Preparation of siloxane modified polyurethane hydrolysate

A technology of siloxane modification and silane modification, which is applied in the direction of animal fiber, textiles, papermaking, fiber treatment, etc. It can solve the problems of non-compliance with clean production requirements, high baking temperature, hard hand feeling, etc., and achieve improved baking Effect of high temperature, improvement of washing resistance and anti-felting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] At room temperature, add 60 grams of polyethylene glycol (the average number-average molecular mass is 1000) and 4 grams of dimethylol propionic acid into a four-necked bottle, raise the temperature to 120 ° C, and vacuumize for 2 hours under a pressure of 650 mmHg be down to room temperature, calculate the quality of isophorone diisocyanate that needs to be dropped into by a certain molar ratio (-NCO:-OH=2: 1), and add dropwise in the four-necked bottle, under nitrogen protection, heat up to 80° C., add 0.02 g of dibutyltin laurate, continue the reaction for 1 hour, lower the reaction temperature to room temperature, and obtain a prepolymer.

[0028] The ethanol of 20.7 grams is joined in the prepolymer, according to the content of the isocyanate group in the prepolymer measured (measured by the di-n-butylamine-hydrochloric acid titration method), according to a certain molar ratio -NCO:-NH 2 =1:1, after calculating the required mass of γ-aminopropyltriethoxysilane to ...

Embodiment 2

[0031] At room temperature, add 30 grams of polycaprolactone diol (the average number-average molecular weight is 3000) and 4 grams of trimethylolpropane into a four-necked bottle, raise the temperature to 120° C., and vacuumize for 2 hours under a pressure of 600 mmHg. hour; the system was down to room temperature, and the mass of hexamethylene diisocyanate calculated by the molar ratio (-NCO:-OH=1.5:1) was 13.86 grams, which was added dropwise in a four-necked bottle, and under the protection of nitrogen, the temperature was raised to 70° C., add 0.03 g of stannous octoate, continue the reaction for 2 hours, and lower the reaction temperature to room temperature to obtain a prepolymer.

[0032] 10 grams of acetone is added in the prepolymer, dilute, according to the content of the isocyanate group in the prepolymer measured (measured by the di-n-butylamine-hydrochloric acid titration method), according to a certain molar ratio -NCO:-NH 2 =1:2, after calculating the required ...

