Slide characteristic value evaluation method, material selection method and design method of mechanism part

A technology of sliding characteristics and material selection, applied in the direction of analysis of materials, strength properties, material inspection products, etc., can solve problems such as multiple efforts and time, and achieve the effect of shortening the development period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

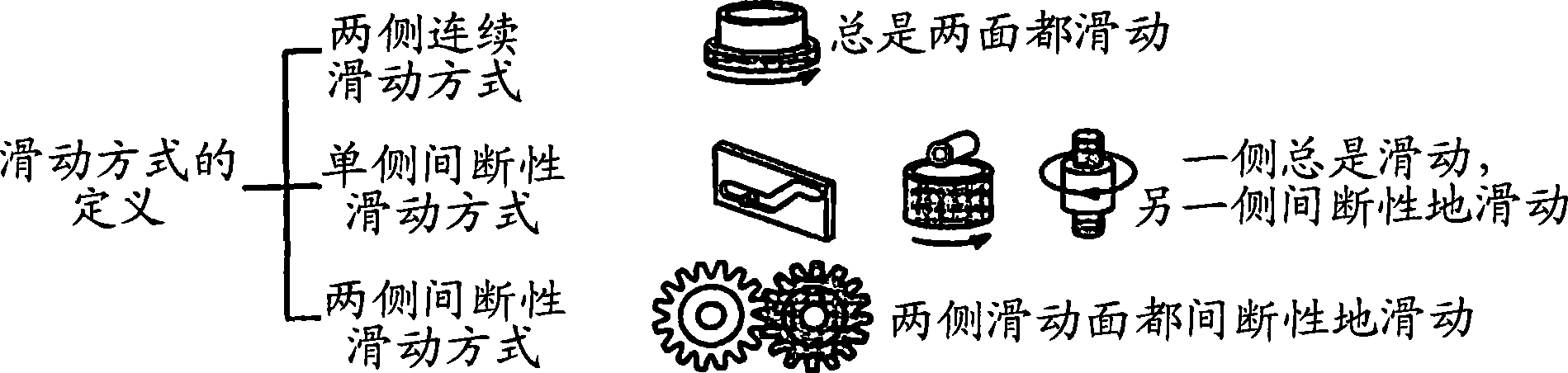

Method used

Image

Examples

Embodiment 1

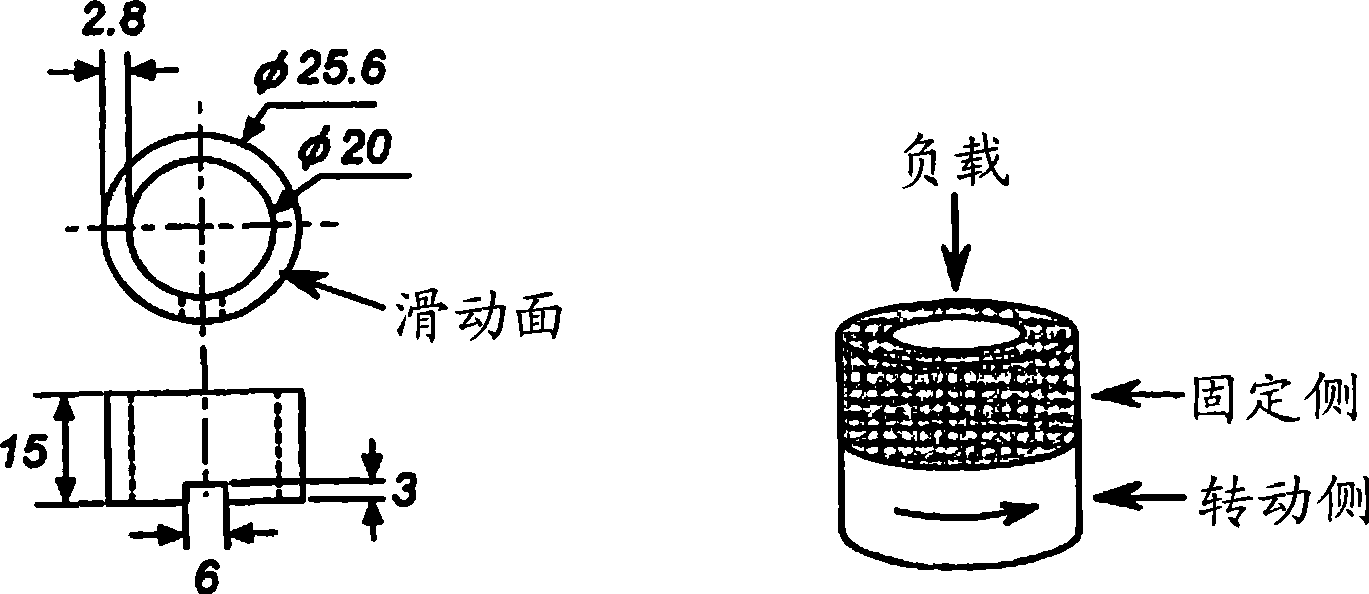

[0059] According to the present invention, the critical PV value between the hollow cylinder test pieces as a continuous sliding method is affected by the surface pressure ( Figure 5 ) to estimate the critical slip speed. The results are shown in Table 2. The surface pressure exceeds Figure 5 In case of the maximum surface pressure value, substitute Figure 5 The maximum surface pressure value for the calculation. As shown in Table 2, it is shown that the actual measurements agree well with the estimated critical slip speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com