Full-automatic capping, de-capping, box-turnover and material feeding integrated machine

A fully automatic feeding technology, which is applied in liquid handling, conveyor objects, emptying containers, etc., can solve the problems of high skill and knowledge requirements for maintenance workers, large overall investment, high technical difficulty, etc., and achieve compact structure and high feeding efficiency High, increase the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

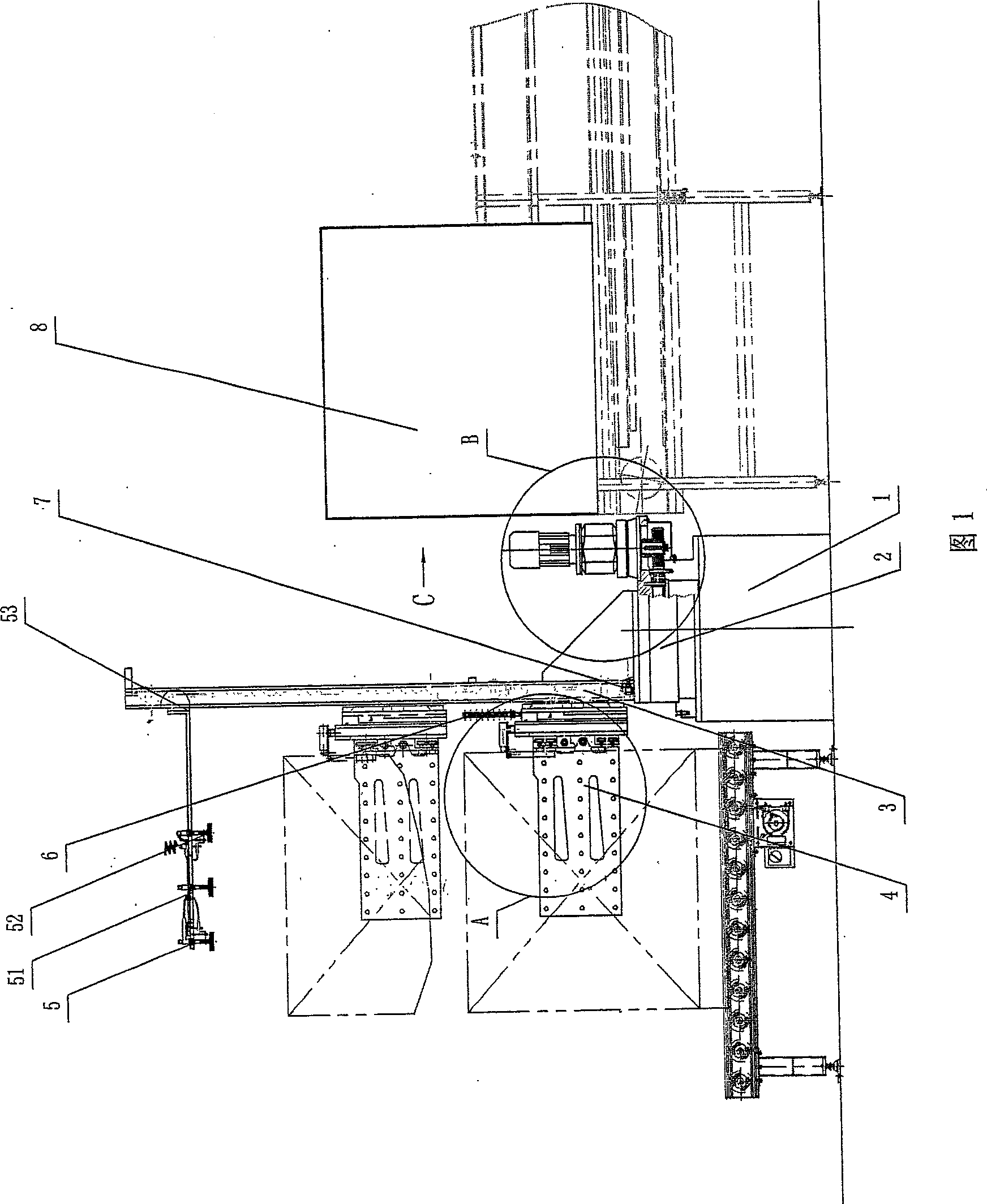

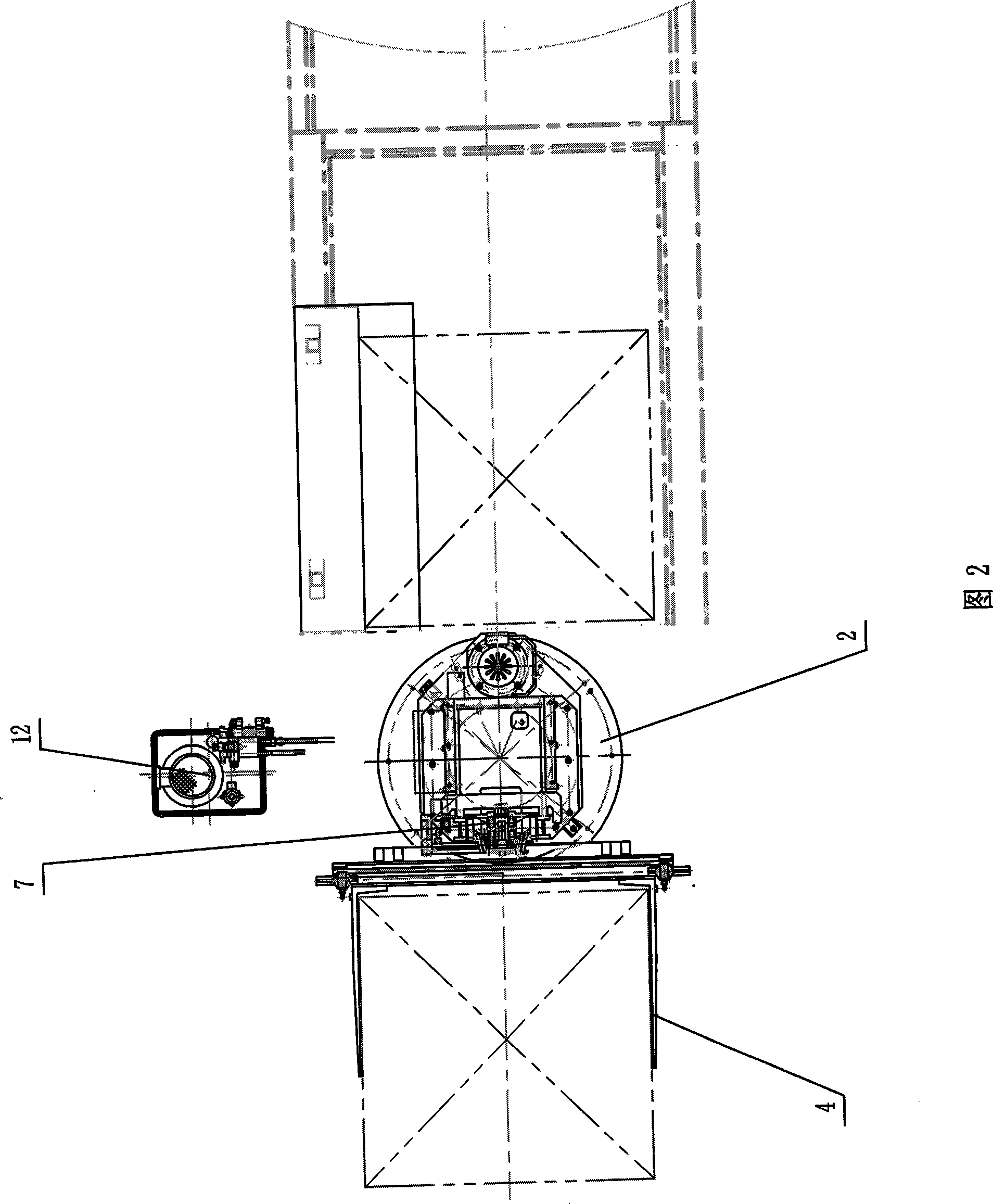

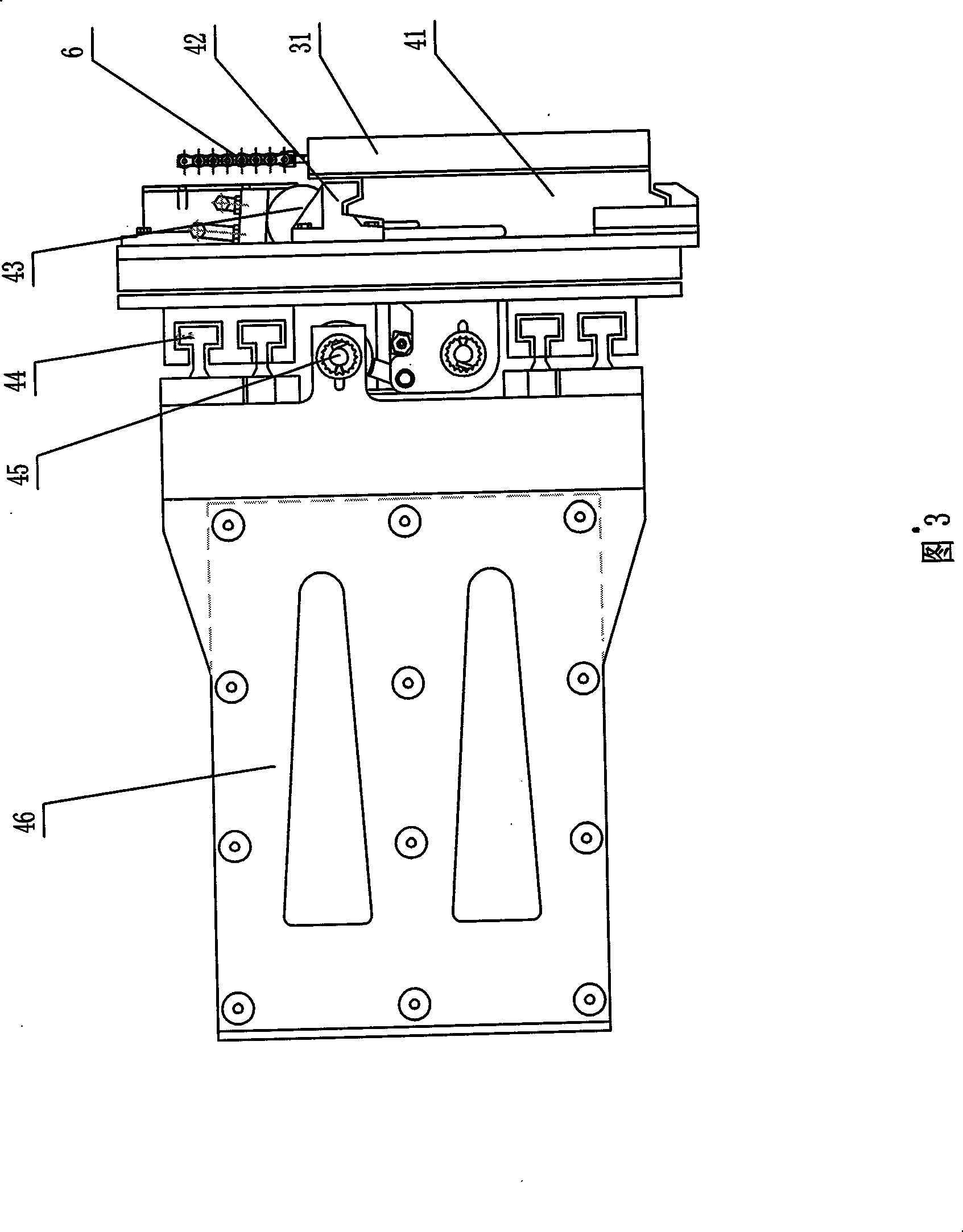

[0029] The fully automatic integrated machine for adding caps, removing caps, and turning boxes and feeding provided by the present invention includes a base 1, a rotary table 2 disposed on the base 1, a lifting frame 3 mounted on the rotary table 2, and a lifting frame 3 The clamping and turning device 4 and the lid pick-and-place device 5 on the top are as shown in Figure 1, wherein the lifting frame 3 is a door-shaped frame, and the lower end of the lifting frame 3 is fixed on the rotary table 2, and together with the rotary table 2 Rotate to form a rotary lifting frame 3, the lifting frame 3 is provided with a slide rail, the slide rail is provided with a sliding piece 31, the sliding piece 31 is connected with the lifting chain 6, as shown in Figure 3, the lifting chain 6 is connected with the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com