Energy-saving wall filled with light renewable material

A light-weight material and light-weight technology, applied to walls, building components, buildings, etc., can solve problems such as non-conformity, self-heaviness, and difficulty in general application, and achieve the effects of reducing structural load, reducing structural cost, and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

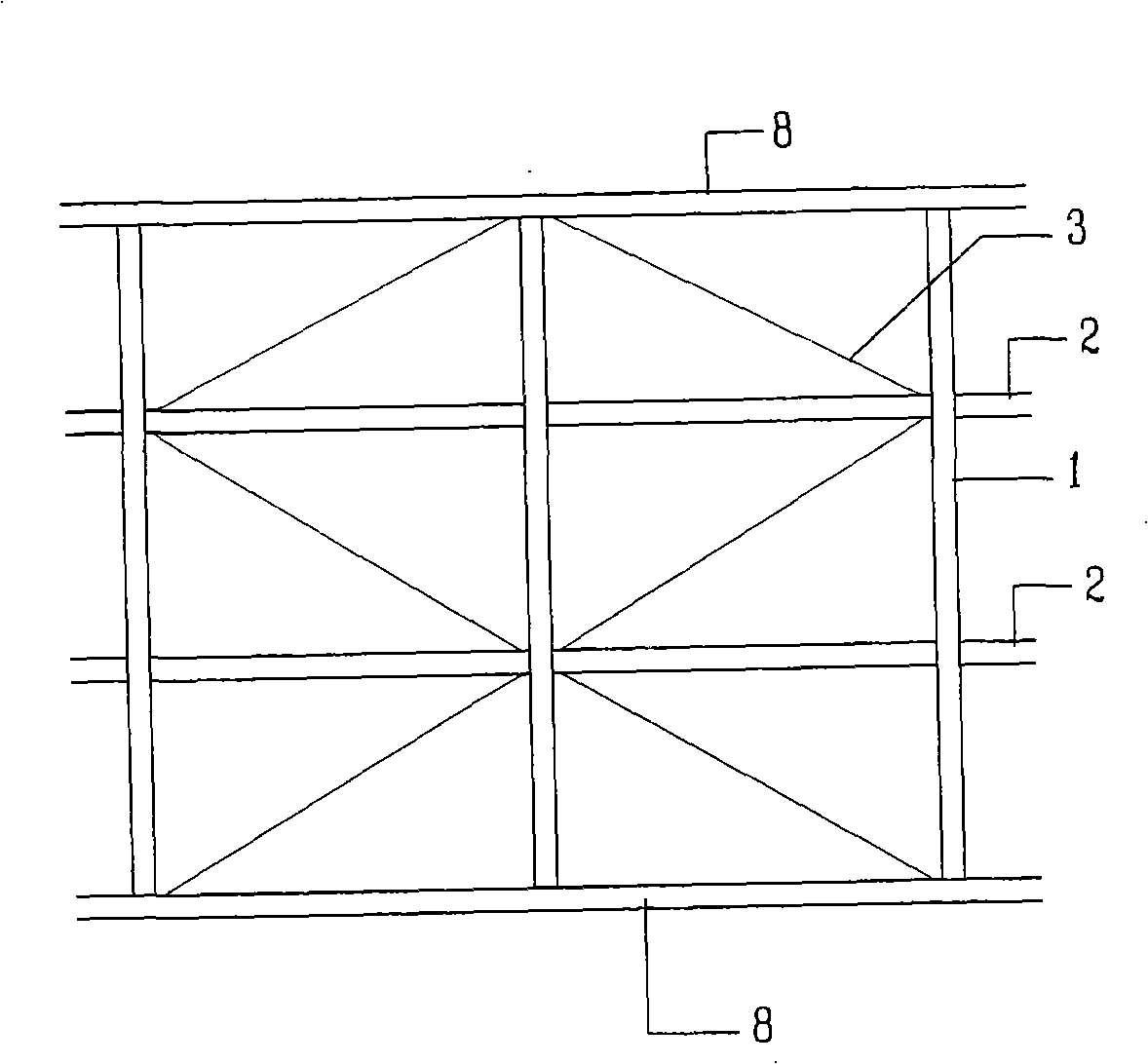

[0015] Such as figure 1 As shown, each group of angle steel columns 1 and angle steel column diagonal stay rods 6 are welded on the ground to form a lattice column, and then the lattice column is installed in place, and the upper and lower ends of the lattice column are fixed on the frame beam 8 . The angle steel horizontal keel 2 is fixed on the outside of the angle steel column 1 with bolts.

