Glass severing device and method

A cutting device and glass technology, applied in glass cutting devices, glass production, identification devices, etc., can solve the problems of time-consuming, unable to cool glass plates, etc., and achieve the effect of increasing cutting speed and stabilizing formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Next, preferred embodiments for carrying out the glass cutting device and method of the present invention will be described with reference to the drawings.

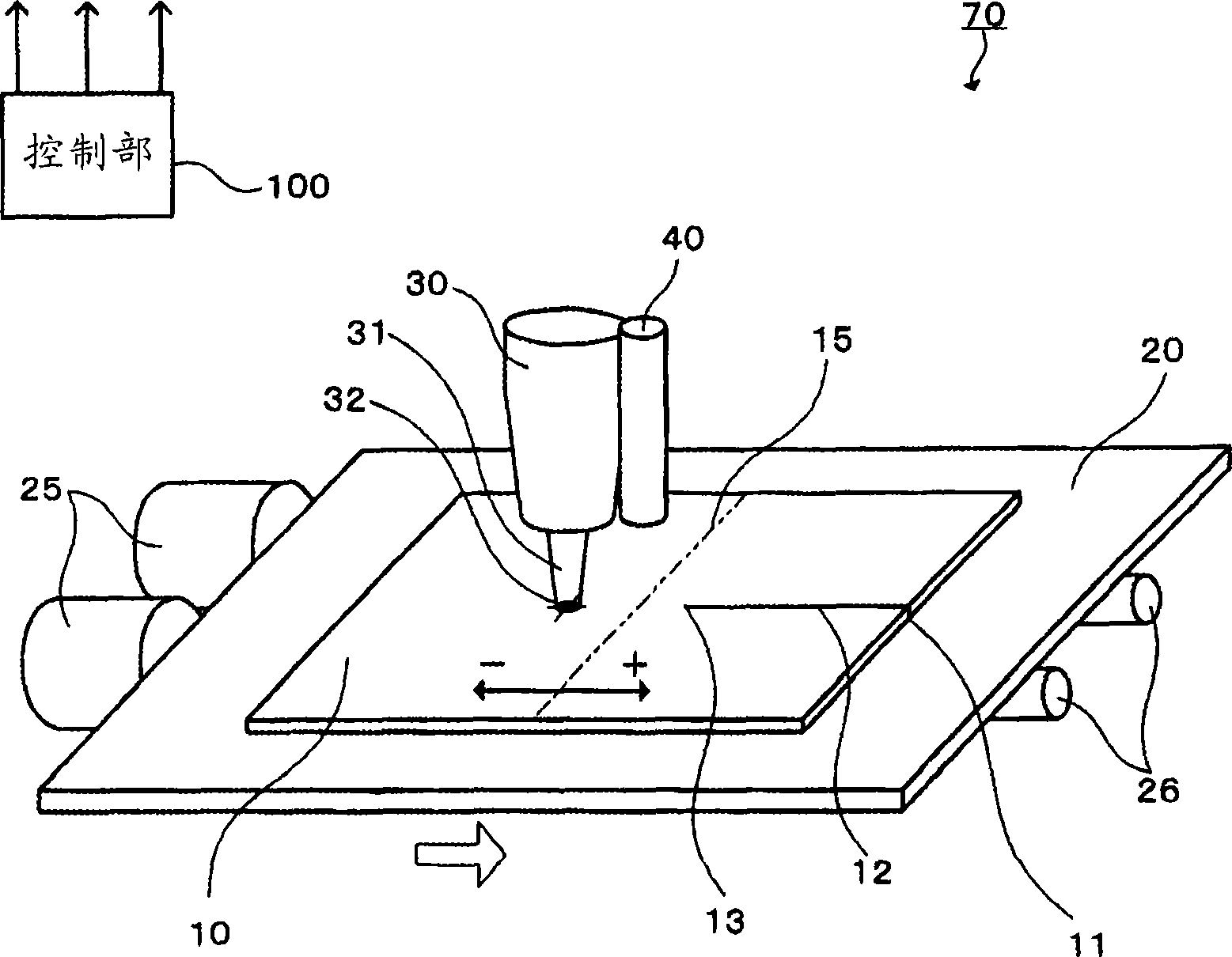

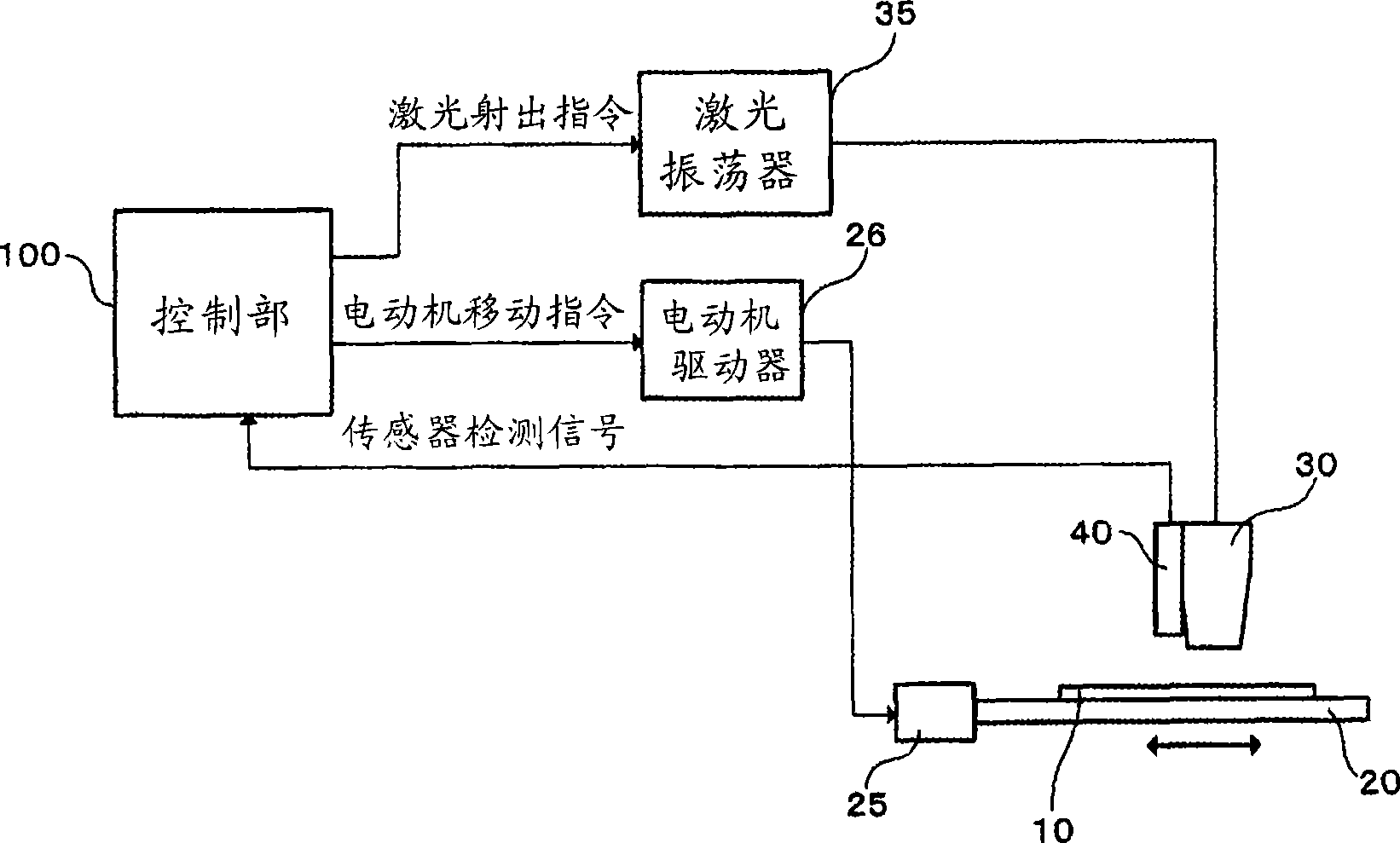

[0021] figure 1 It is a schematic diagram which shows the glass cutting apparatus and method of embodiment of this invention. This glass cutting device 70 has a placement plate 20 , a placement plate motor 25 , a ball screw 26 , a laser emitting unit 30 , and a sensor 40 .

[0022] The mounting plate 20 on which the glass plate 10 is placed has two nuts not shown below, and each nut is similarly connected to a ball screw 26 arranged below. A mounting plate motor 25 is connected to one end of the ball screw 26, and the mounting plate motor 25 can rotate the ball screw 26 in any direction. Arbitrary rotation of the placing plate motor 25 enables the placing plate 20 to move in an arbitrary uniaxial direction (left-right direction) along the arrows in the figure. In addition, the method of moving the placing board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com