Magnetic field speed reduction type low speed large torque moment permanent-magnet brushless DC motor

A permanent magnet brushless DC, high torque technology, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problems of complex structure, slow system response, etc., achieve flexible control, improve reliability, simplify structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

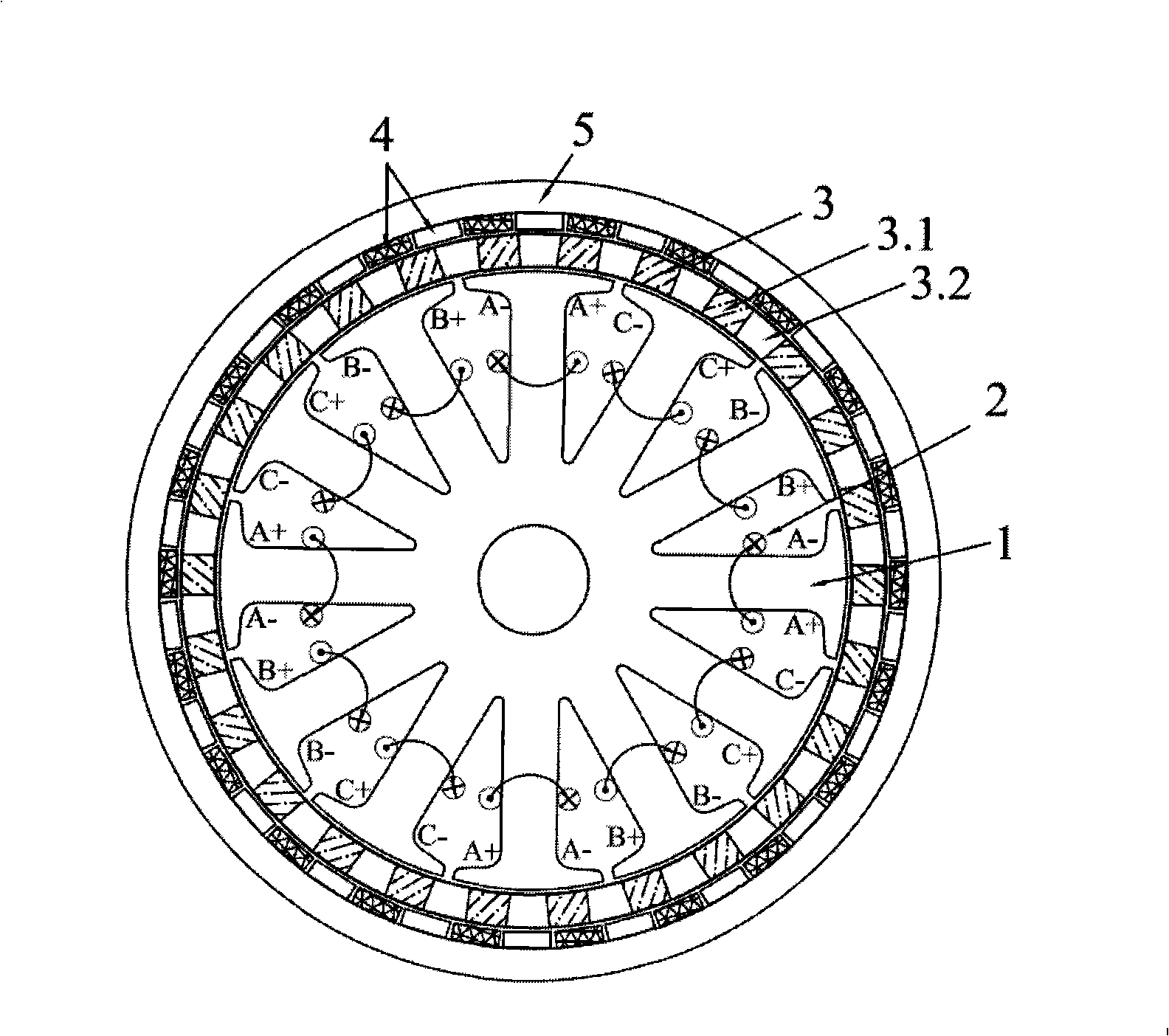

[0014] refer to figure 1 , a magnetic field deceleration type low-speed high-torque permanent magnet brushless DC motor, including an inner stator, an outer stator and a rotor located between the inner and outer stators. The inner stator consists of an inner stator core 1 slotted along the circumferential direction and an electric motor placed in the slot. Pivot winding 2 is formed, the outer stator is composed of annular stator core 5 and N pole and S pole permanent magnets 4 that are alternately arranged on the inner surface of annular stator core 5, and rotor 3 is composed of magnetizers 3.1 and non-magnetizers 3.2 arranged alternately. composition.

[0015] In the illustrated example, the armature winding 2 is a three-phase four-pole concentrated winding, the permanent magnet 4 has 22 pairs of poles, and there are 26 magnetic conductors 3.1 and non-magnetic conductors 3.2 on the rotor, which satisfy the formula: p r =n-p.

[0016] The three-phase windings are connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com