Horizontal axle windmill and method for making wind-powered unit vane

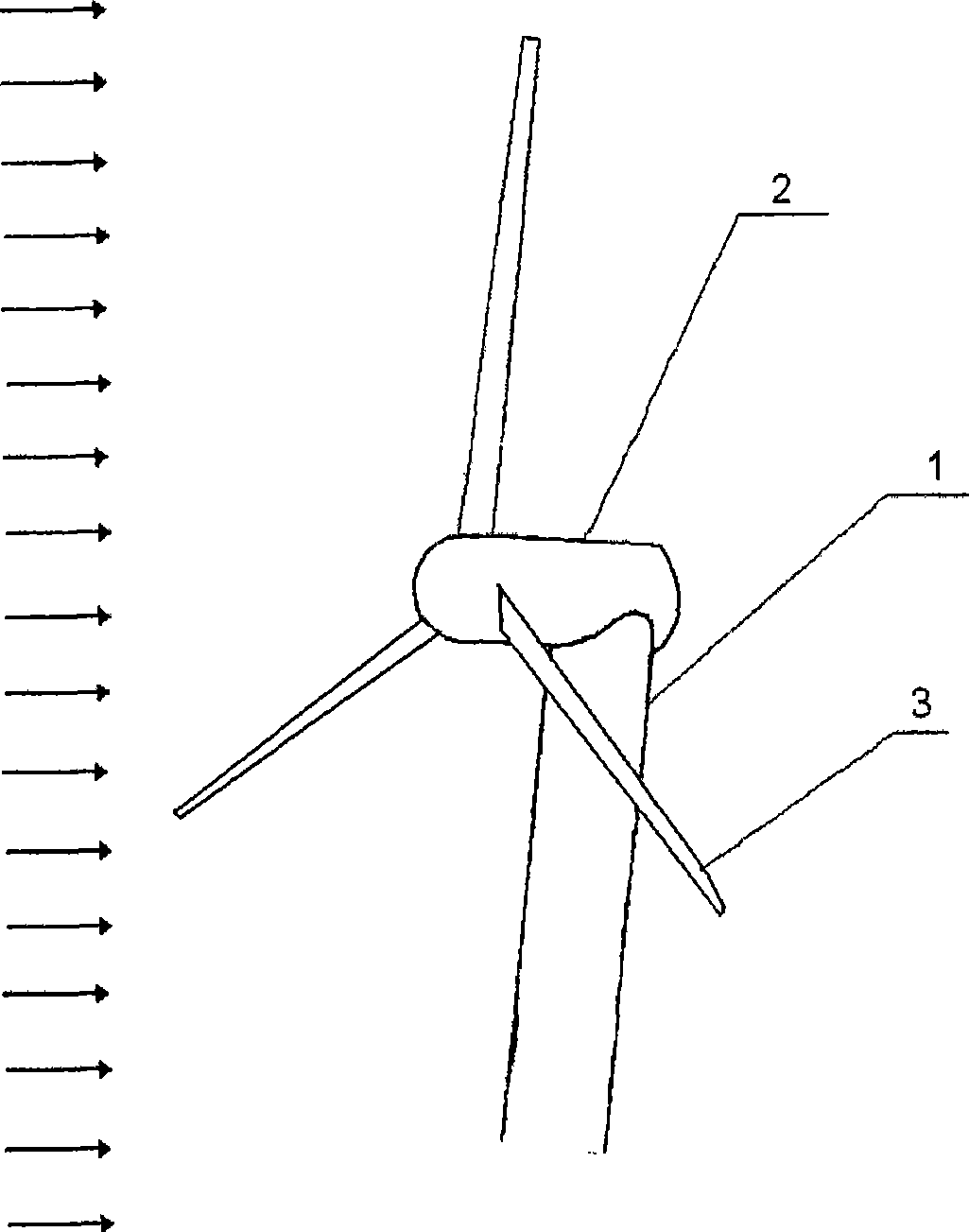

A manufacturing method and horizontal axis technology, which can be applied to wind turbines, wind energy power generation, wind turbines and other directions that are consistent with the wind direction, and can solve the problem of increasing the influence of blades, reducing the energy absorption rate of aerodynamic performance wind rotors, reducing blade safety, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