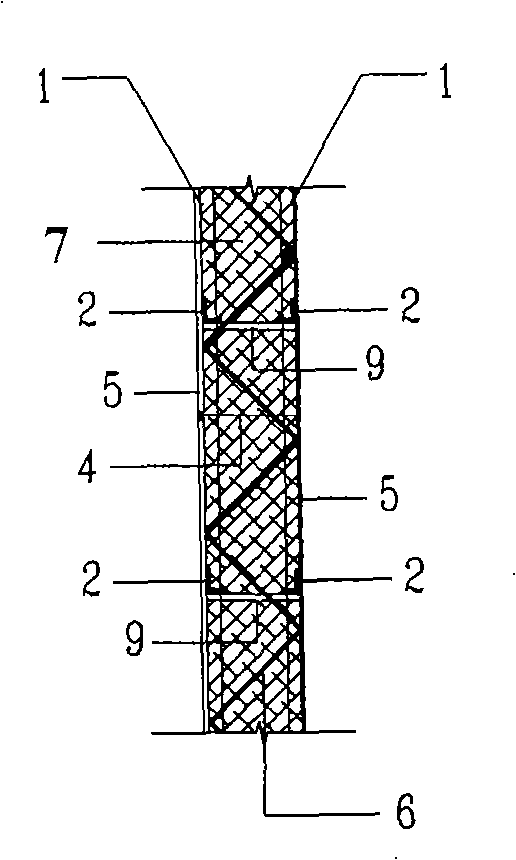

[0016] Such as figure 2 As shown, the cable-stayed reinforcement on the wall facade is welded to the intersection point of the angle steel column 1 and the angle steel horizontal keel 2, and the wall skeleton is completed.

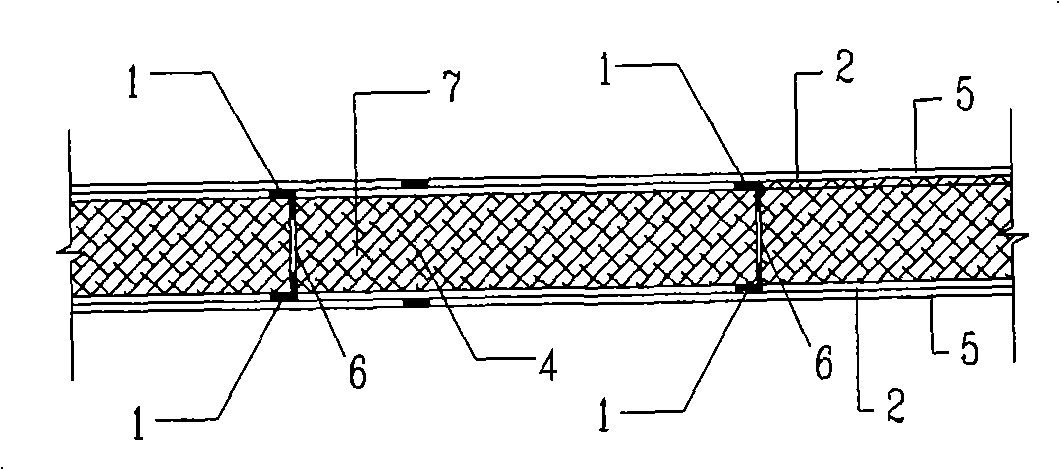

[0017] Such as image 3 As shown, cover both sides of the bottom of the wall skeleton with bamboo nets 5 and fix them with tie wires 4 at a distance of 600, put dry bulk filler 7 between the bamboo nets, and then mix with 5-8% of the wall volume After the quicklime is compacted and filled to the top of the bamboo netting 5, the horizontal wooden pressing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com