Driving device of stepping motor

A technology of stepping motor and driving device, applied in the direction of motor generator control, electrical components, control system, etc., can solve the problems of excessive heating of the coil, inability to reduce the proportion of current flowing, and inability to sufficiently reduce power consumption, etc. Achieving the effect of reducing power consumption and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] (Overall structure of the driving device of the stepping motor of the present invention)

[0033] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

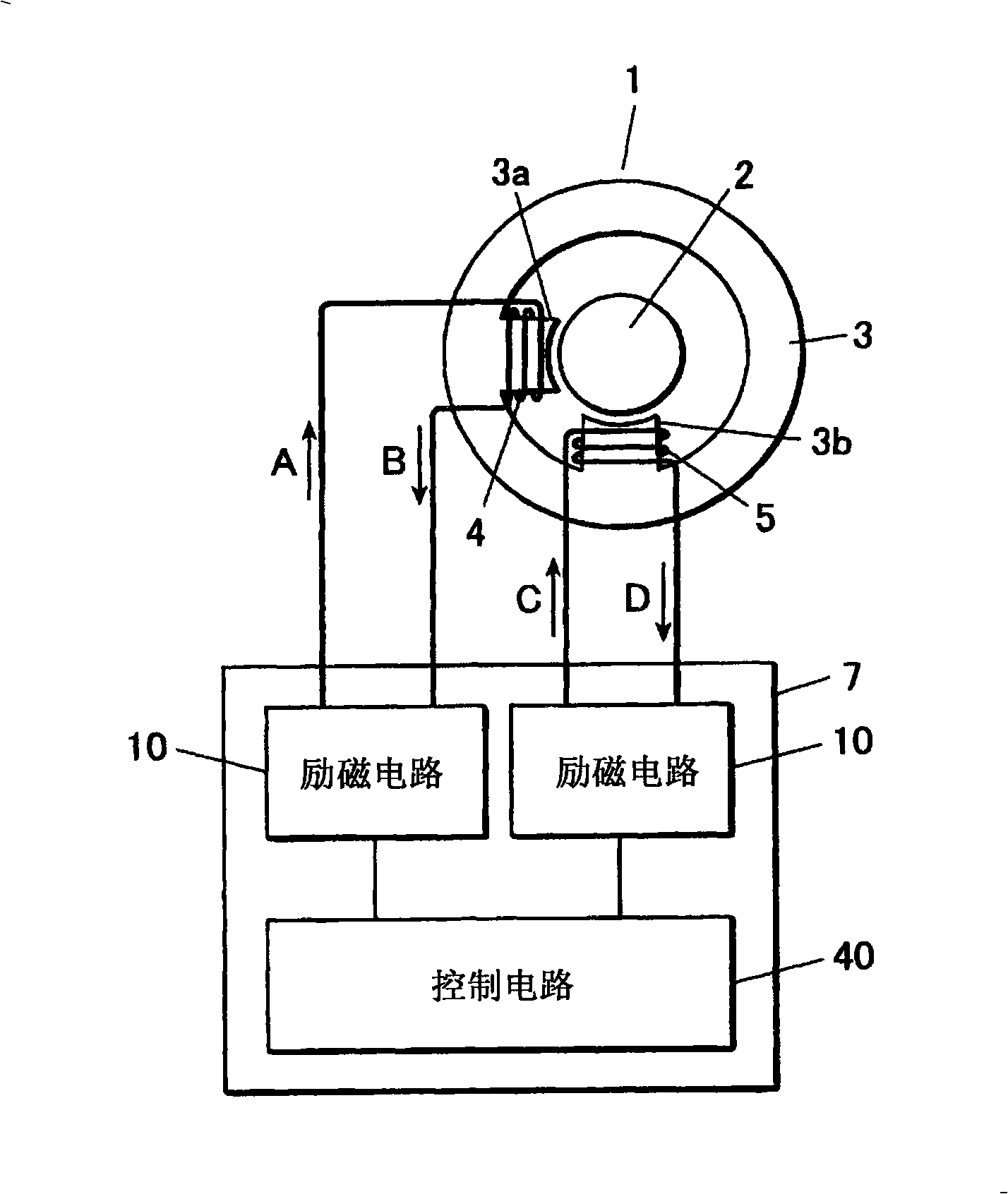

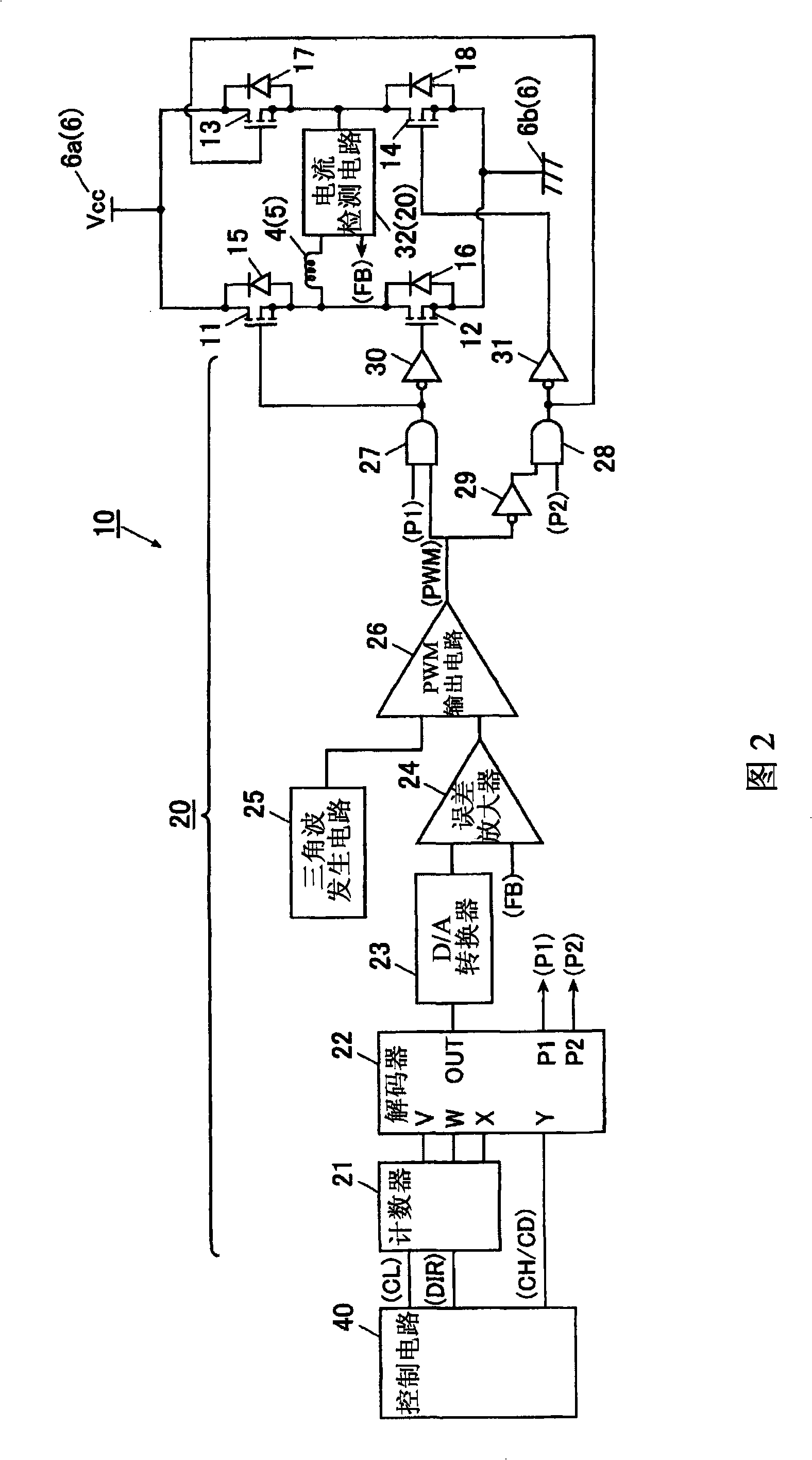

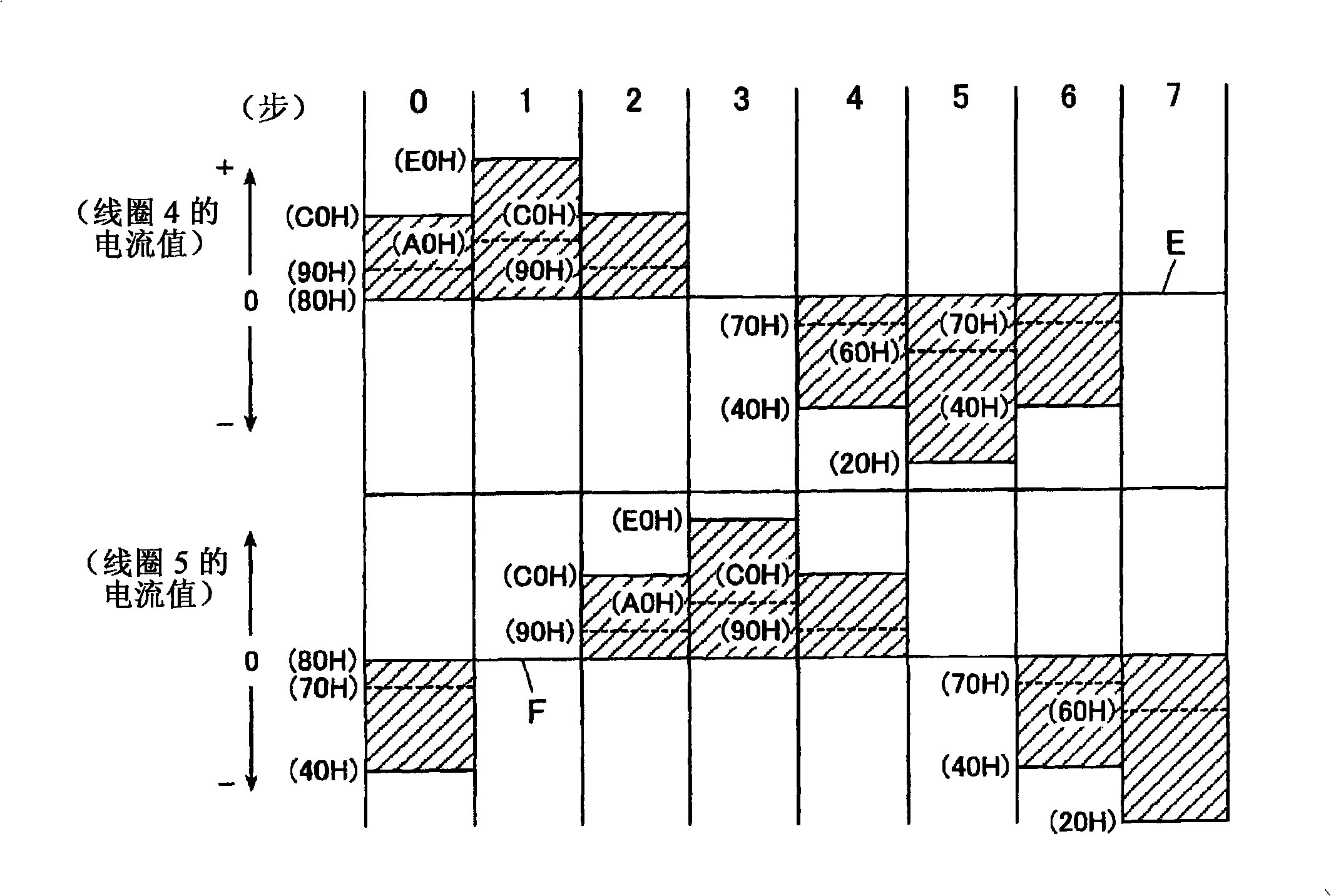

[0034] The driving device 7 of the stepping motor of the present invention is the driving device of the stepping motor of the sewing machine, and it has: FET (field effect transistor) 11~14, and it is arranged on the coil 4,5 of stepping motor 1 (refer to figure 1 ) between the power supply and function as a switching element (refer to FIG. 2 ); and the drive circuit 20 controls the current flowing in the coils 4 and 5 to a constant current by controlling the on / off of the FETs 11-14 ( Refer to Figure 2).

[0035] (stepping motor)

[0036] exist figure 1 Among them, the stepping motor 1 has: a cylindrical rotor 2, which is connected to the rotating shaft of the stepping motor so as to be rotatable; a cylindrical stator 3, which is arranged around the rotor 2;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com