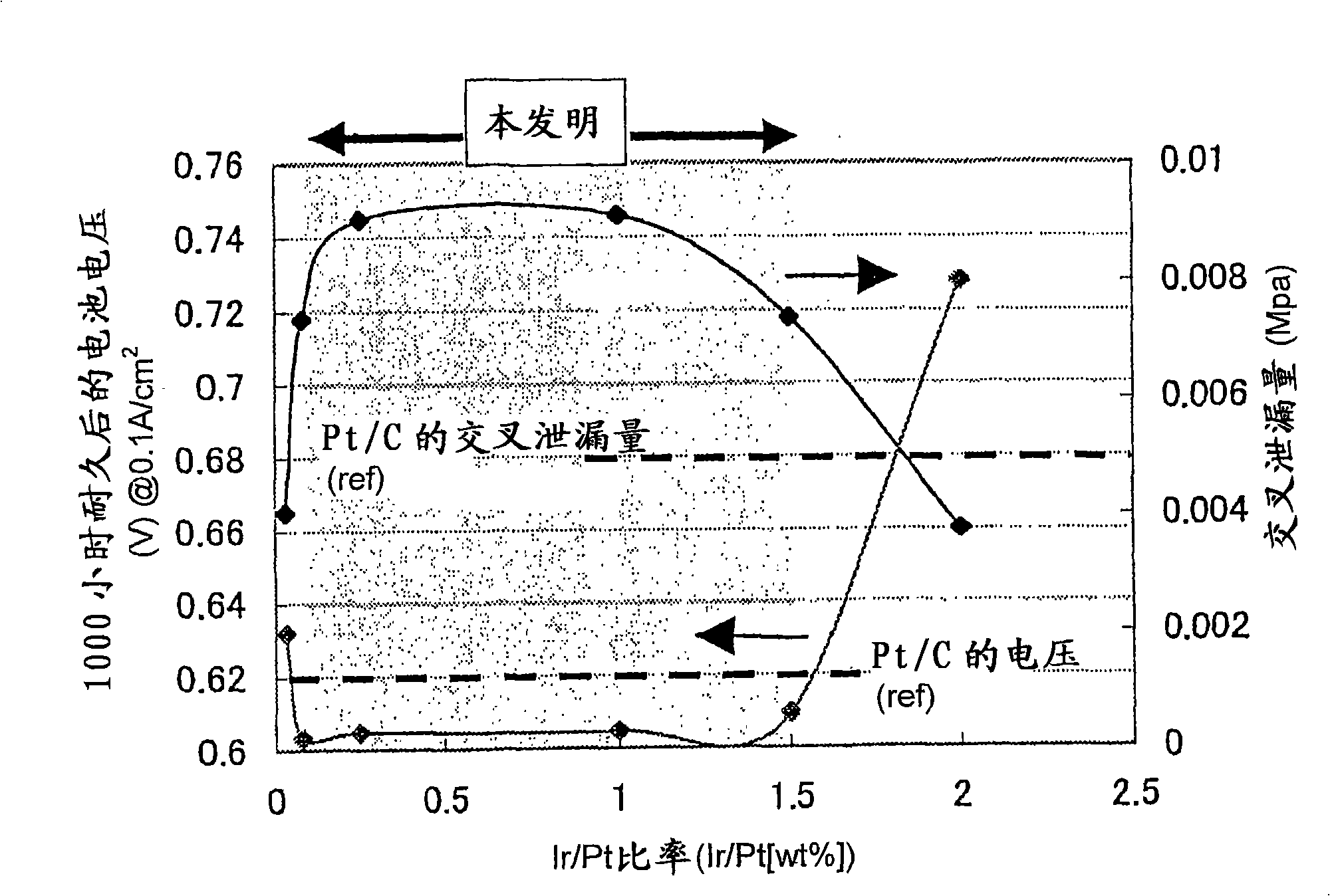

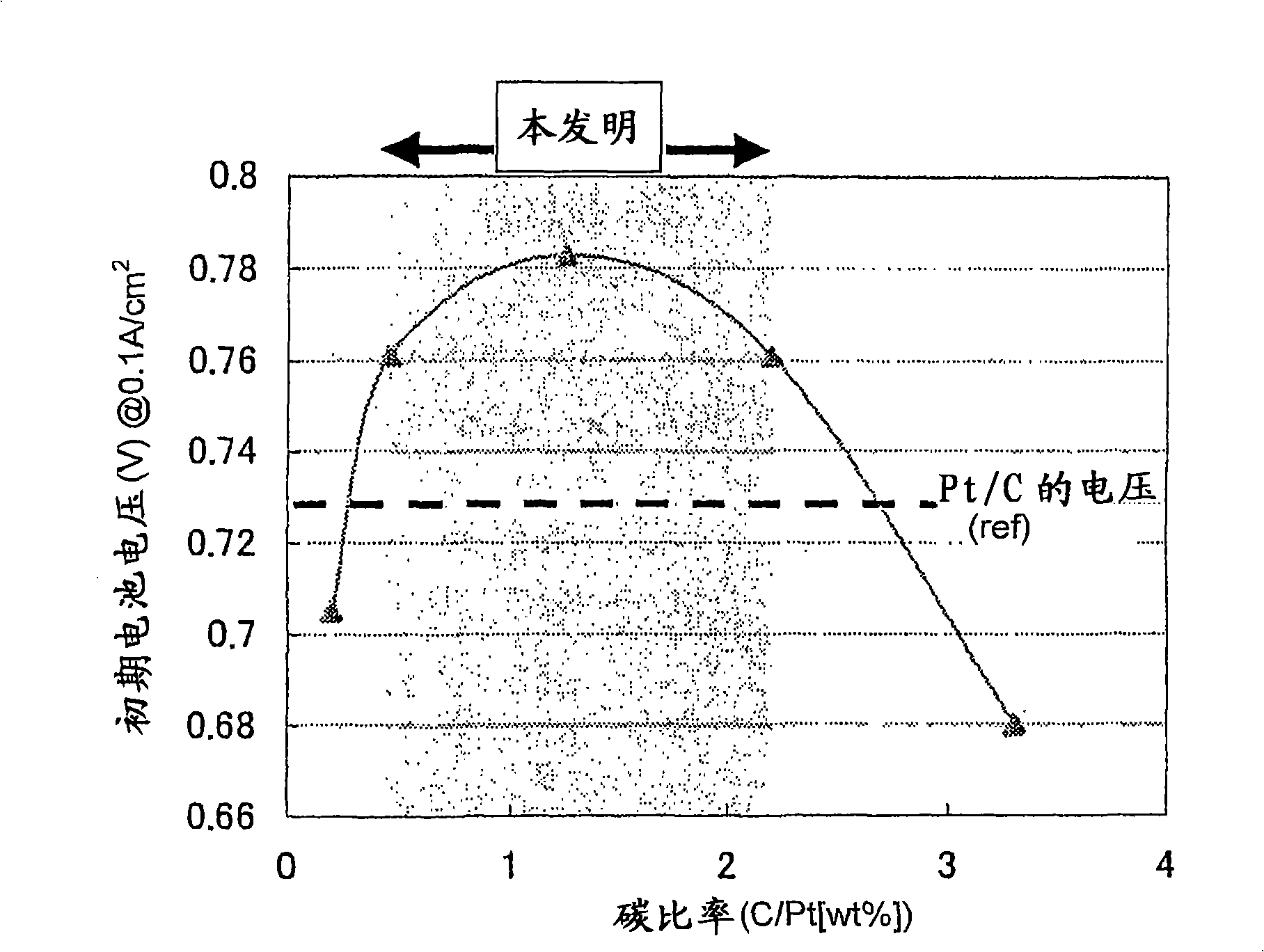

Fuel cell electrode catalyst comprising binary platinum alloy and fuel cell using the same

A fuel cell electrode and fuel cell technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of increasing the possibility of cross-leakage, and achieve the effect of improving initial performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

