Plastering method and apparatus for counterweight or spring traction force

A technology of traction force and equipment, which is applied in the direction of architecture and building structure, can solve the problems of unsatisfactory effect, complex structure, high cost, etc., and achieve the effect of convenient and labor-saving transportation, simple equipment structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

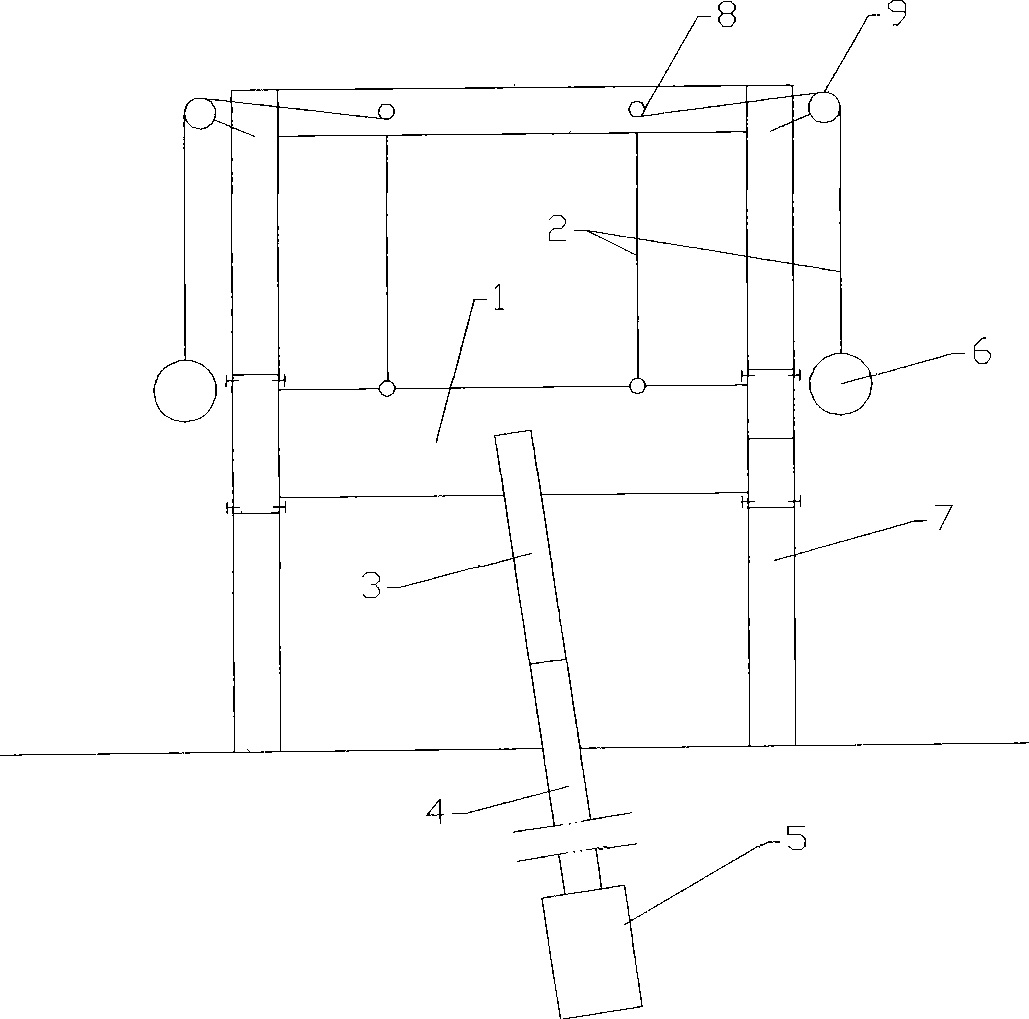

[0016] according to figure 1 , figure 2 , image 3 As shown, the plastering equipment with counterweight or spring traction includes: the main body 1 of the plastering machine is connected with the counterweight 6 or the rope 2 of the spring connected with the traction force, and the rope 2 is wound around the pulley 8 and the pole of the top beam of the support 7 On the upper pulley 9, the plastering machine main body 1 is also connected with the ash delivery device.

