PVC (polyvinyl chloride) heat-shrinkable label film and preparation method thereof

A heat-shrinkable, PVC resin technology, applied in the field of PVC heat-shrinkable label film and its preparation, can solve problems such as hidden dangers of environmental protection, poor softness and stiffness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

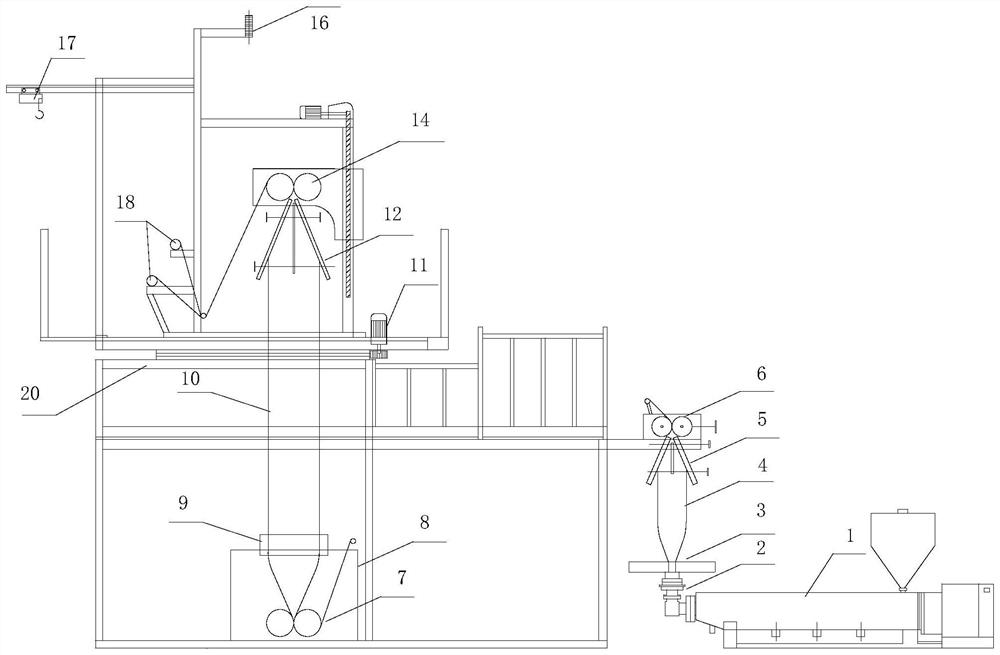

Image

Examples

Embodiment Construction

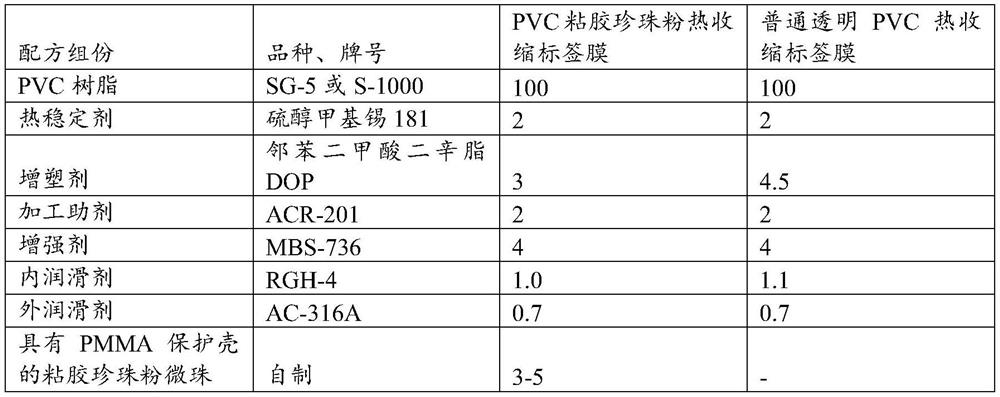

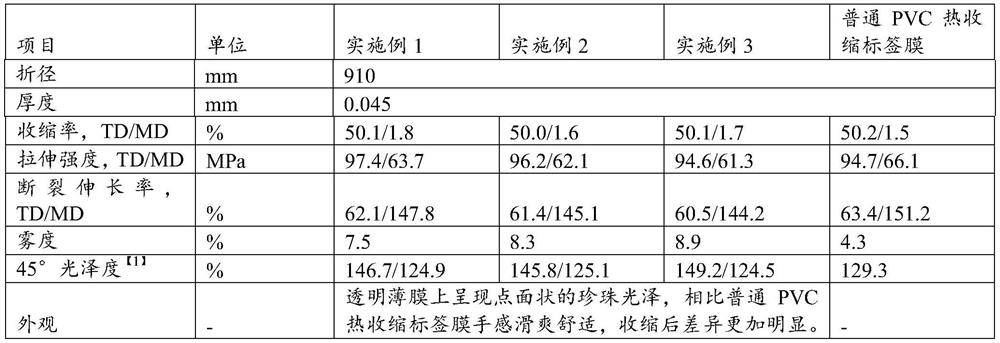

[0022] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

[0023] 1. Preparation of viscose pearl powder microbeads with PMMA protective shell

[0024] 1. Pearl powder is selected from micron-level (average particle size ≤5μm).

[0025] Coupling treatment: Soak pearl powder in 10-15% silane coupling agent aqueous solution for 2-4 hours. The amount of silane coupling agent is 1-2% of the mass of pearl powder. Prepare the aqueous solution in advance for use, or use more The coupling agent is used in an excess solution of the appropriate concentration. Remove and drain the water, bake at 120°C for 2 hours, and set aside.

[0026] The molecular structural formula of the silane coupling agent is generally Y-R-Si(OR)3 (in the formula, Y-organic functional group, SiOR-siloxyl group). Siloxy groups are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com