Movable contact assembly and switch using the same

A technology of moving contacts and switches, applied in the field of movable contact bodies, can solve the problem that the display part 8C cannot be illuminated brightly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

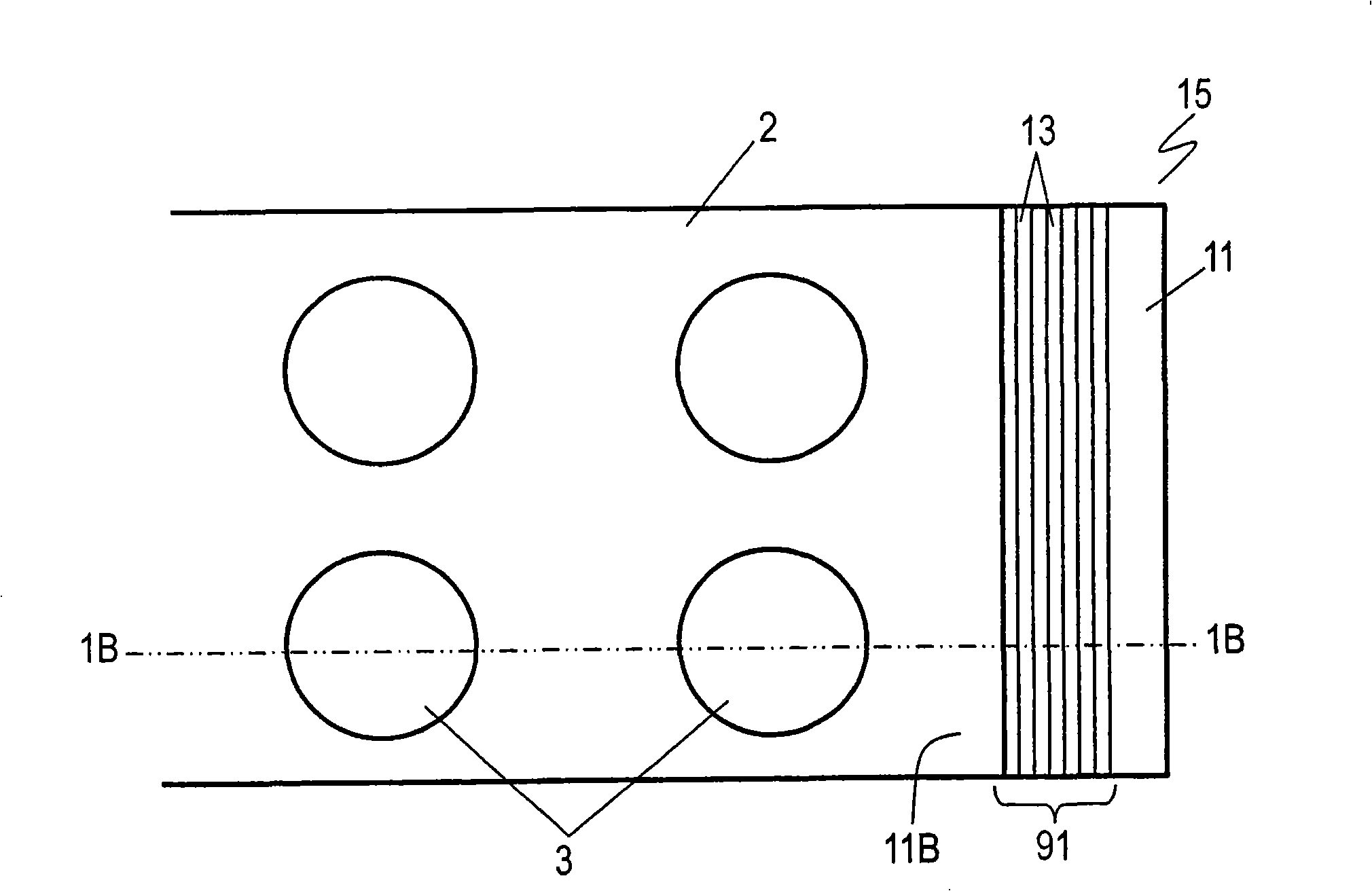

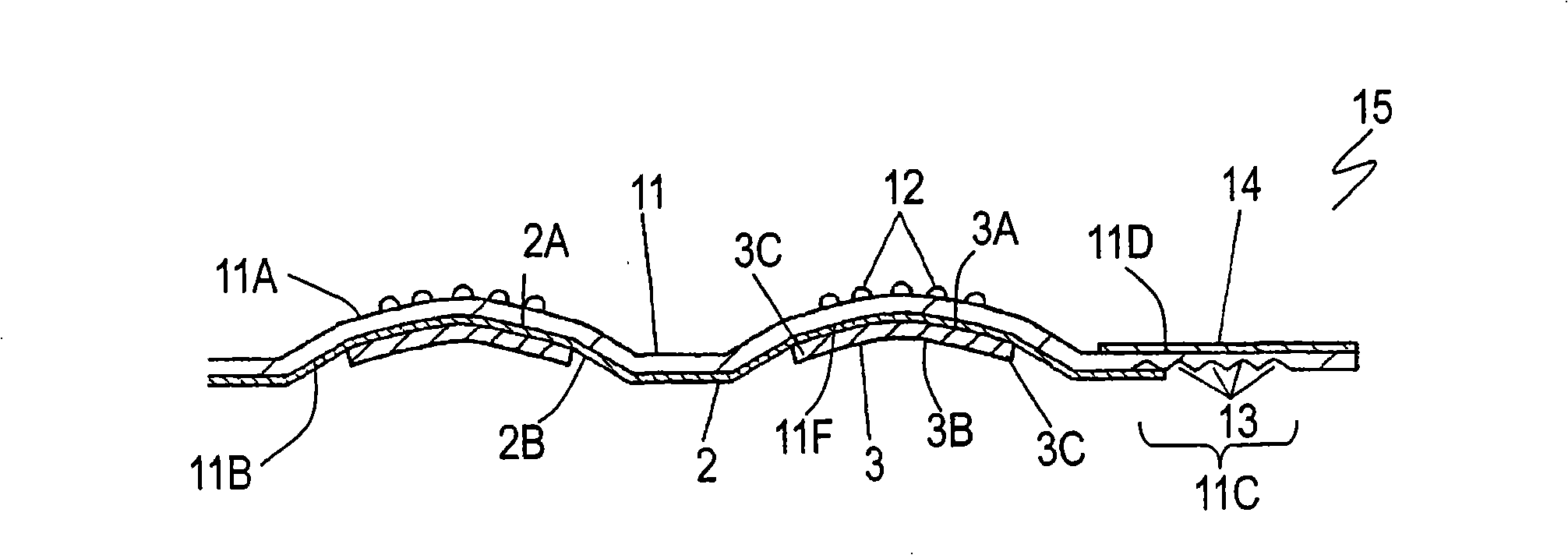

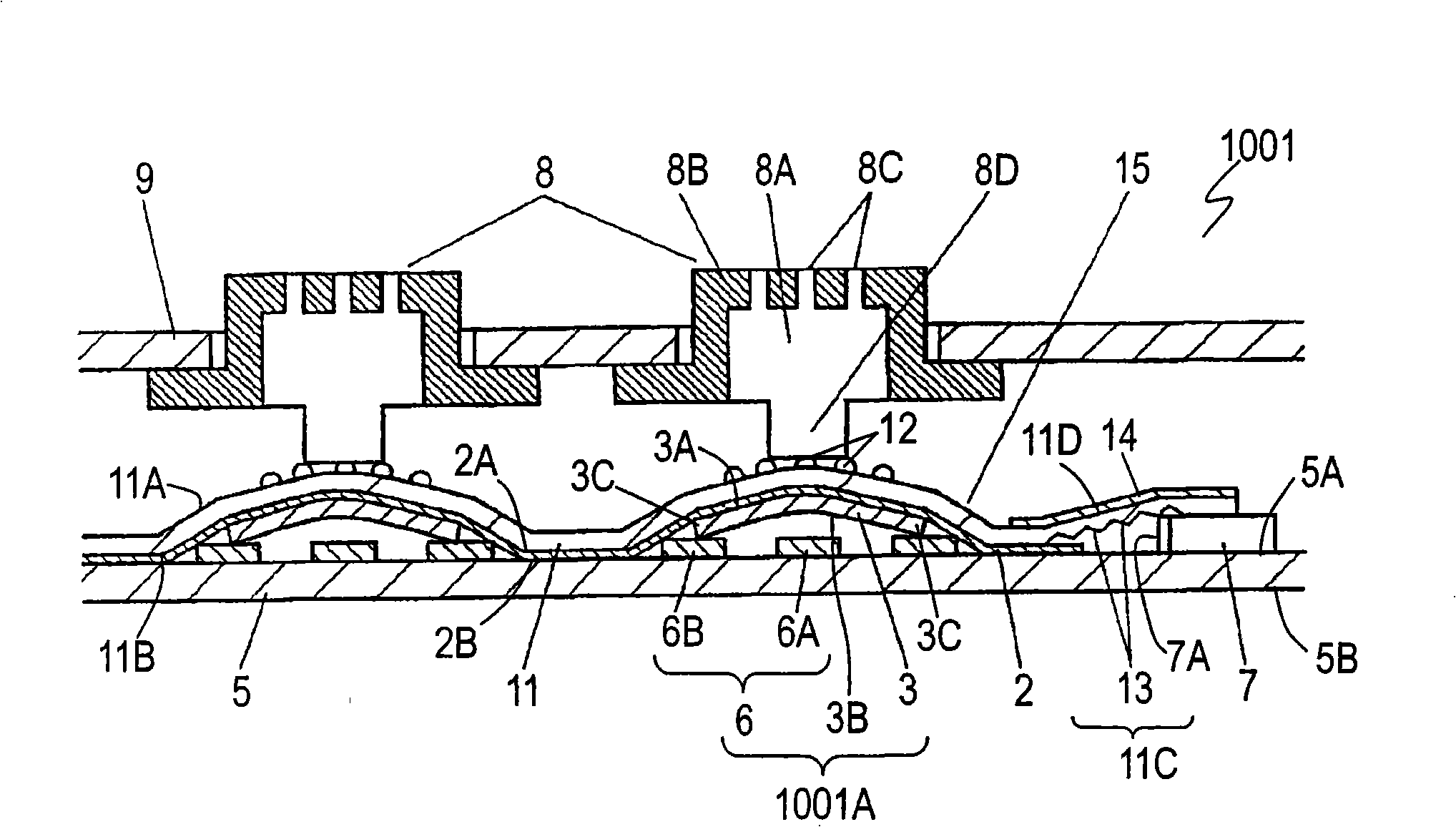

[0028] Figure 1A It is a bottom view of movable contact body 15 according to the embodiment of the present invention. Figure 1B yes Figure 1A A sectional view of the movable contact body 15 taken along line 1B-1B is shown. The light guide sheet 11 is in the form of a film and is made of a flexible light-transmitting member such as polyethylene terephthalate, polycarbonate, polyurethane, or silicone. The light guide sheet 11 has an upper surface 11A and a lower surface 11B opposite to the upper surface 11A. The light guide sheet 11 has a plurality of diffuser portions 12 having a dot shape attached to the upper surface 11A. The diffuser 12 is composed of a transparent resin such as acrylic resin and a white pigment such as titanium oxide dispersed in the transparent resin. The cover sheet 2 is attached to the lower surface 11B of the light guide sheet 11 with an adhesive agent at predetermined positions on the outer periphery of the upper surface 2A of the film-shaped co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com