Piling machine elevating chain monitoring apparatus and piling machine using the apparatus

A technology for lifting chains and monitoring devices, applied in the field of stacking devices, can solve problems such as failure to replace in time, chain breaking accidents, and inability to fully satisfy operational safety, etc., and achieve the effect of convenient handling and accident avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

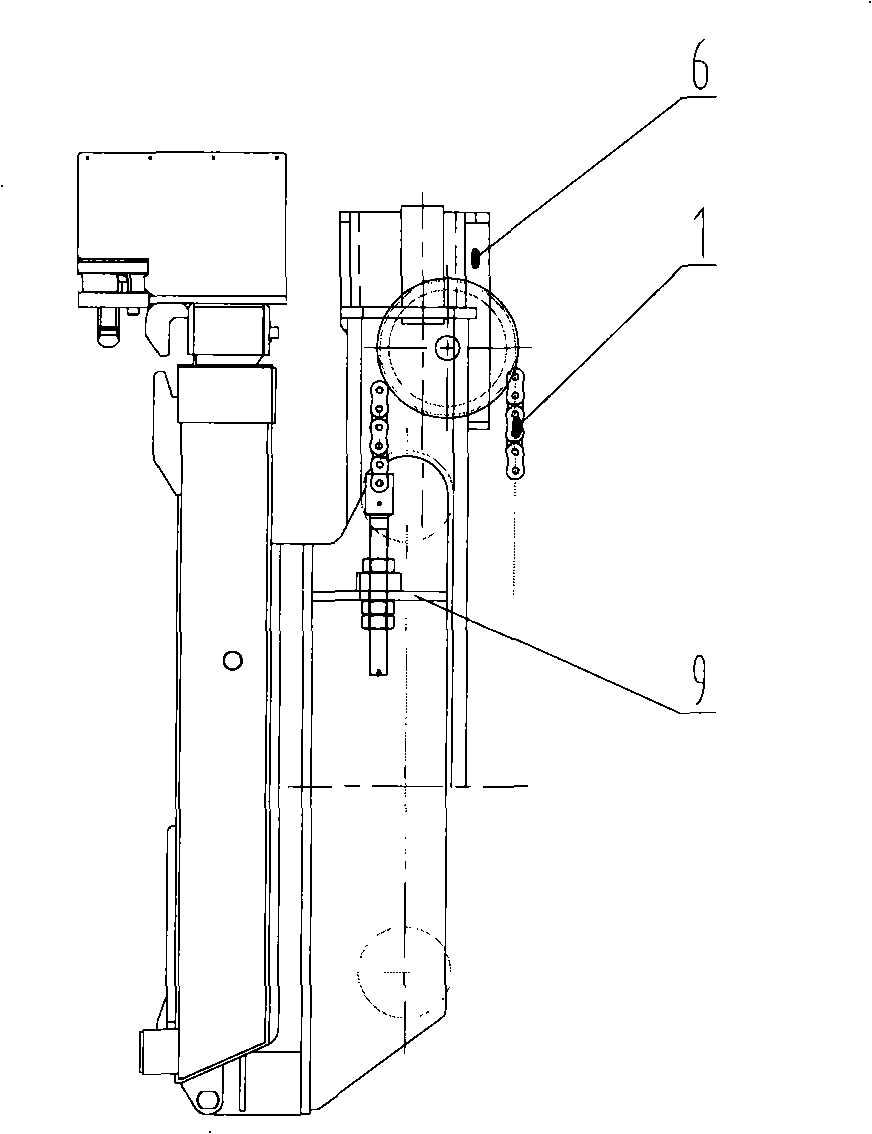

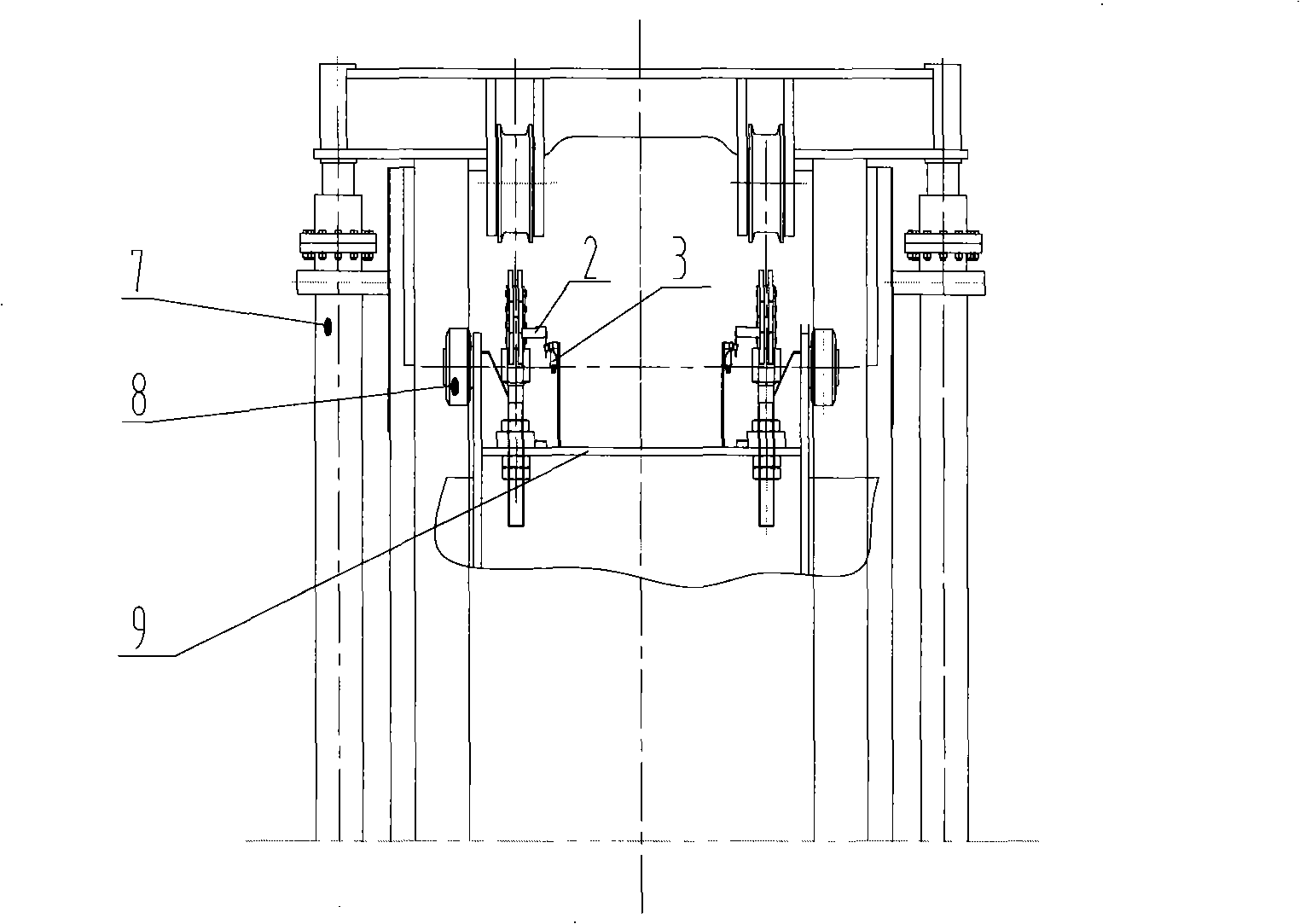

