Signal conditioning circuit for high precision measuring uV level voltage

A high-precision, voltage technology, applied in the field of measurement, can solve the problem of low precision of signal conditioning circuits, and achieve the effect of improving the performance of conditioning circuits, measurement accuracy, stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

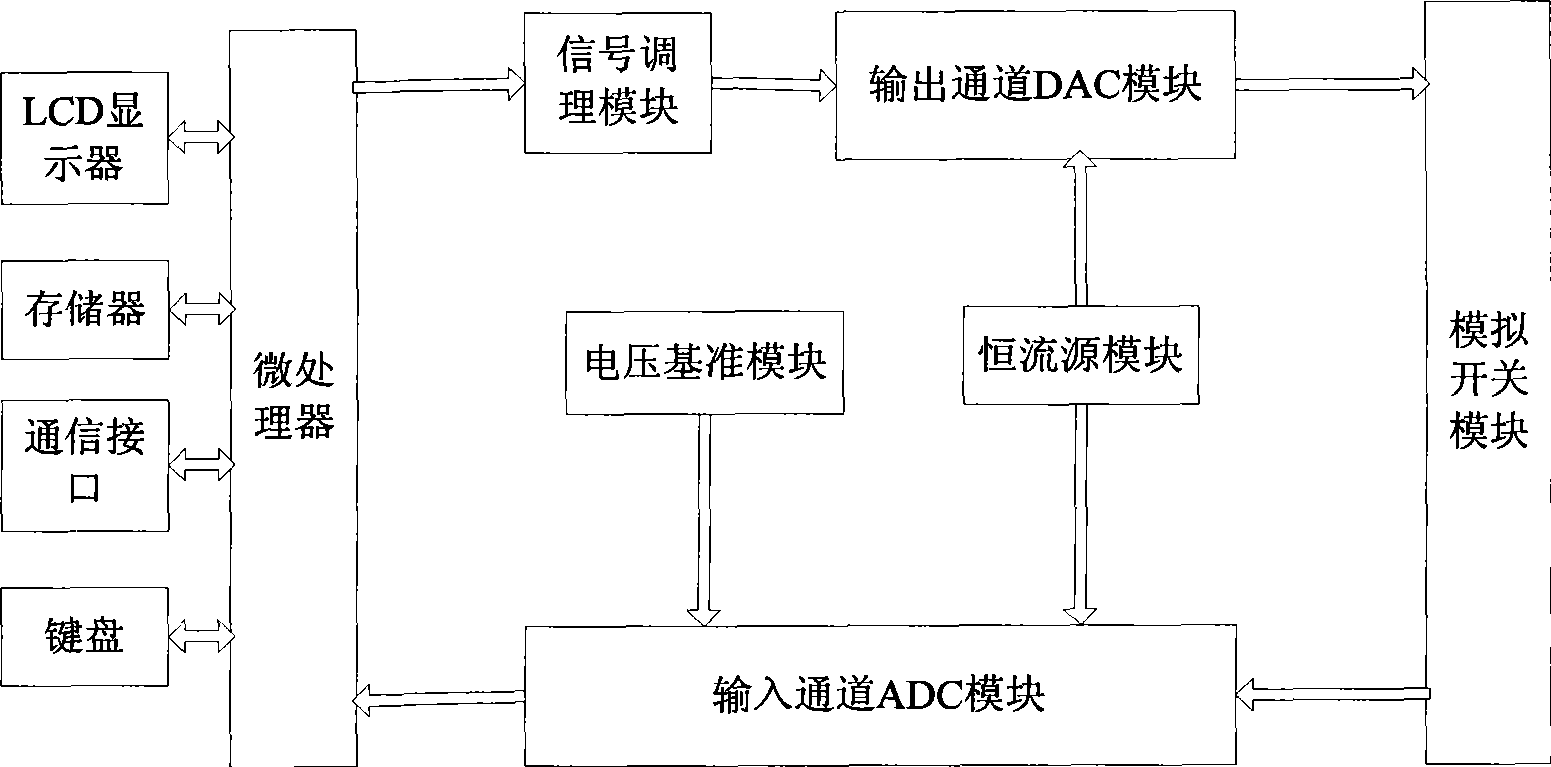

[0014] Such as figure 1 As shown, the process calibrator includes microprocessor, LCD display, memory, communication interface, keyboard, signal conditioning module, output channel DAC module, voltage reference module, constant current source module, input channel ADC module, analog switch module, micro The processor is connected to the LCD display, memory, communication interface, keyboard, input channel ADC module, and signal conditioning module, the output channel DAC module is connected to the analog switch module and the constant current source module, and the input channel ADC module is respectively connected to the analog switch Module, voltage reference module and constant current source module are connected.

