Aseptic half-adding stopper method

A technology of rubber stopper and feeding hopper, which is applied in the field of aseptic semi-stopper, can solve the problems of rubber stopper contamination, poor sterility, and pollution, etc., and achieves the effect of high sterility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A method of aseptic semi-stoppering, completed by the following steps:

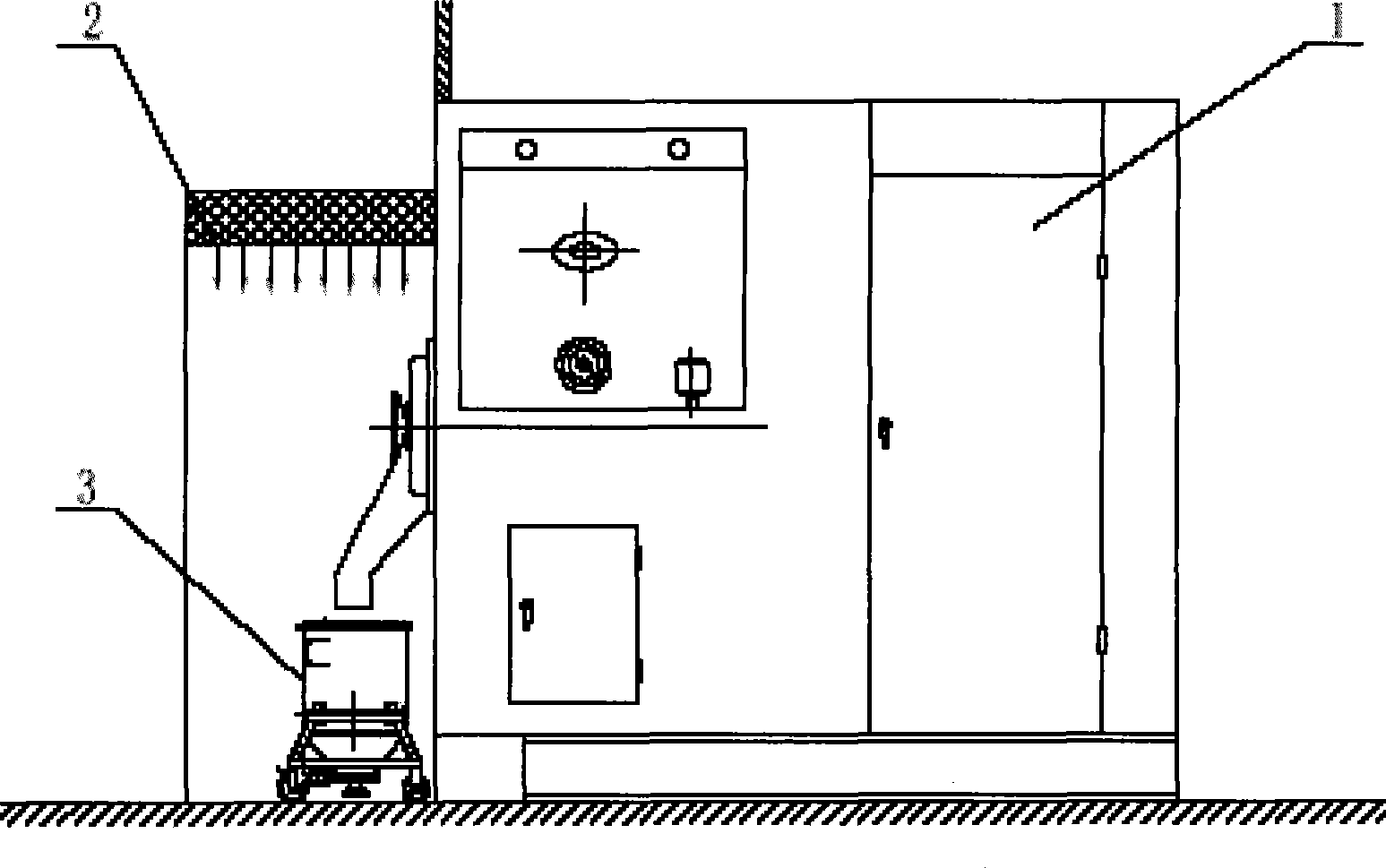

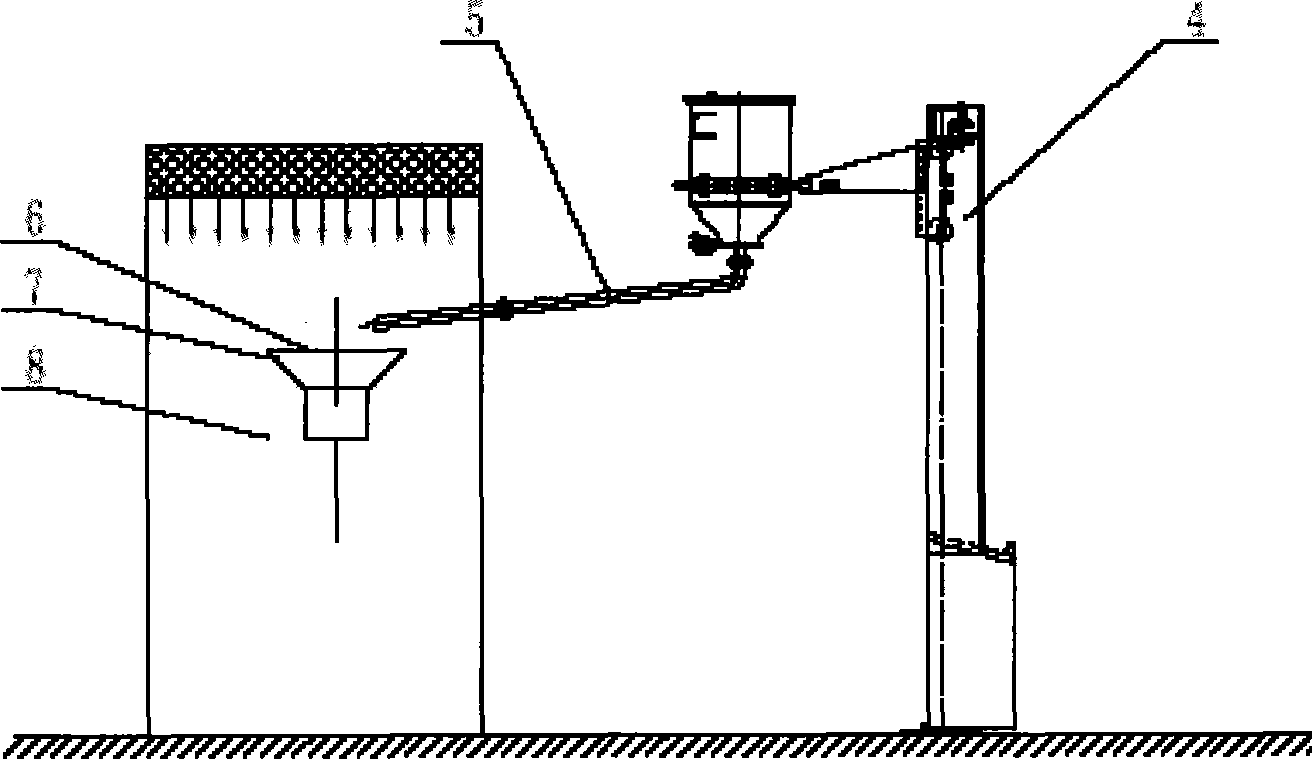

[0022] The first step is to install a sterile isolation barrier 2 outside the outlet of the rubber stopper cleaning machine 1, such as figure 1 shown;

