Stress sensitivity test method and device

A technology of stress sensitivity and testing method, applied in measurement devices, analysis of suspensions and porous materials, instruments, etc., can solve the problem of large error in working system optimization and production capacity prediction, overestimation of stress sensitivity, deformation of rock skeleton, etc. The problem of complex particle contact is to optimize the working system and predict the oil and gas production capacity, improve the accuracy, and accurately adjust the permeability variation law.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

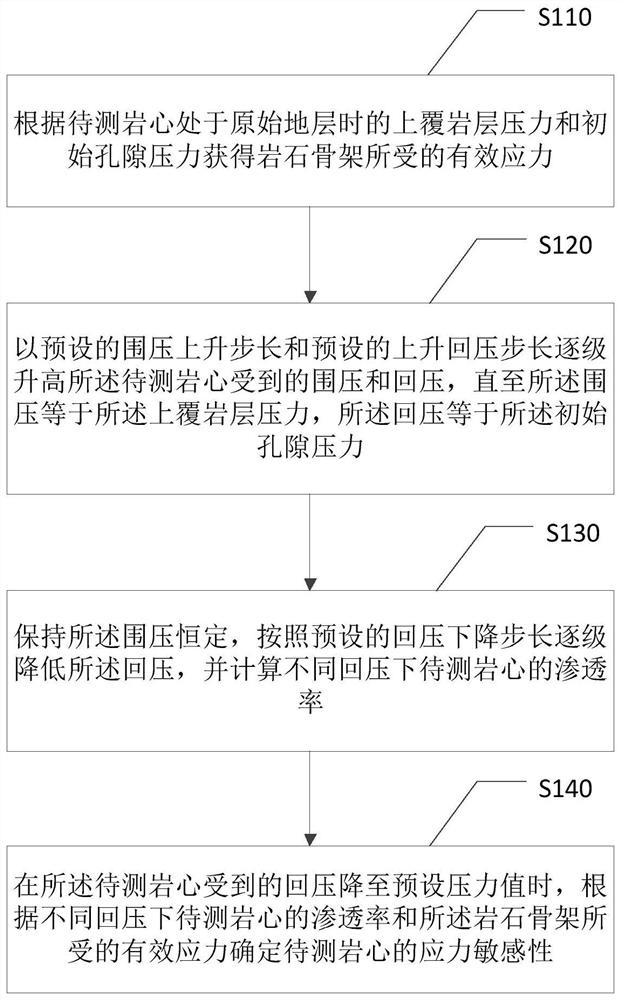

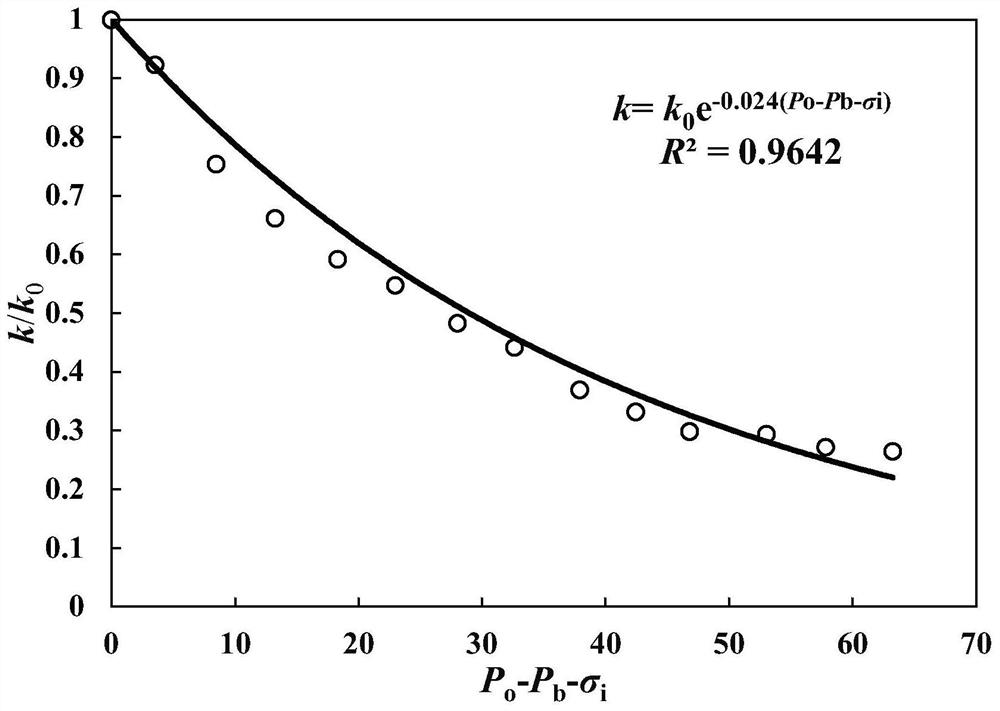

[0056] In this example, the method provided in the example of this specification is applied. First, the core of Weiye 23-1 well (length: 4.976cm, diameter 2.512cm) is calculated. The corresponding overburden pressure is 95MPa, and the initial pore pressure is 75MPa. The effective stress on the rock skeleton under the formation state is 20MPa, the abandonment pressure is 10MPa, and the number of confining pressure and back pressure gradients are both 25, so the confining pressure rise step is 3.8MPa, and the back pressure rise step is 3MPa.

[0057] The specific test steps are as follows:

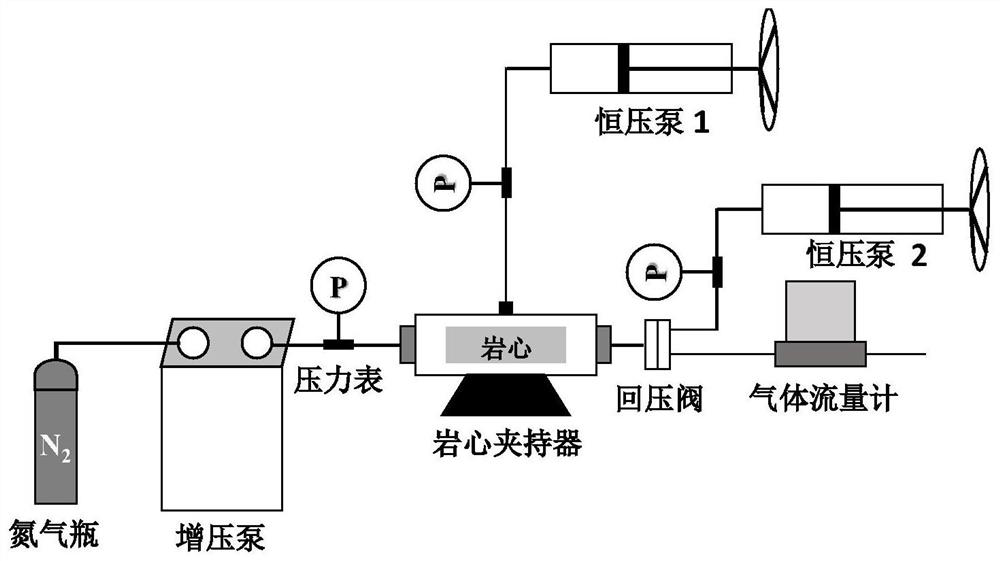

[0058] Step 1: Press figure 2 Connect the experimental process, restore the core to the original formation state, the core confining pressure rise step is 3.8MPa, the back pressure rise step is 3MPa, the confining pressure and back pressure are raised step by step, and the inlet end is injected with constant pressure until it is stable. The next stage of boosting makes the confining pressu...

Embodiment 2

[0069] In this example, the method provided in the example of this manual is used to calculate the core of Yongye 1 well (length: 2.818cm, diameter 2.515cm), the corresponding overburden pressure is 90MPa, and the pore pressure in the initial state is 70MPa. The effective stress on the rock skeleton under the condition is 20MPa, the abandonment pressure is taken as 10MPa, and the number of confining pressure and back pressure gradients are both 20, so the confining pressure rise step is 4.5MPa, and the back pressure rise step is 3.5MPa.

[0070] The specific test steps are as follows:

[0071] Step 1: Press figure 2 Connect the experimental process to restore the core to the original formation state. The core confining pressure rise step is 4.5MPa, and the back pressure rise step is 3.5MPa. The confining pressure and back pressure are raised step by step, and the inlet end is injected with constant pressure until it stabilizes. Carry out the next level of boosting to make th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com