Automatic testing method of injection molding workpiece and inspection system thereof

An injection molding and automatic inspection technology, which is applied in the field of automatic inspection system for injection molding workpieces, can solve the problems of low production efficiency and manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

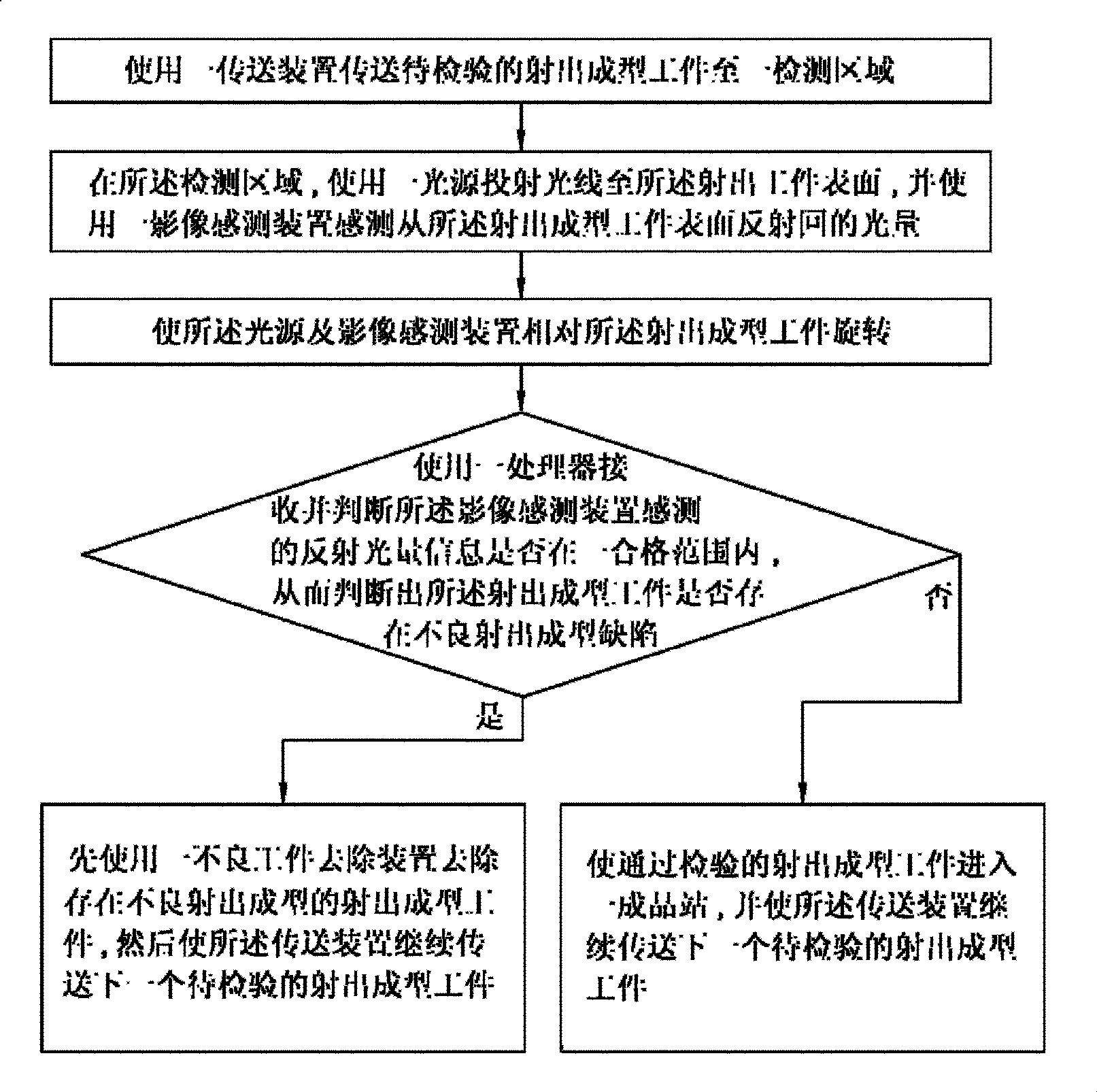

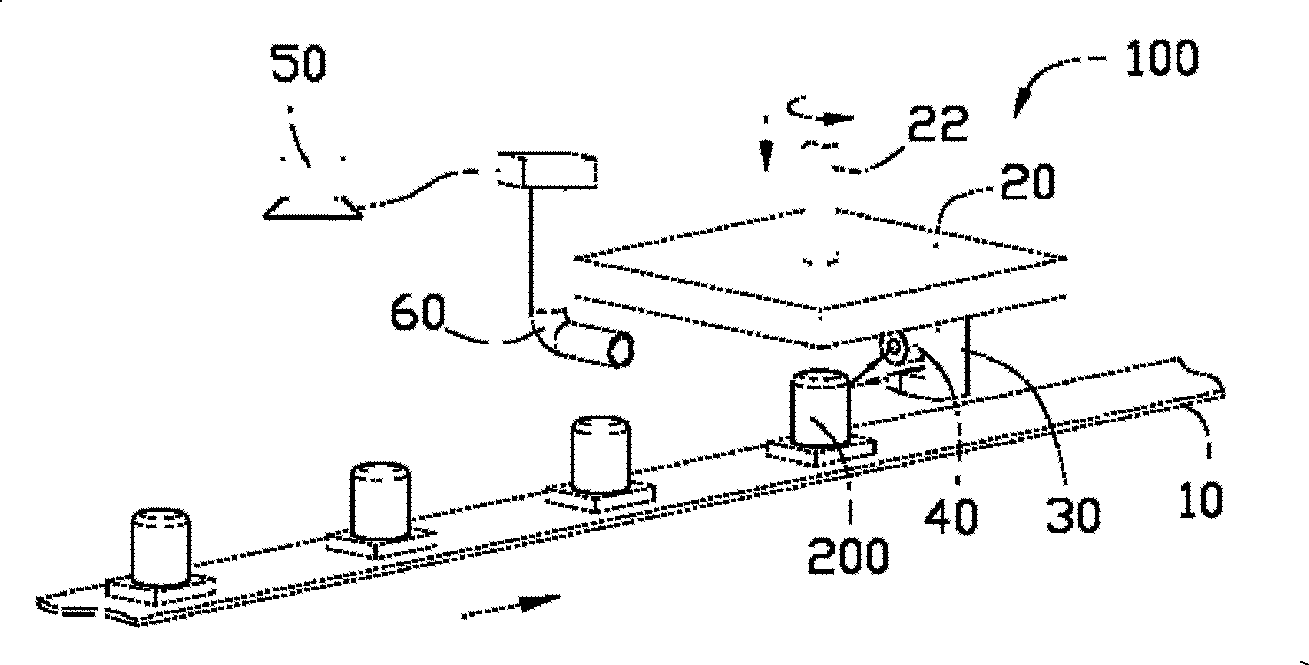

[0011] The automatic inspection method and inspection system for injection molded workpieces provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] see figure 1 , the injection molded workpiece automatic inspection method provided by the embodiment of the present invention includes the following steps;

[0013] (a) using a transfer device to transfer the injection molded workpiece to be inspected to an inspection area;

[0014] (b) in the detection area, using a light source to project light onto the surface of the injection molding workpiece, and using an image sensing device to sense the amount of light reflected from the surface of the injection molding workpiece;

[0015] (c) rotating the light source and image sensing device relative to the injection molding workpiece, so that the image sensing device senses reflected light from multiple locations around the surface of the injection molding work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com