Infrared dual-band window protection film and manufacturing method thereof

A protective film and dual-band technology, applied in optics, instruments, optical components, etc., can solve the problems of high cost, complicated process, poor process repeatability, etc., to improve impact resistance, good process repeatability, and improve controllability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

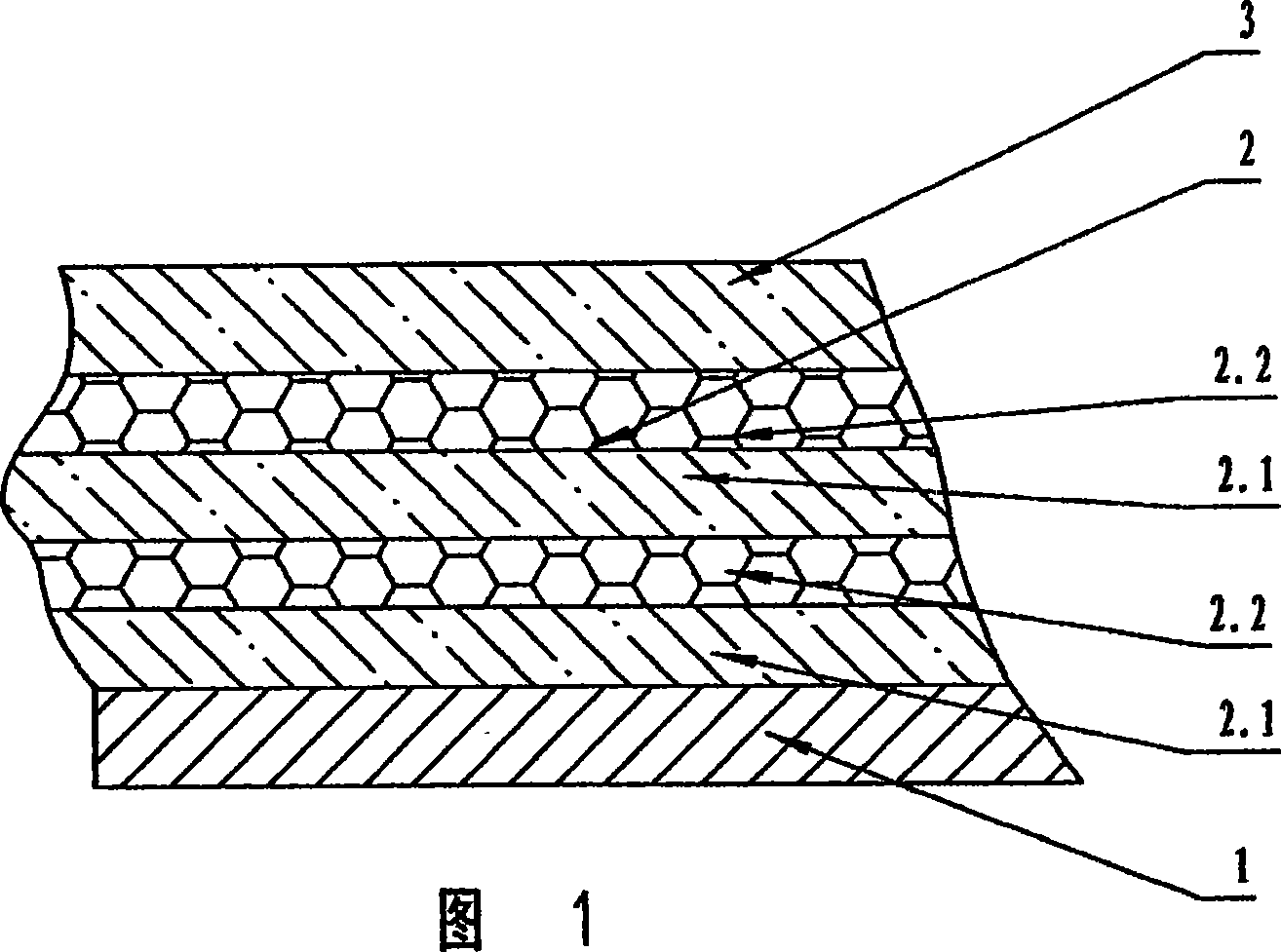

[0044]As shown in Figure 1, an infrared dual-band window protective film is a film system composed of a substrate 1 and at least one group of intermediate protective composite films 2 and an outermost protective film 3 that are sequentially attached to the substrate 1; The above-mentioned intermediate protective combination film 2 is composed of a germanium carbide film and an upper film 2.2 of a bottom layer film, or is composed of a diamond-like film of a bottom layer film 2.1 and a germanium carbide film of an upper layer film 2.2; the outermost layer The protective film 3 is a diamond-like carbon film, which is a diamond-like carbon film superimposed on the uppermost layer of the intermediate protective composite film 2, or is the uppermost diamond-like carbon film 2.2 of the intermediate protective composite film 2. The refractive index of the germanium carbide film is 3.0-3.9; the diamond-like film in the intermediate protective composite film 2 is the bottom film 2.1 or ...

Embodiment 2

[0045] Embodiment 2: Different from the above embodiment 1, the material of the base 1 is germanium, the intermediate protective composite film 2 is 6 groups, and the thicknesses of the upper layer films (diamond-like film) of the first group to the sixth group are respectively 43.89 nm, 59nm, 30nm, 802nm, 293nm and 2000nm. The uppermost diamond-like film is also the outermost protective film 3; the refractive index of the germanium carbide film is 3.9.

Embodiment 3

[0046] Embodiment 3: Different from the above-mentioned embodiments 1 and 2, the material of the base 1 is zinc sulfide; the intermediate protective composite film 2 is 1 to 6 groups, and the bottom film 2.1 of each group is a germanium carbide film and the upper film 2.2 is The diamond-like film is 10-2000nm. In this embodiment, the intermediate protective composite film 2 is divided into 2 groups. The bottom film 2.1 of the first group is a germanium carbide film and the upper film 2.2 is a diamond-like film with a thickness of 1563nm. The bottom film 2.1 of the second group is a carbonized film. The thickness of the germanium film and the diamond-like film of which the upper film 2.2 is the outermost protective film 3 is 100nm. The germanium carbide film has a refractive index of 3.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com