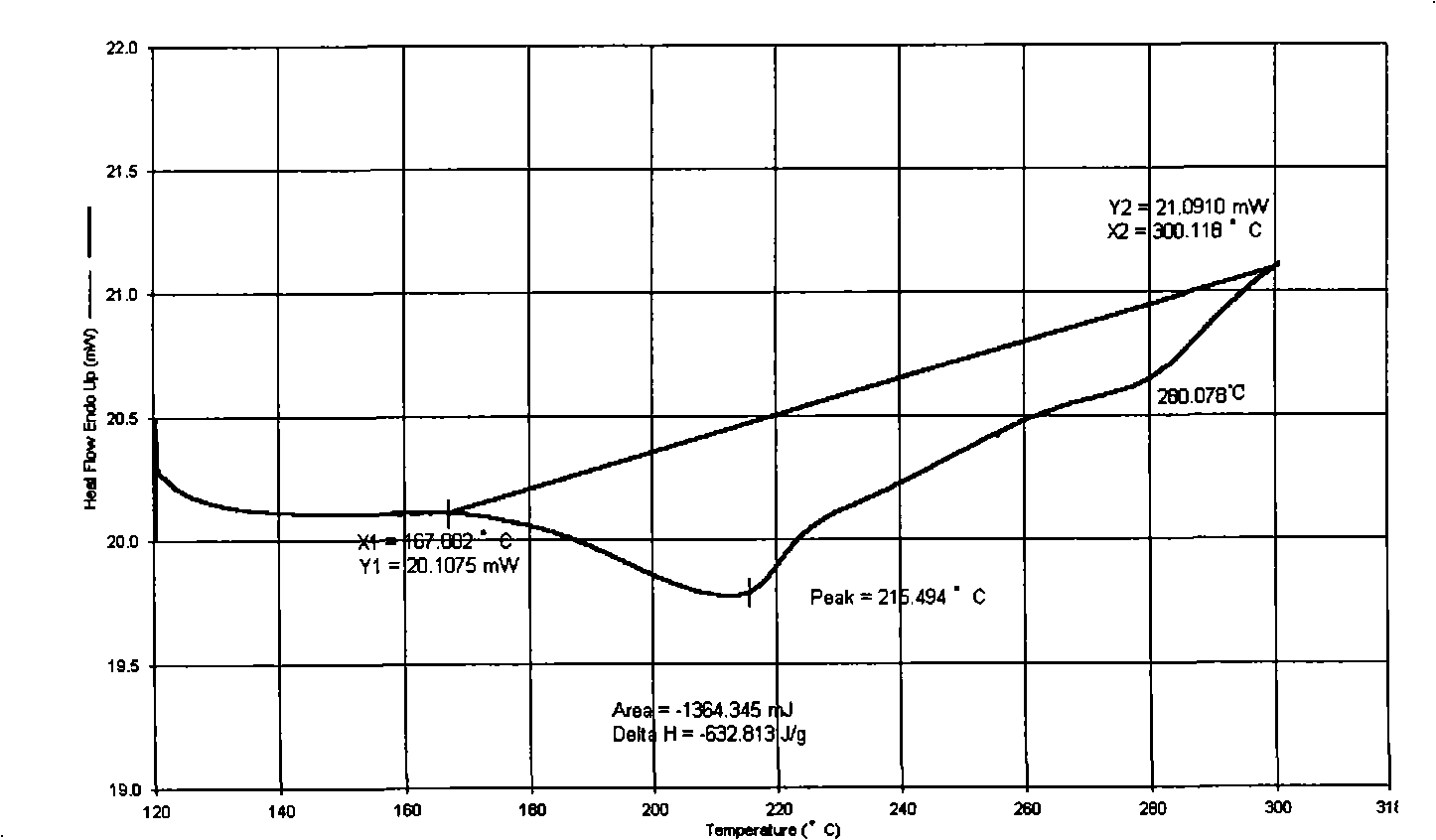

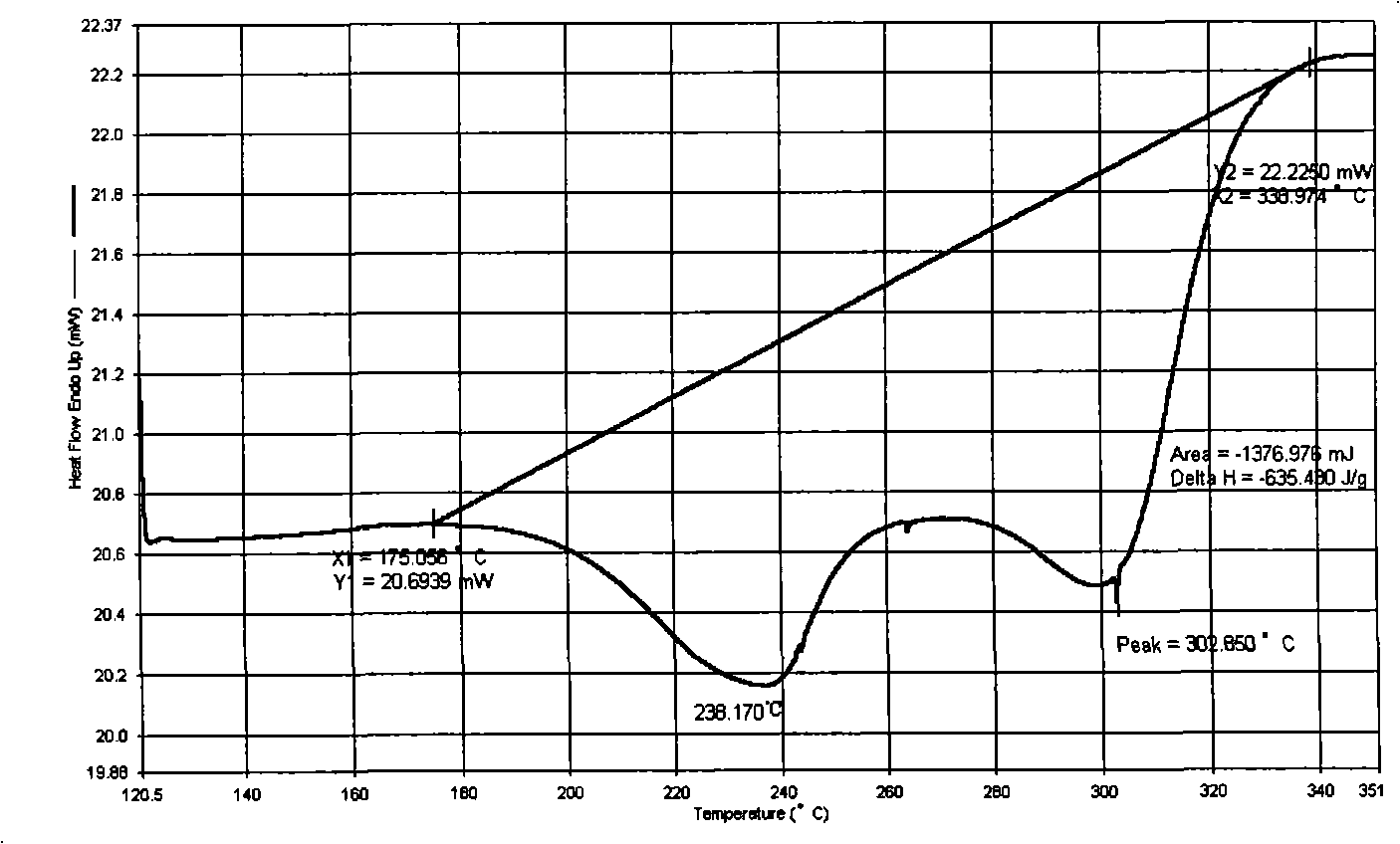

[0122] Performance testing and data processing:

[0123] Determination of viscosity-temperature curve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap