Upper-stacking and lower-hanging combined load static load test pile apparatus

A technology of static load test pile and load box, which is applied in the test of basic structure, construction, and basic structure engineering, etc., can solve the problems of heavy stacking sand bags, low construction efficiency, slow speed, etc., to reduce the overall center of gravity, reduce The effect of counterweight and height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

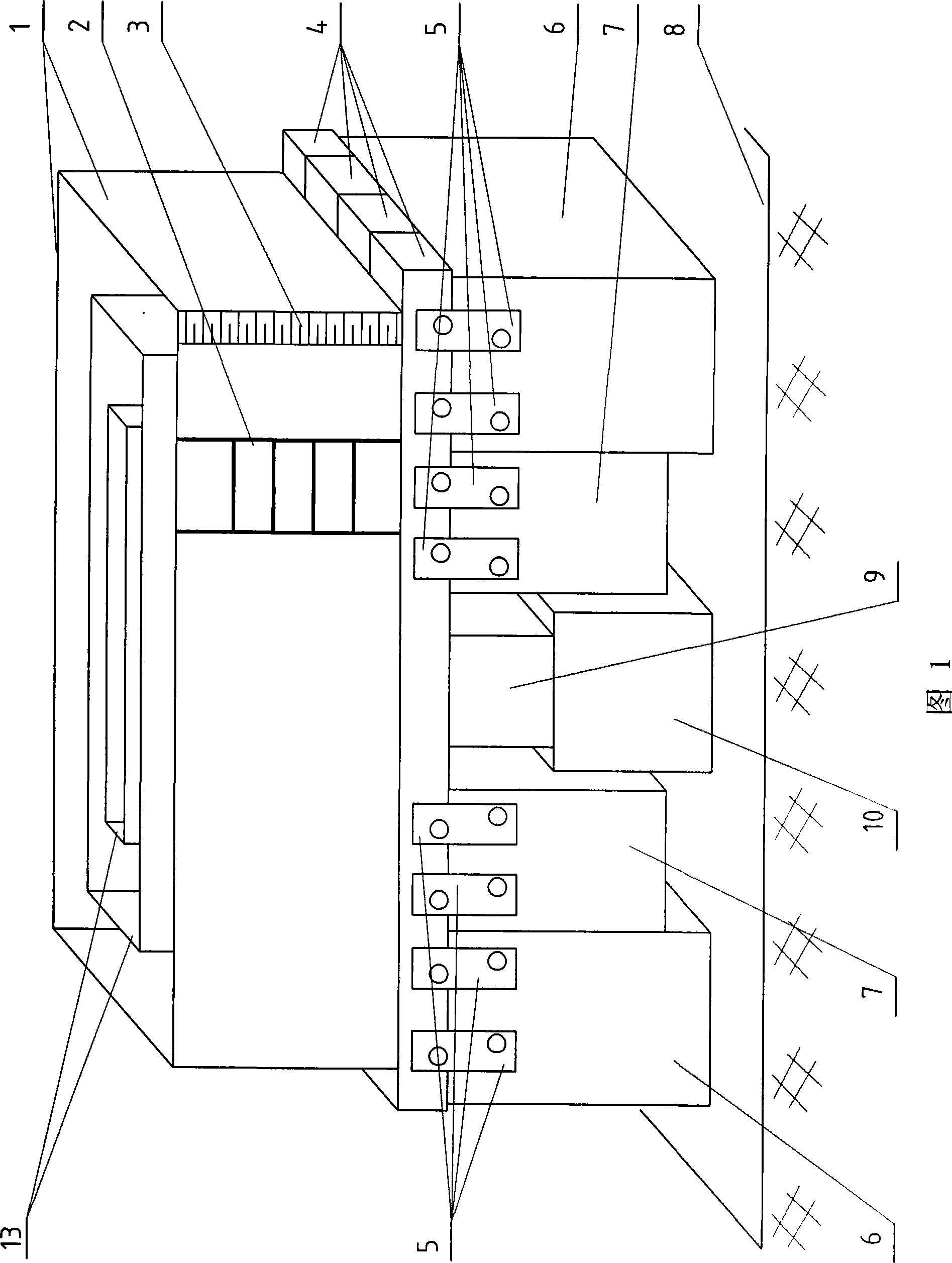

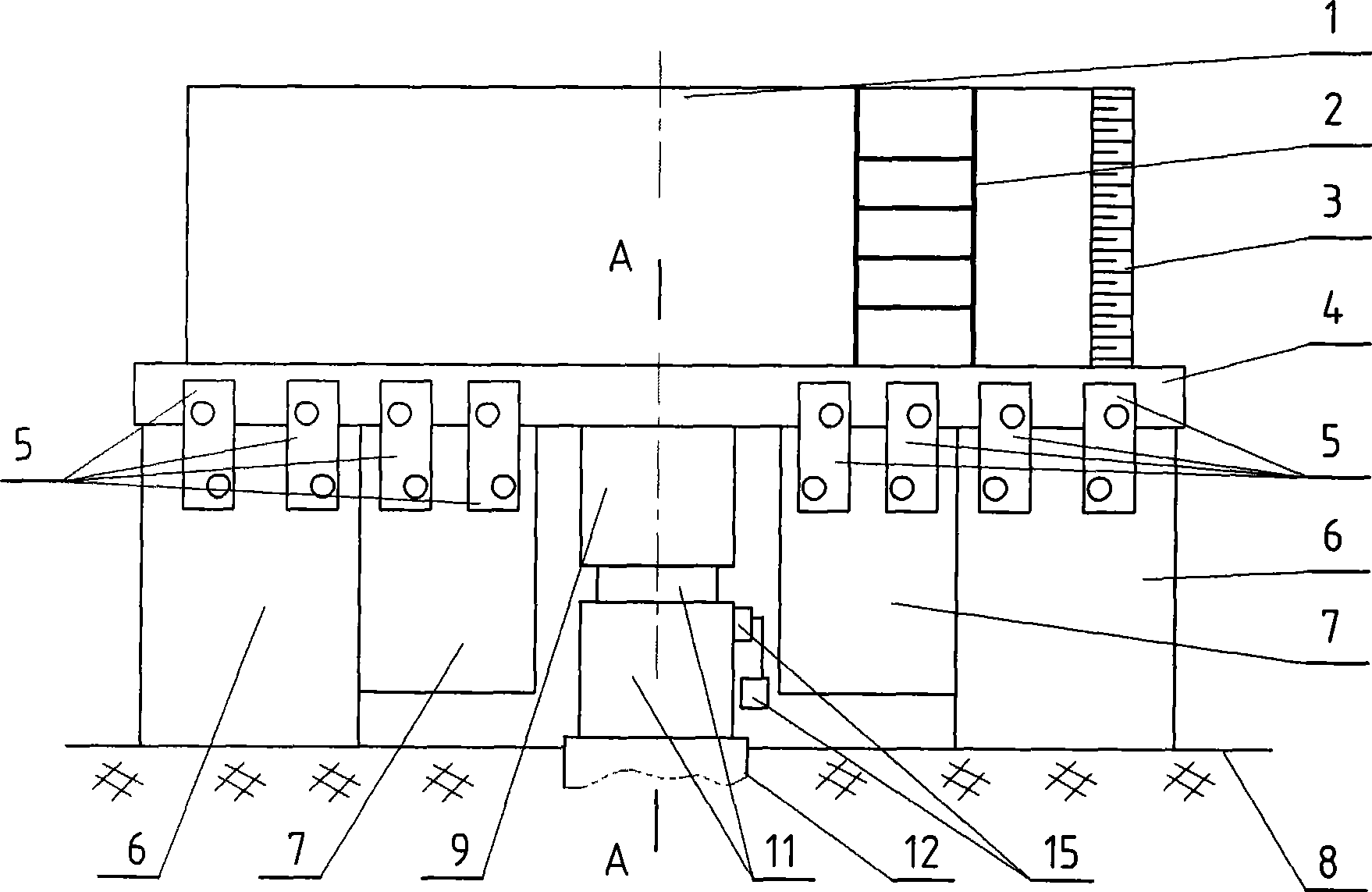

[0017] Embodiment 1 is shown in Figures 1-4: a static load test pile device with combined loads on top and bottom hanging. On both sides of the foundation pile 12 along the same