Control method and system for shifting peak operation of electric submersible pump oil pumping system

A work control, submersible pump technology, applied in pump control, machine/engine, liquid variable capacity machinery, etc. The effect of reducing operating costs and reducing regulation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

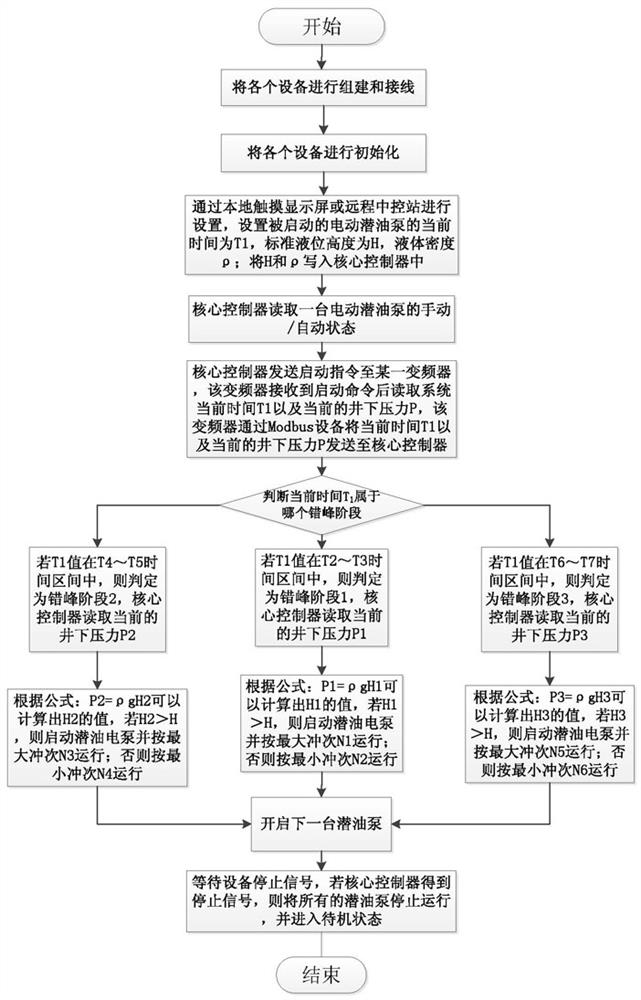

[0025] Embodiment 1: as attached figure 1 As shown, the electric submersible pump pumping system staggered work control method includes the following steps:

[0026] Step 1, according to the electric submersible pump pumping system to complete the construction and wiring of each equipment;

[0027] Step 2, the electric submersible pump pumping system is powered on, and each device is initialized;

[0028] Step 3, set through the local touch screen or remote central control station: set the current time of the started electric submersible pump as T 1 , the standard liquid level height is H, and the liquid density ρ; write H and ρ into the core controller; set the start time of peak shift stage 1 in the core controller as T 2 , the end time is T 3 ; The highest pumping times of the pumping unit at peak shift stage 1 is N 1 , the minimum number of strokes is N 2 ;The start time of the staggered phase 2 is T 4 , the end time is T 5 ; The maximum pumping times of the pumping...

Embodiment 2

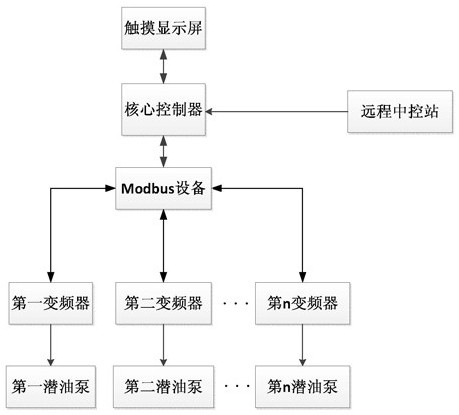

[0038] Embodiment 2: as attached figure 2 As shown, the electric submersible pump pumping system includes a remote central control station, a core controller, a Modbus device, a first frequency converter, a second frequency converter, an nth frequency converter, a first submersible pump, a second submersible pump and an nth A submersible pump, the first submersible pump is connected to the first frequency converter, the second submersible pump is connected to the second frequency converter, the nth submersible pump is connected to the nth frequency converter, the first frequency converter, the second frequency converter and The nth frequency converter is all connected with the Modbus equipment, and the core controller is provided with a serial port and an Ethernet port, and the core controller is connected with the Modbus device through the serial port; the Ethernet port of the core controller is connected with the remote central control through the wireless network TCP / IP co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com