Combined type air exhausting channel and method for assembling the same

An exhaust duct and combined technology, applied in the direction of vertical pipes, building components, buildings, etc., can solve the problems of waste, long exhaust ducts, breakage, corner drop, etc., and achieve labor saving, reasonable structure, and material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

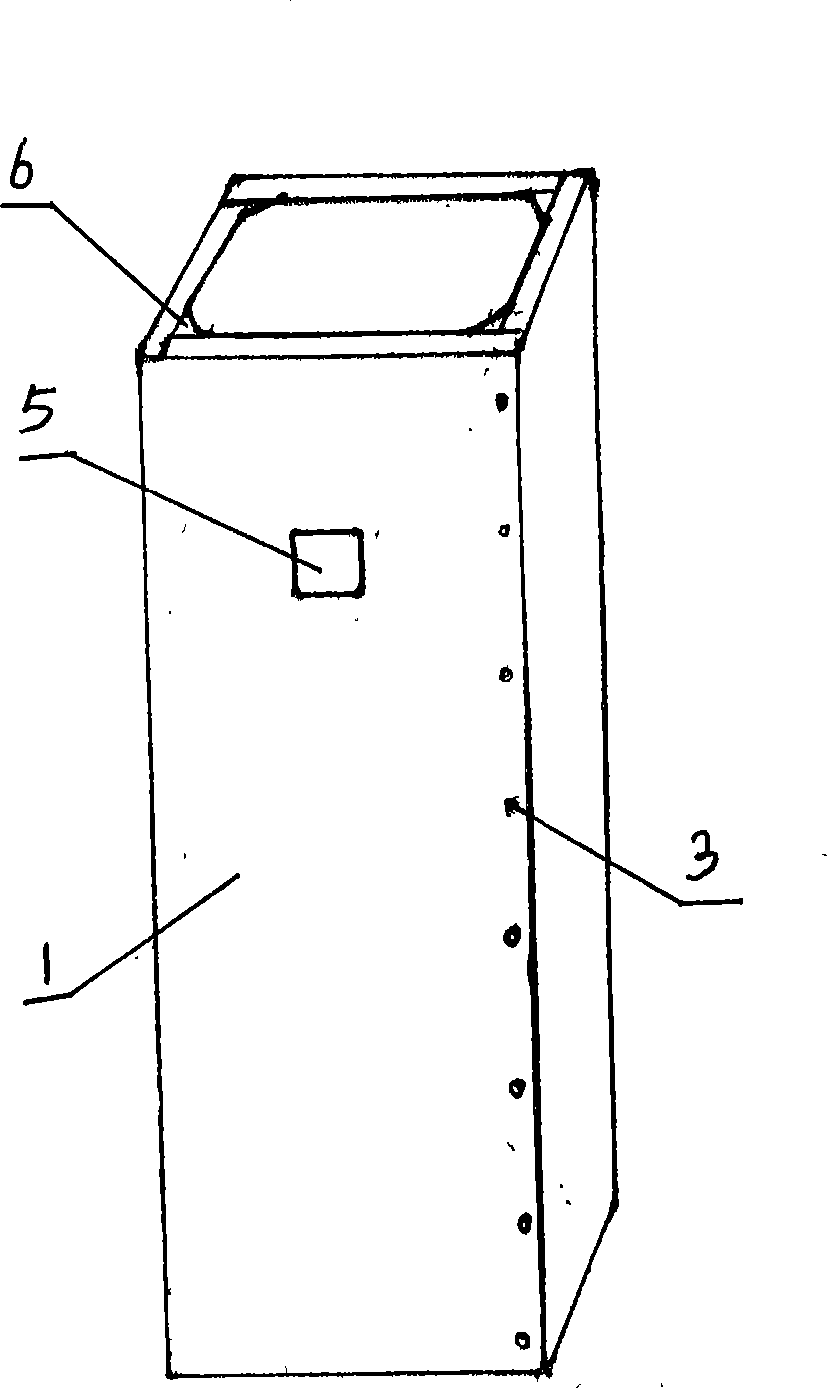

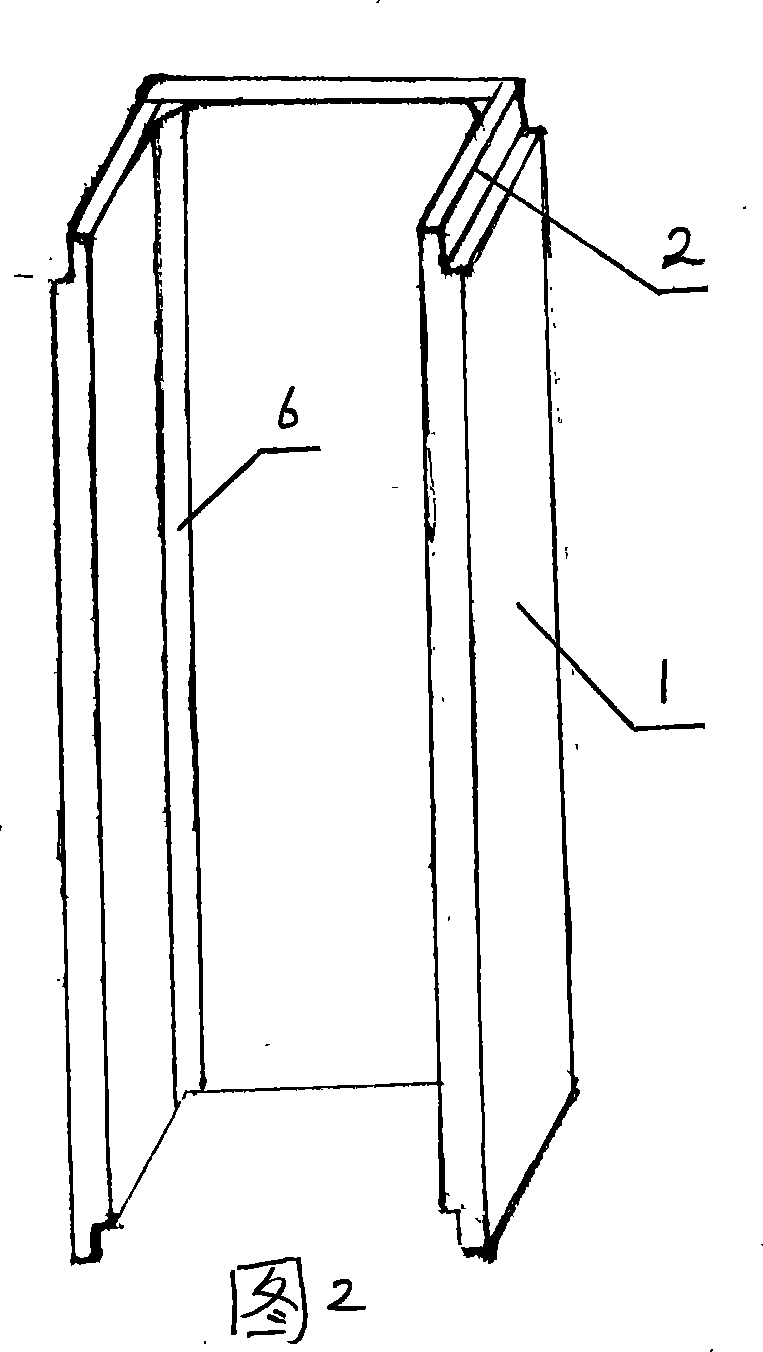

[0025] Embodiment one, with reference to the attached figure 1 , 2, 4, 5, 6.

[0026] In the embodiment, the combined exhaust channel is four exhaust channel plates 1, which are matched with each other and combined together to form a complete single-section exhaust channel. The two sides of the exhaust channel plate 1 are provided with slopes 7, and the single The air duct plates of the section air duct are matched and combined by slopes, then glued firmly, and connected