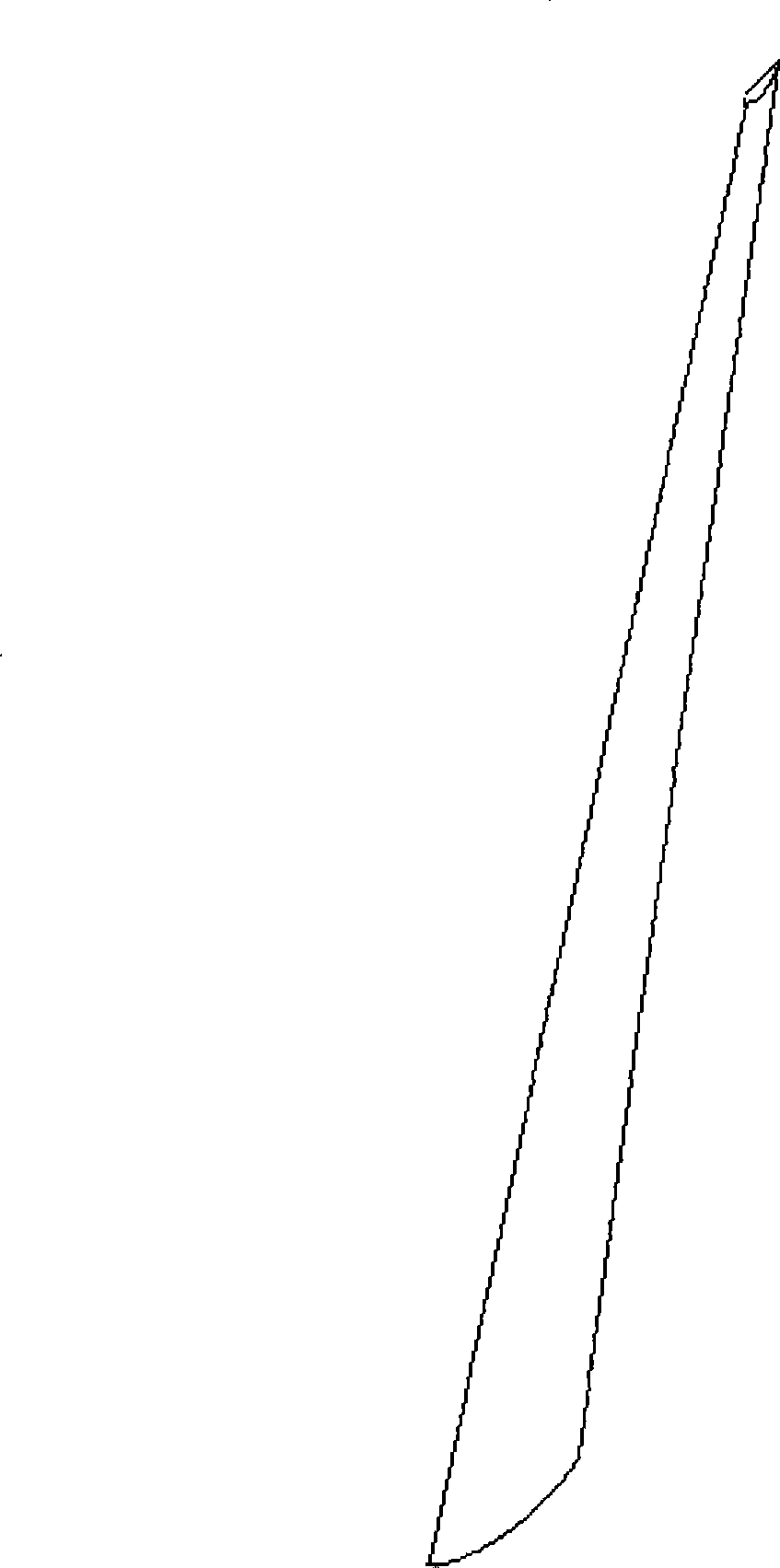

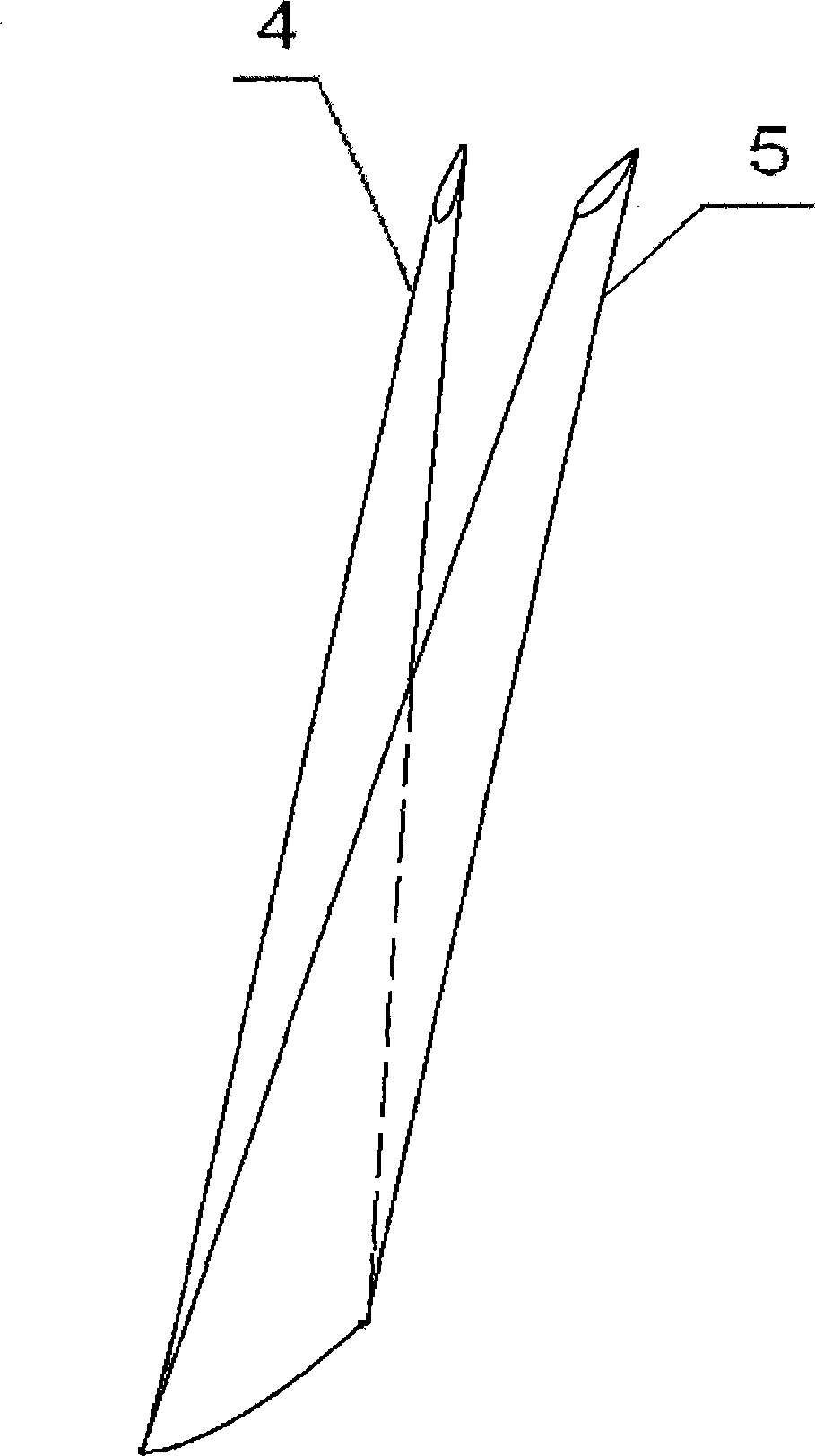

[0045] Embodiment 1: A wind turbine blade 3 is 37m long. In the design target, the shape of the root of the blade 3 is as follows: Figure 11 As shown in A in , α is the installation angle of the blade root, and the shape of the top is as follows Figure 11 As shown in B in , β is the installation angle of the top of the blade. When the wind rotor is running, the line connecting the centroids of the airfoils along the radial direction is a straight line and completely in the radial direction, as shown in Figure 12 In , the abscissa T is the circumferential direction in the cylindrical coordinate system, the ordinate h is the radial direction, 7 is the line connecting the centroids of the airfoils along the radial direction, and the installation angle of each section is at the design position. Consider the stiffness of the blade 3, the aerodynamic load, the inertial force and the influence of the prestress on the deformation, the connecting line of each airfoil center of the b...

Embodiment 2

[0046] Embodiment 2: a wind turbine blade 3, 80m long, in the design target, the difference between the root installation angle of blade 3 and the top installation angle is -45 degree, when the wind wheel is running, the connecting line of each airfoil center is a straight line and Fully radial, the mounting angle is in the design position. Considering the stiffness, aerodynamic load and inertial force of the blade 3, the line connecting the centers of each airfoil of the blade is bent forward from the root to the top, and the bending law is:

[0047] l = a ( y - y h y t - y h ) 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com