Embodiment 3

[0035] (1) Anti-felting finish

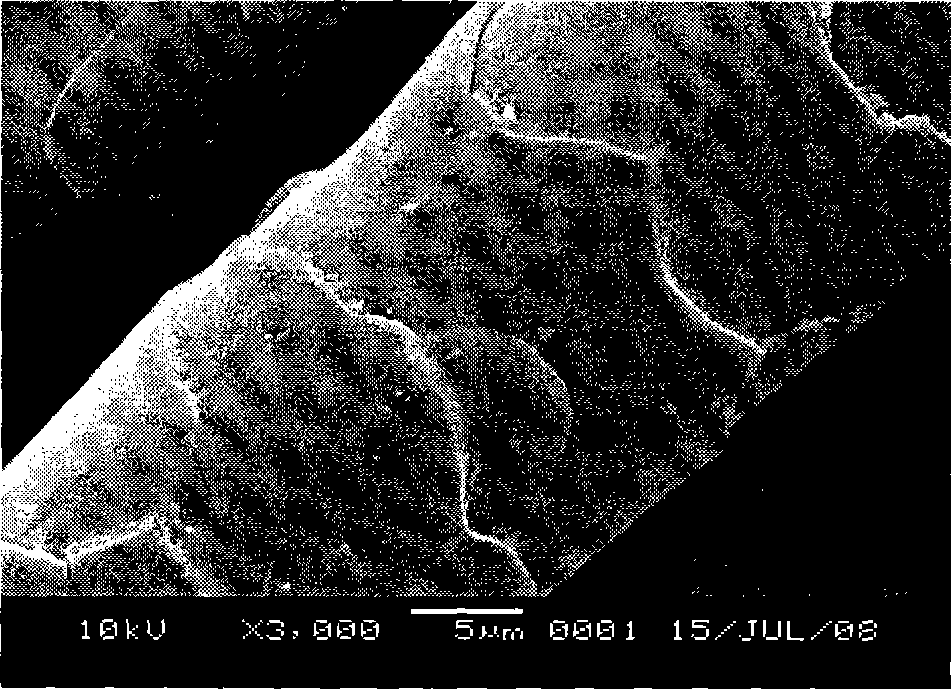

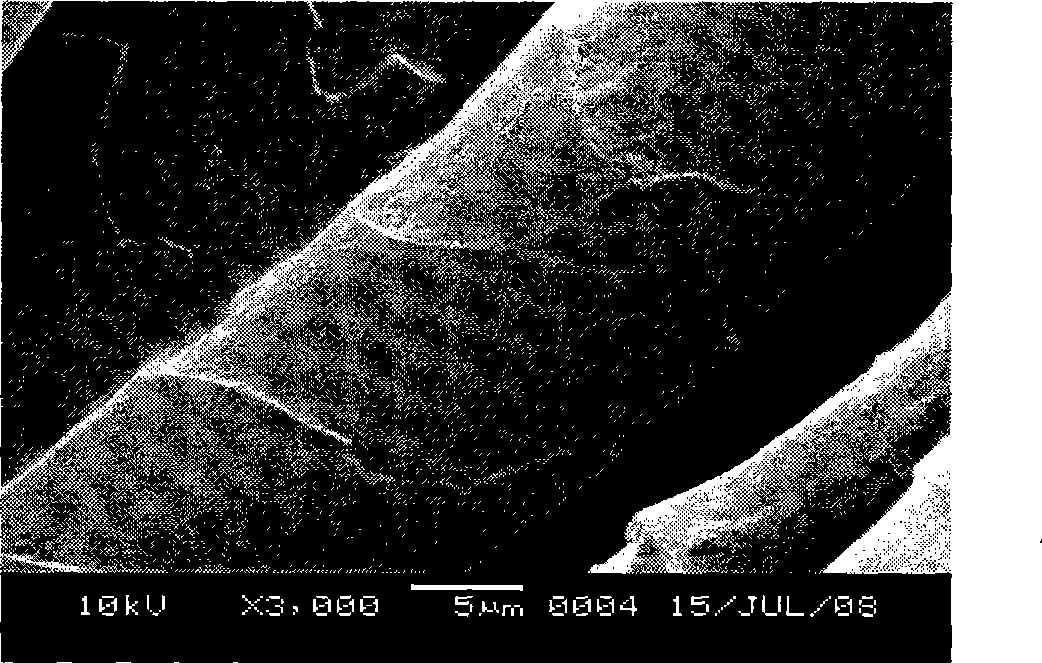

[0036] Four samples of undyed but boiled 100% wool gabardine, (211g / m 2), wherein three samples are dipped and rolled twice in the hydrolyzate in the above-mentioned embodiment 1, and the liquid carrying rate is 70-90%. Machine, Taiwan Labor Tex Co.LTD) in 80 ° C for 3 minutes, 110 ° C, 130 ° C, 150 ° C for 3 minutes each, and naturally dry, while the other sample was not treated. The pictures of the untreated sample and the sample baked at 130°C for 3 minutes are attached figure 1 And attached figure 2 .

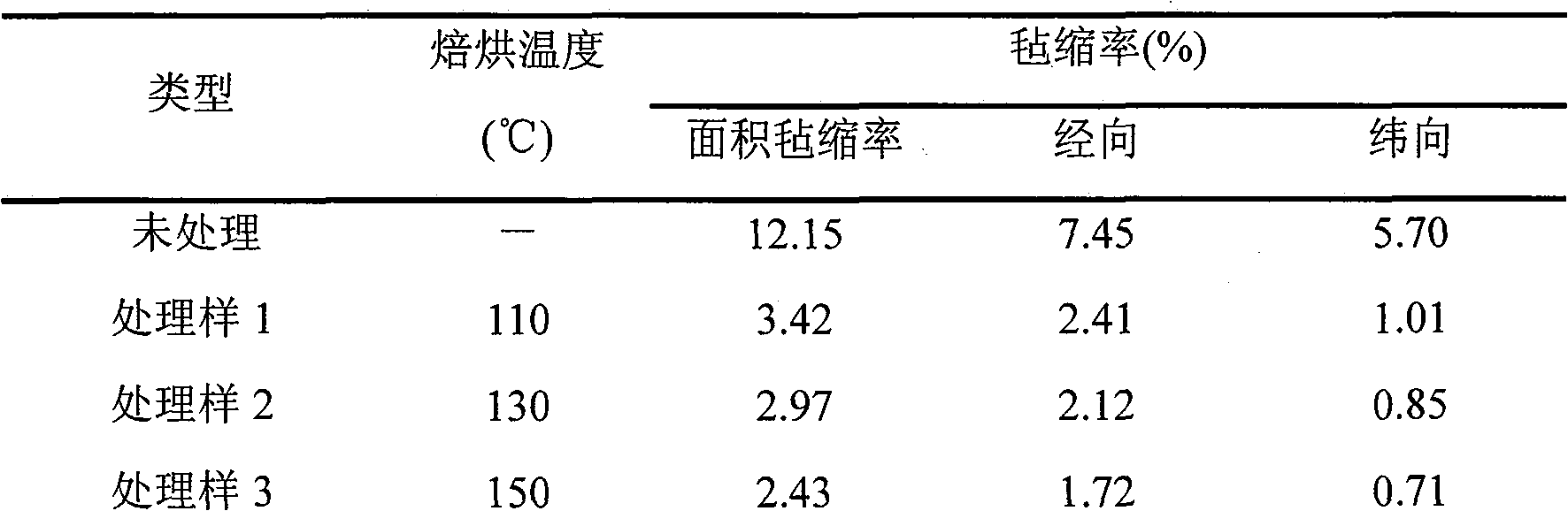

[0037] (2) Anti-felting effect test

[0038] After washing the four samples with reference to the Woolmark TM 31 test standard and method, using a standard washing machine (Wascator FQM71 CLS, EIECTROLUx, program 3*5A wash cycles), the change of felt shrinkage was tested.

[0039] (3) Evaluation of the physical properties of the fabric after finishing

[0040] Four samples were tested for physical properties, including breaking streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com