Column type down-hole shut-in well delamination pressure test technique suitable for oil well

A tubular, oil-well technology, applied in wellbore/well components, measurement, earth-moving drilling, etc., to optimize the working system and avoid damaging the original production state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment:

[0028] The string-type downhole shut-in and layered pressure measurement technology applicable to oil wells includes the following steps:

[0029] (1) Firstly, the original well pipe string is lifted out through downhole construction, scraped, and the well is passed through to ensure that the stratified pressure measurement pipe string can be smoothly lowered into the target layer;

[0030] (2) On the basis of 72 hours of production after completion, set the working sequence of the electronically controlled downhole switch. After 72 hours of production after completion, the electronically controlled switch is automatically closed, and the switch control is performed on the corresponding production layer;

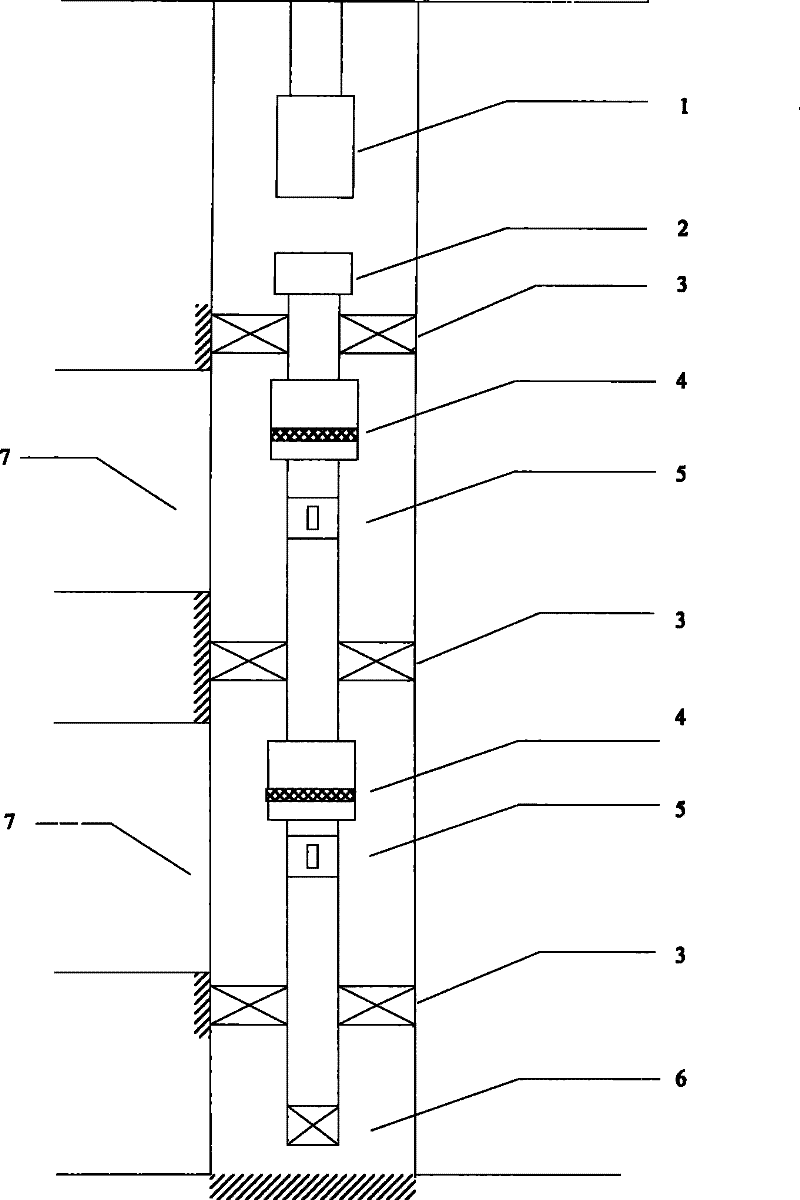

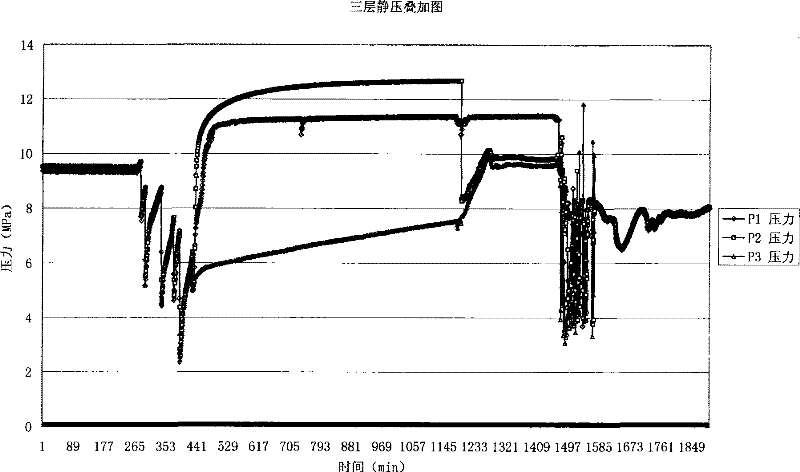

[0031] (3) Run into the distribution string for pressure measurement in layers with a pressure gauge. Packers are used in the production string to isolate the intervals that requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com