Service component

A technology of service components and snap-fit components, which is applied in the field of service components, can solve the problems of not being able to grasp the fastening bolts and the difficulty of locking service components, and achieve the effect of a simple and robust structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

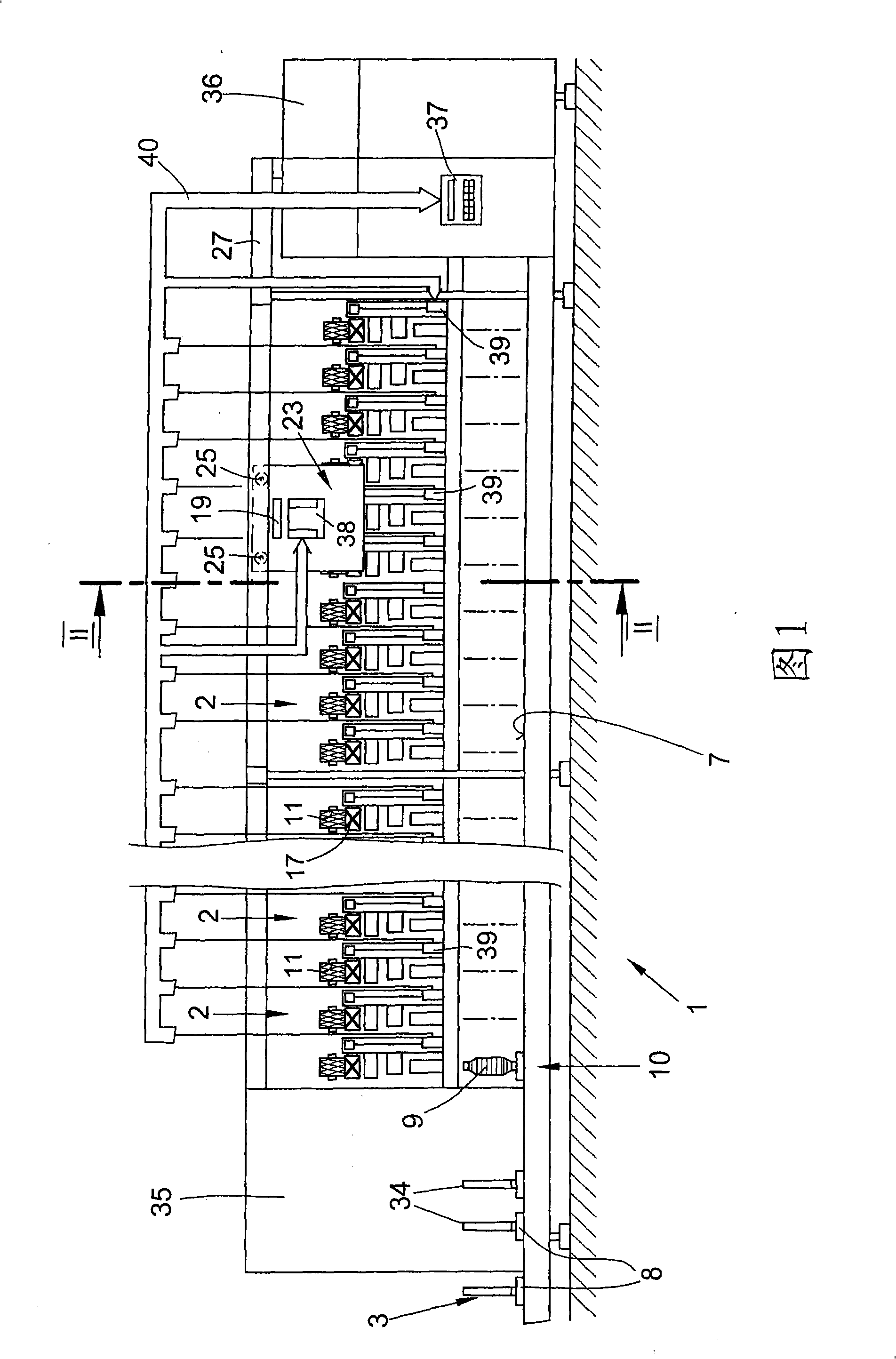

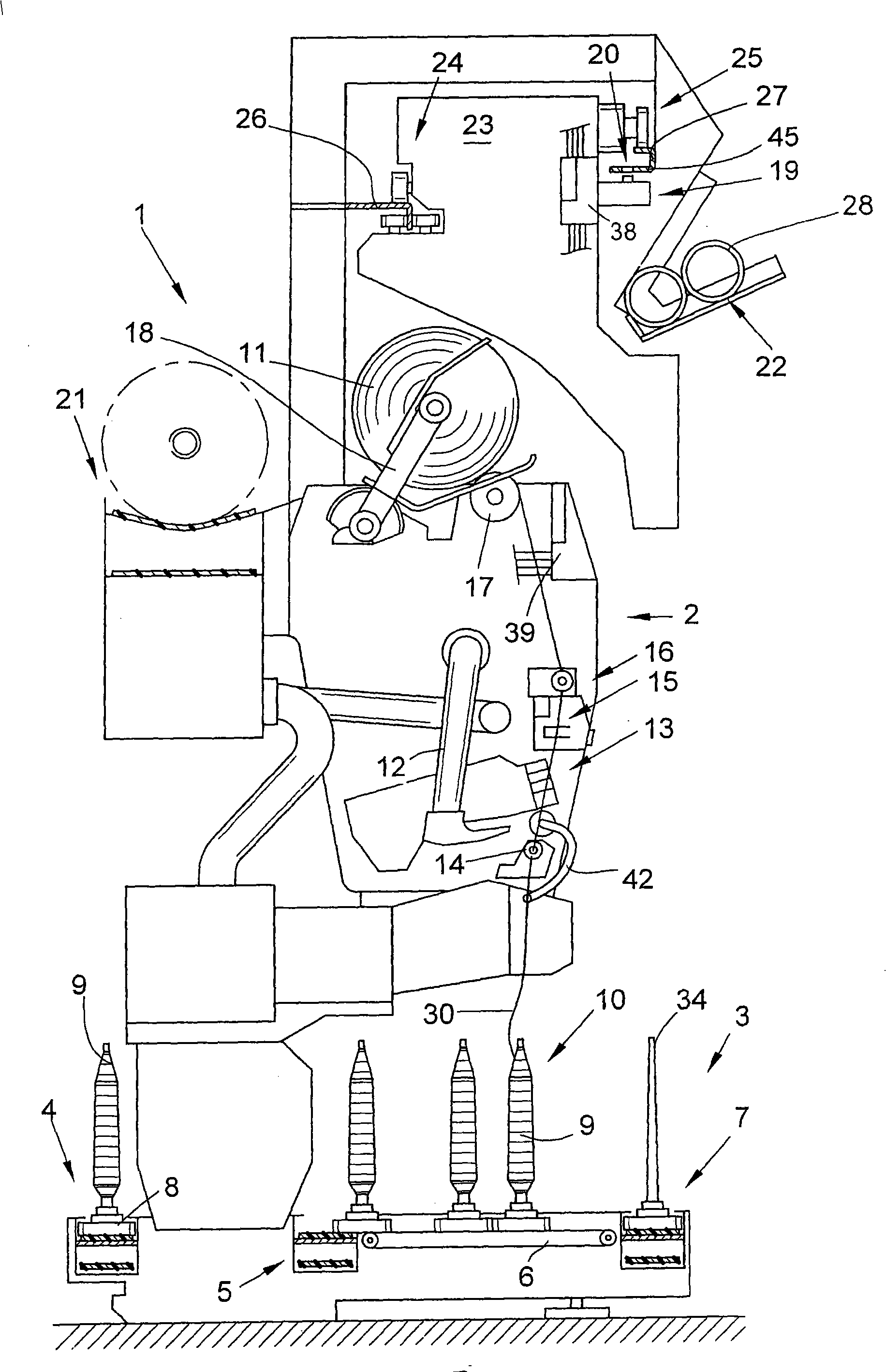

[0016] FIG. 1 schematically shows a front view of a textile machine for producing cross-wound bobbins, in this embodiment an automatic cross-winder 1 . Automatic cross-winders 1 of this type generally have a large number of similar stations 2 between their end frames 35, 36, at which stations the spinning machines have been processed in a ring spinning machine (not shown) connected upstream of the production process. The bobbin 9 produced on (shown in the figure) is rewound to form a high-capacity cross-wound bobbin 11. The finished cross-wound bobbins 11 are conveyed to a cross-wound bobbin conveyor 21 dedicated to the textile machine by means of an automatically operated service unit 23, preferably by means of a so-called cross-wound bobbin doffer, and are then transferred to a A bobbin loading station (not shown) at the head or the like.

[0017] Automatic cross-winders 1 of this type usually also have a logistics mechanism in the form of a bobbin transport system 3 , in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com