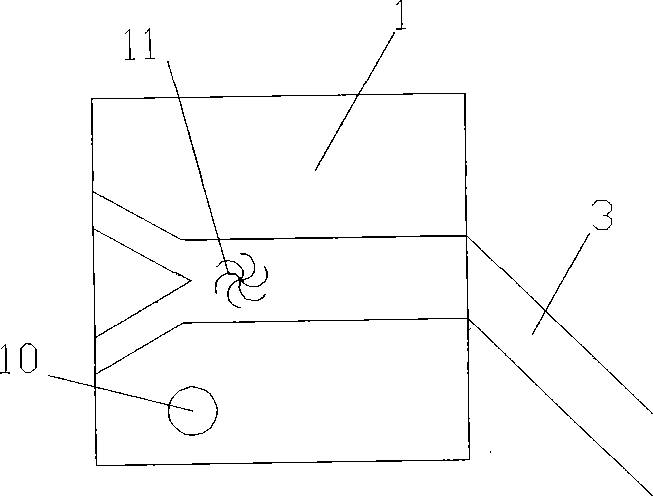

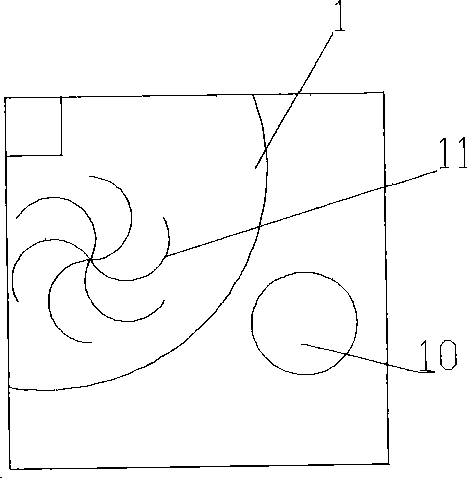

[0017] The main body 1 of the plastering machine includes: a motor 10, and an auger 11 connected to the motor 10. There are two ash outlets on the main body 1 of the plastering machine. The motor 10 and the auger 11 pass through a belt and a pulley, or a chain and a sprocket, Or gear transmission parts are connected.

[0018] The ash delivery device includes: a hand push rod 3 of a feeding pipe connected to the main body of the plastering machine 1 , the hand push rod 3 is connected to a hose 4 , and the ho...

Embodiment 2

[0021] according to figure 1 , figure 2 , image 3 As shown, the plastering equipment with counterweight or spring traction includes: the main body 1 of the plastering machine is connected with the counterweight 6 or the rope 2 of the spring connected with the traction force, and the rope 2 is wound around the pulley 8 and the pole of the top beam of the support 7 On the pulley 9 on.

[0022] The main body 1 of the plastering machine includes: a motor 10, and an auger 11 connected to the motor 10. There is only one ash outlet on the main body 1 of the plastering machine, and the ash is fed manually by the ash hopper. The motor 10 and the auger 11 pass through a belt and a pulley , or the chain and the sprocket, or the gear transmission part is connected.

Embodiment 3

[0024] according to figure 1 , figure 2 , image 3 As shown, the plastering equipment with counterweight or spring traction includes: the main body 1 of the plastering machine is connected with the counterweight 6 or the rope 2 of the spring connected with the traction force, and the rope 2 is wound around the pulley 8 and the pole of the top beam of the support 7 On the upper pulley 9, the plastering machine main body 1 is also connected with the ash delivery device.

[0025] Plastering machine main body 1, including: plastering machine main body 1 has a mortar pump extrusion type with two ash outlets, plastering machine main body 1 does not have a motor, the gear on the shaft of the auger 11 and the rack drive on the bracket engage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com