Converter dry-method primary dust removal method based on deep recovery of heat energy

A converter, thermal energy technology, used in the manufacture of converters, climate sustainability, metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

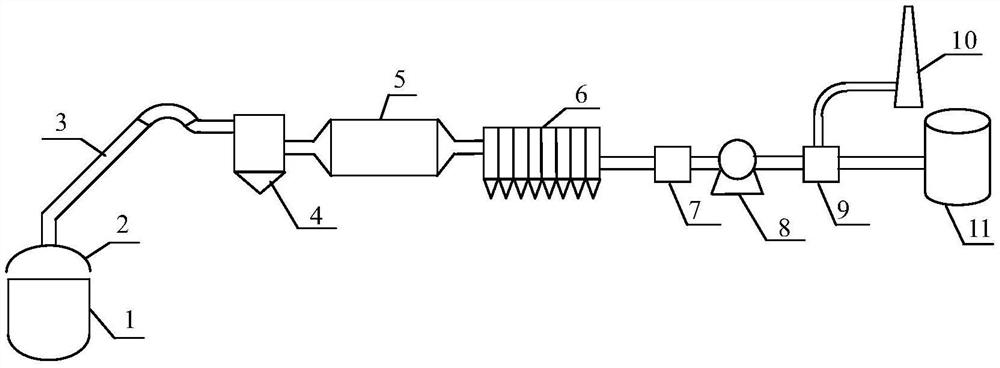

Image

Examples

Embodiment Construction

[0016] At present, there are problems in the primary dust removal of converter dry method. First, the heat energy of the flue gas is seriously wasted. Second, due to the explosion venting problem of the electrostatic precipitator, the overall dust removal index is still difficult to meet the requirements of ultra-low emissions and poses a production safety hazard to steelmaking production. .

[0017] The existing technology partially recovers the heat energy of the primary flue gas produced in the converter smelting process, and uses the vaporization cooling flue to cool the flue gas at a temperature of 1450-1600°C to 800-1050°C, and recovers the flue gas at about 650-800°C Heat energy, the amount of recovered heat energy is less than 50%, and the remaining flue gas heat energy is lost in vain. The remaining heat energy is huge, if it can be recycled, it will produce good social and economic benefits.

[0018] For a long time, due to the lack of systematic and in-depth resear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com