with rivets 3 to form a single section air duct; the upper and lower sides of the air duct plates are provided with opposite direction The ladder 2, these steps form a matching concave-convex structure at the upper end and lower end of the single-section air duct, when several section air ducts are combined, through the mutual convex-concave matching, and then glued firmly, the stubble is completed processing.

[0027] In order to increase the strength of the exhaust duct, a reinforcing rib 6 is provided ins...

Embodiment 2

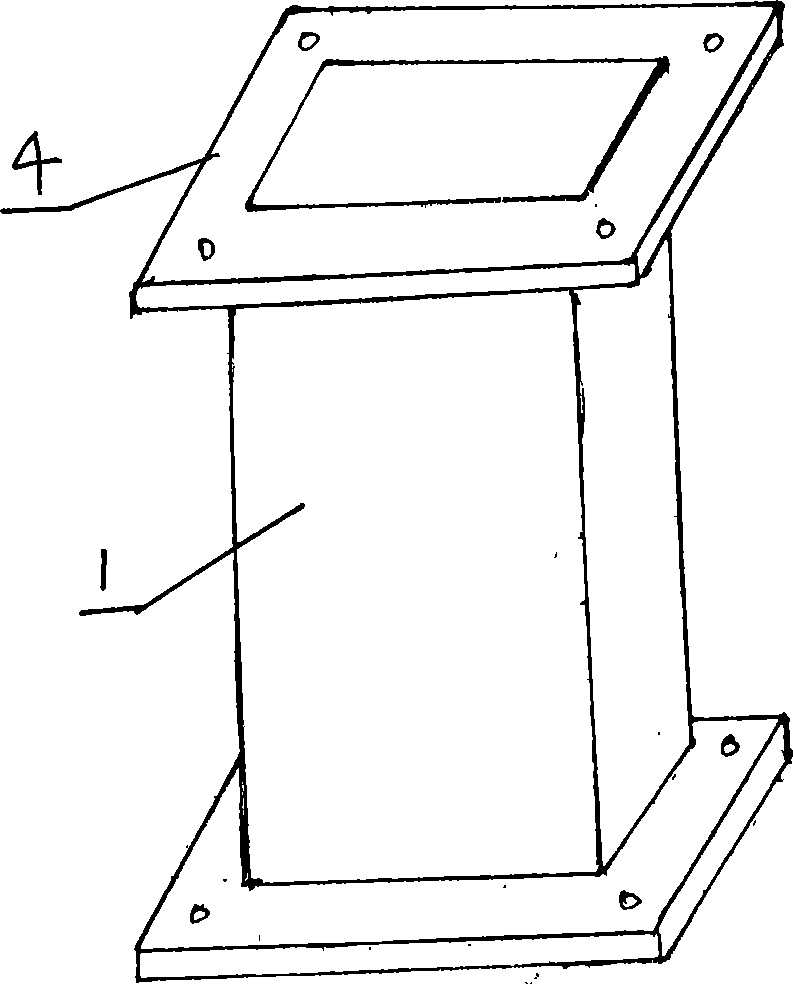

[0028] Embodiment two, referring to the attached image 3 .

[0029] The present embodiment is used for the air exhaust ducts of department stores, hotels, basements, etc., and flanges 4 are arranged on the top and bottom of the air exhaust duct plate 1, and the flanges are fixed on the ends of the air exhaust ducts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com