[0023] In the second step, the untreated rubber stoppers are loaded into the rubber stopper cleaning machine 1, and the rubber stoppers in the rubber stopper cleaning machine 1 are sequentially cleaned, sterilized, silicified, and dried;

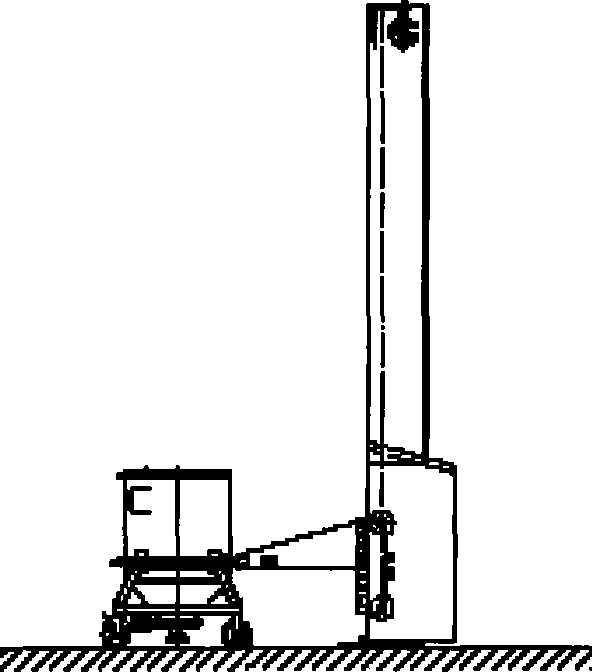

[0024] In the third step, the transfer barrel 3 sterilized by the dry heat sterilizer is placed under the outlet of the rubber stopper washing machine 1 in the sterile isolation barrier 2, the cover of the transfer barrel 3 is opened, and the rubber stopper washing machine 1 is opened. start to discharge the sterilized rubber stoppers from the discharge port, and after the discharge is completed, close the cover of the transfer barrel 3 and the discharge port of the rubber stopper cleaning machine 1 in sequence;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com