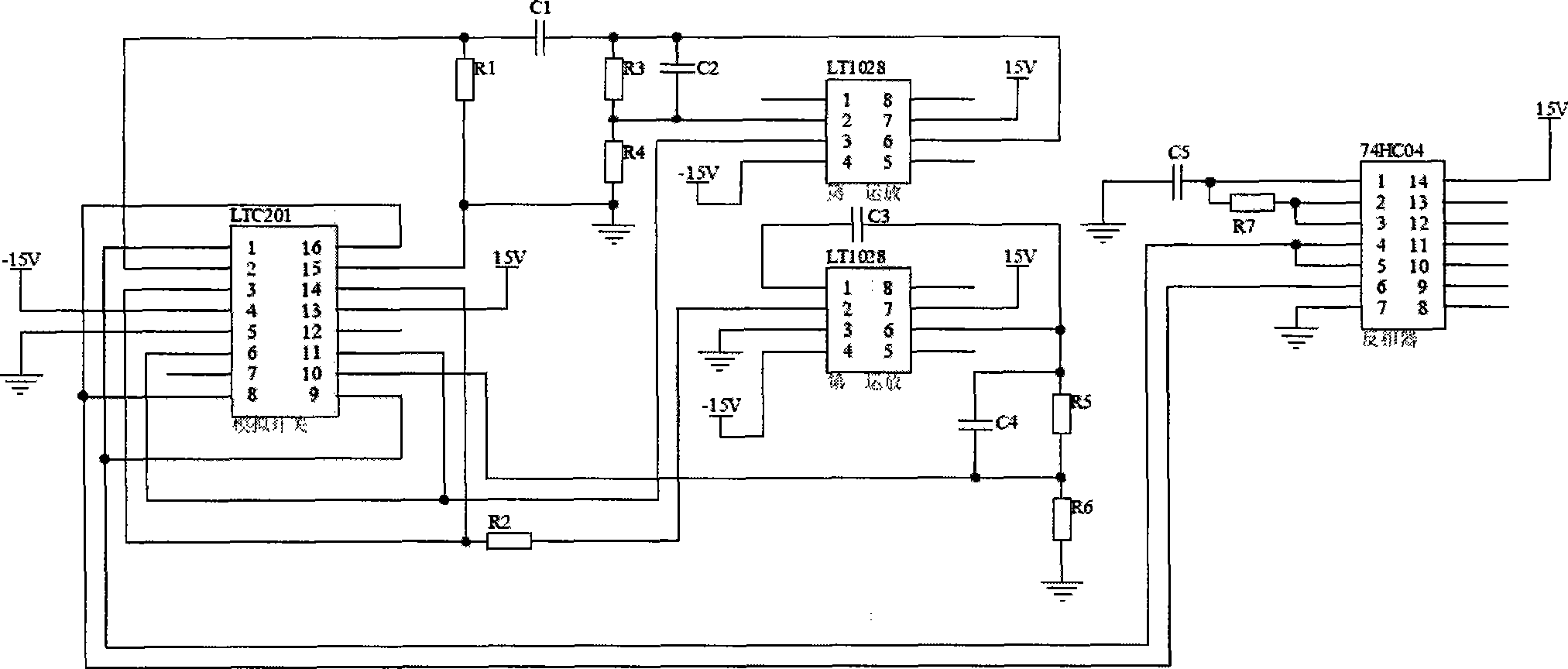

[0015] Such as figure 2 As shown, the signal conditioning circuit for high-precision measurement of uV level voltage is characterized in that: pin 1 and pin 9 of the analog switch LTC201 are respectively connected to pin 4 and pin 5 of the inverter 74HC04, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com