Device for monitoring and regulating an adhesive layer to a be applied when producing printed products

A technology of adhesive layer and application device, applied in the direction of adhesive for bookbinding, printing, measuring device, etc., can solve the problem of inability to determine the wrong position of analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

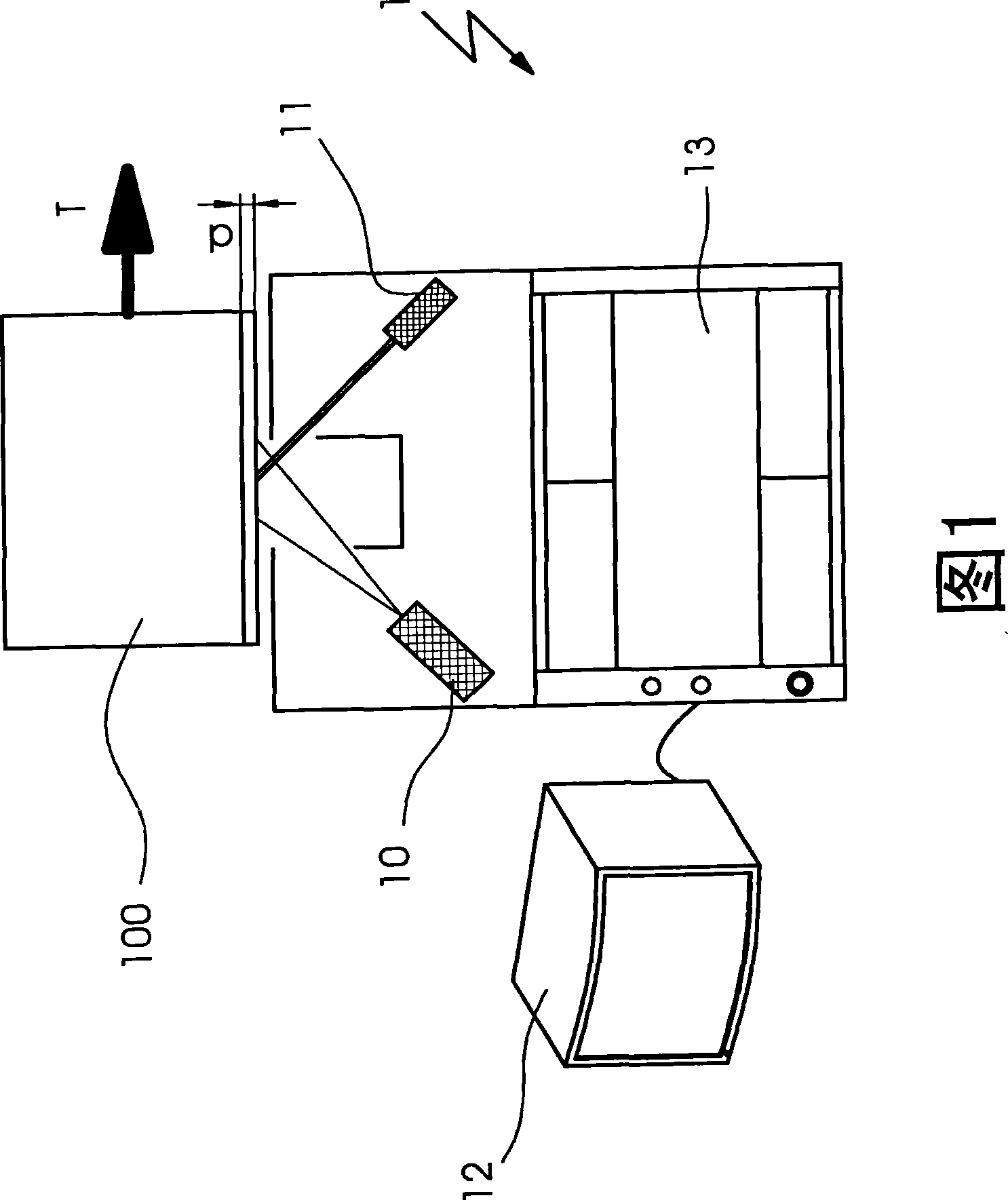

[0038]FIG. 1 shows a device 1 for controlling the adhesive layer thickness d by means of triangulation and a book block 100 provided with an adhesive layer. The book block 100 is moved in the conveying direction T past the measuring region of the device for controlling the thickness d of the adhesive layer. The device 1 for controlling the adhesive layer thickness d comprises an illumination unit 11 , a camera with an objective lens 10 , an evaluation device 13 and a display device 12 . An illumination unit 11 , for example a laser, projects a light spot onto the adhesive layer of the book block 100 , which is observed with a CCD or CMOS camera 10 . If the distance between the sensor and the surface of the adhesive layer is now changed, the angle at which the camera 10 captures the light spot also changes. Here, the connection of camera 10 -light source 11 and the two rays from and to the objective form a triangle, which is why it is called triangulation. In this case, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com