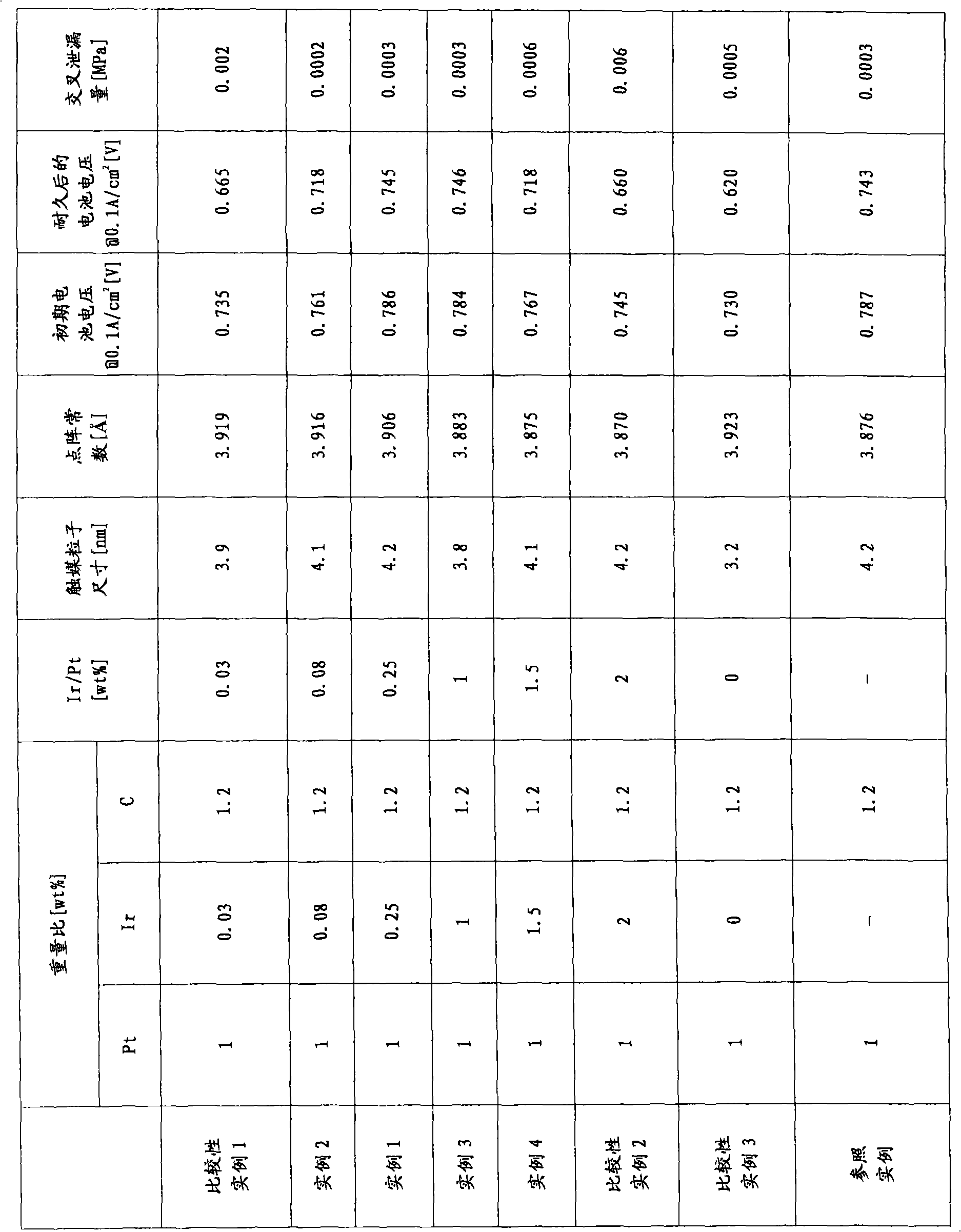

example 1

[0049] First, 4.95 g of a commercially available toner having a large specific surface area was added and dispersed in 0.5 L of pure water. A hexahydroxoplatinum nitrate solution containing 4.05 g of platinum and an iridium nitrate solution containing 1.00 g of iridium were dropped into the liquid dispersion in this order. The liquid dispersion is thoroughly mixed with the carbon. About 100 mL of 0.1N ammonia was added to the liquid dispersion, and the liquid dispersion was adjusted to a pH of 10. The corresponding hydroxides are formed and precipitated on carbon. The liquid dispersion was filtered and the powder containing was dried in vacuo at 100°C for 10 hours. Then, the powder was kept under a hydrogen atmosphere at 400° C. for 2 hours so as to be reduced. Next, the powder was kept at 600° C. for 2 hours in the presence of nitrogen for alloying.

[0050] The metal loading density of the obtained platinum alloy supported carbon powder catalyst was such that the catalys...

example 2

[0053] The fed amounts of carbon, platinum, and iridium were 5.33 g, 4.36 g, and 0.30 g, respectively. The product ratio of Pt, Ir, and C is 1:0.08:1.2 (wt% ratio). A catalyst was prepared in the same manner as in Example 1.

example 3

[0055] The fed amounts of carbon, platinum, and iridium were 3.81 g, 3.12 g, and 3.07 g, respectively. The product ratio of Pt, Ir, and C is 1:1:1.2 (wt% ratio). A catalyst was prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com