straight line, the steel structure of the main beam is placed on the ground 8 at an equal distance from the foundation pile 12. Support 10, the two ends of main beam 9 are placed on the main beam steel structure support 10, and jack 11 is placed between main beam 9 and foundation pile 12; The length direction of 4 is symmetrical to the foundation pile 12 and is placed on the main beam 9, and the auxiliary beam 4 and the main beam 9 form a ballast platform. On the auxiliary beam 4, the upper pile steel structure load reinforcement box 1 is placed, and on both sides of the auxiliary beam 4 in the width direction, it is symmetrical to the foundation pile 12, and the lower load box 6 and the lower load box are attached to the lower beam support through the connector 5 7. In the last steel structure load s...

Embodiment 2

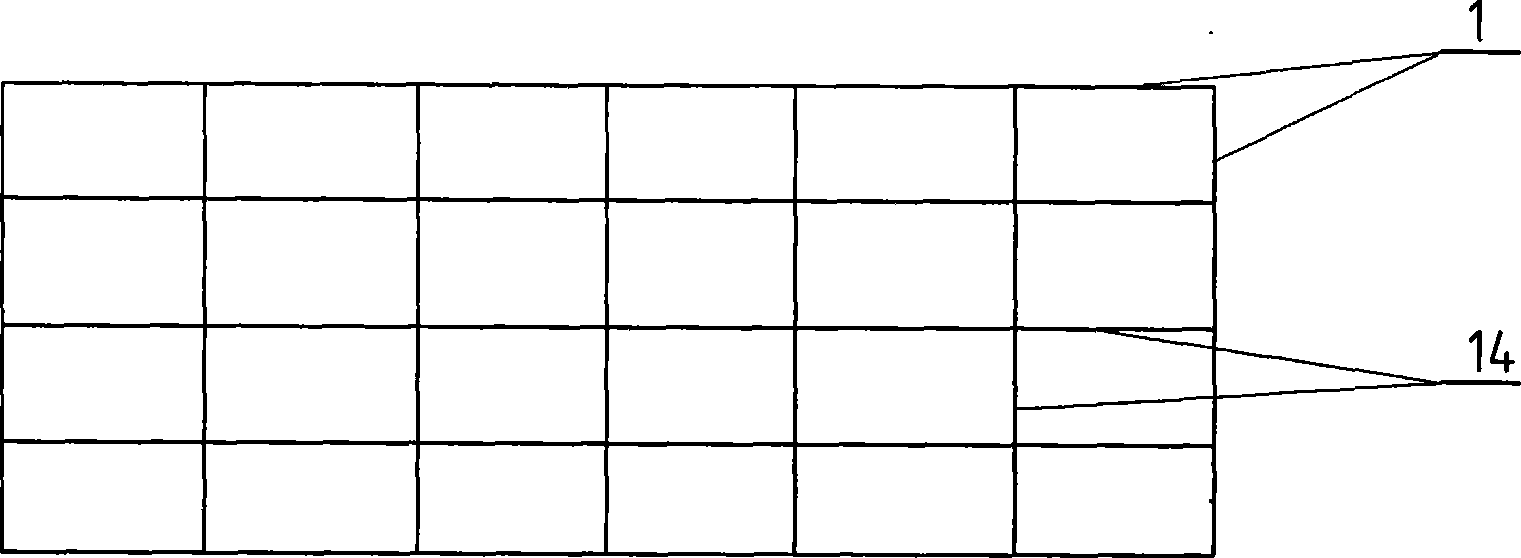

[0019] Example 2 as Figure 2-3 Shown: a static load test pile device with combined load on the top pile and bottom hanging. In the load reinforcement box 1 of the steel structure on the top pile, a "well" shaped reinforcement baffle 14 symmetrical to the vertical central axis of the foundation pile is positioned and fixed, or a strip-shaped reinforcement baffle 14 , triangle, diamond and other reinforced baffles. The ground clearance of hanging load box 7 is 10 centimeters larger than paying beam support and hanging load box 6 below. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com