Sound-absorbing insulation part having hardening embossings

一种隔离件、吸声的技术,应用在车辆部件、发动机元件、通过隔热保护管道等方向,能够解决隔离件生产复杂和昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

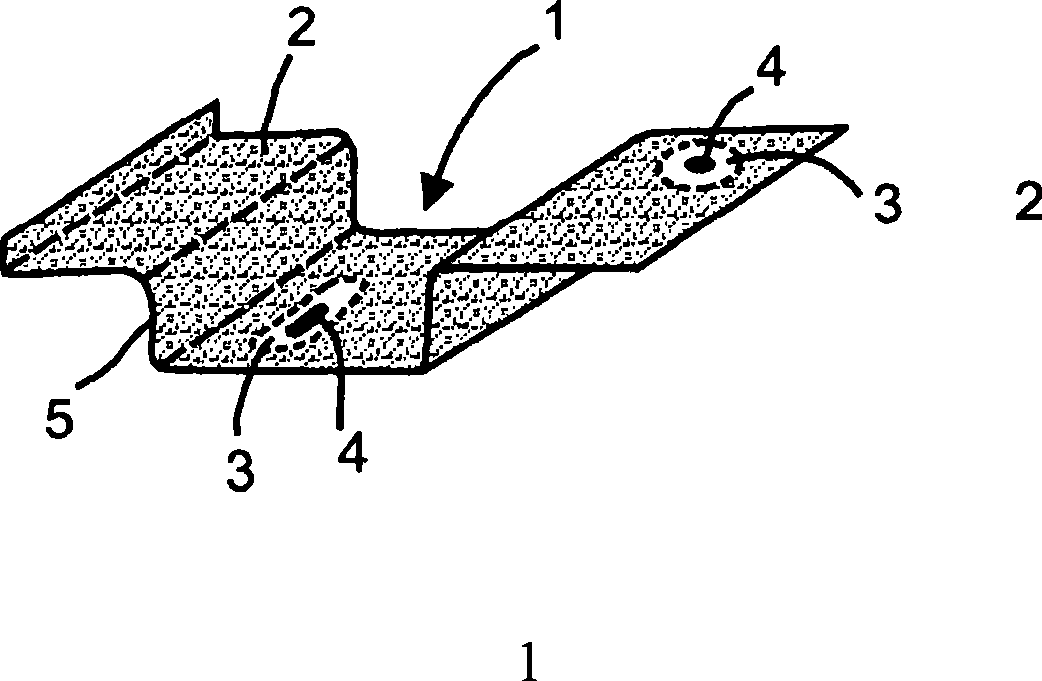

[0023] Figure 1 shows a perspective view of an insulating panel with a design suitable for use. The heat insulating board comprises a plate-shaped part 1 , also referred to simply as a “plate” below, on which slot-shaped holes 2 are distributed. The distribution of said slotted holes 2 lies within the range of normal industry practice; in particular, the free perforation area 3 may have fastening holes 4 for supporting fastening means. These free perforation areas 3 can also be used for inscriptions or for reliable production. It falls within the normal industry practice to also provide this type of plate 1 with a bead 5 to further enhance the mechanical stability of the plate 1 .

[0024] The thermal insulation panel preferably comprises a non-corrosive panel 1 made, in particular, of aluminum. Aluminum sheets with a thickness of 0.3 to 0.5 mm are preferably used. Of course, the plate may also comprise aluminum foil with a thickness of eg 0.1 to 0.3 mm or a thick aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com