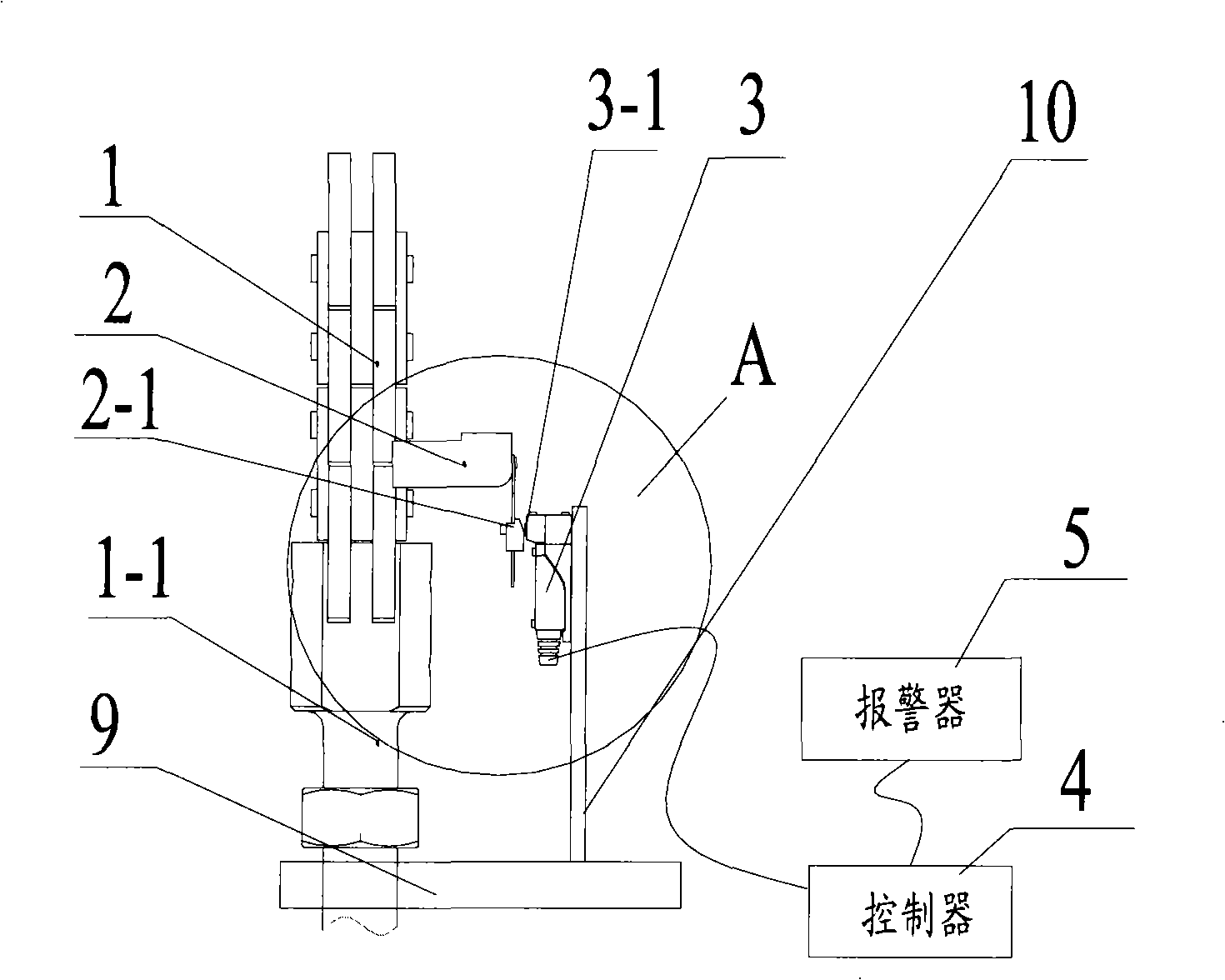

[0030] The basic concept of the present invention is that a trigger is set on the lifting chain, a trigger switch is set on the spreader, and the trigger switch is installed close to the trigger; when the lifting system of the stacker is abnormal, the trigger touches the trigger switch , so that the trigger switch triggers the alarm to alarm due to force.

[0031] The basic principle of the present invention is: the lifting power of the stacker is the oil cylinder, but the direct action mechanism is the chain, and the movement of the chain directly drives the operation of the spreader; at the same time, the chain is a flexible mechanism, and its characteristic is that it must be tensioned when it is stressed. Slack will not force. Therefore, by detecting the movement of the spreader chain in the mast, the operation status of the lift system of the forklift can be monitored in real time; thus, an alarm can be given when the lift system of the forklift is running abnormally to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com