Numerical controlled new index table of horizontal machine center

A technology for indexing workbenches and machining centers, applied to metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low service life, complex structure, easy wear, etc., and achieve difficult manufacturing and simplified indexing The effect of high structure and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

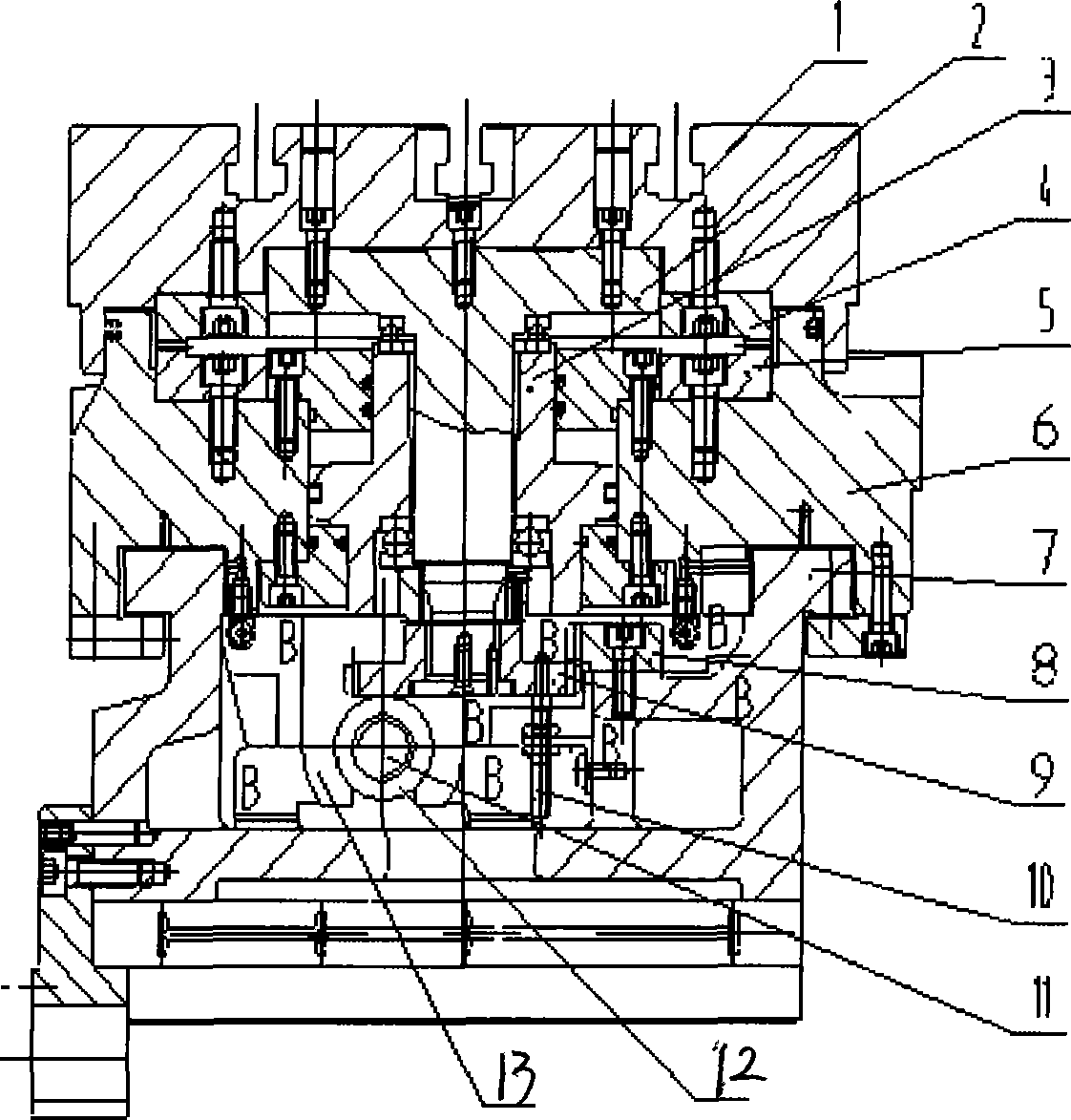

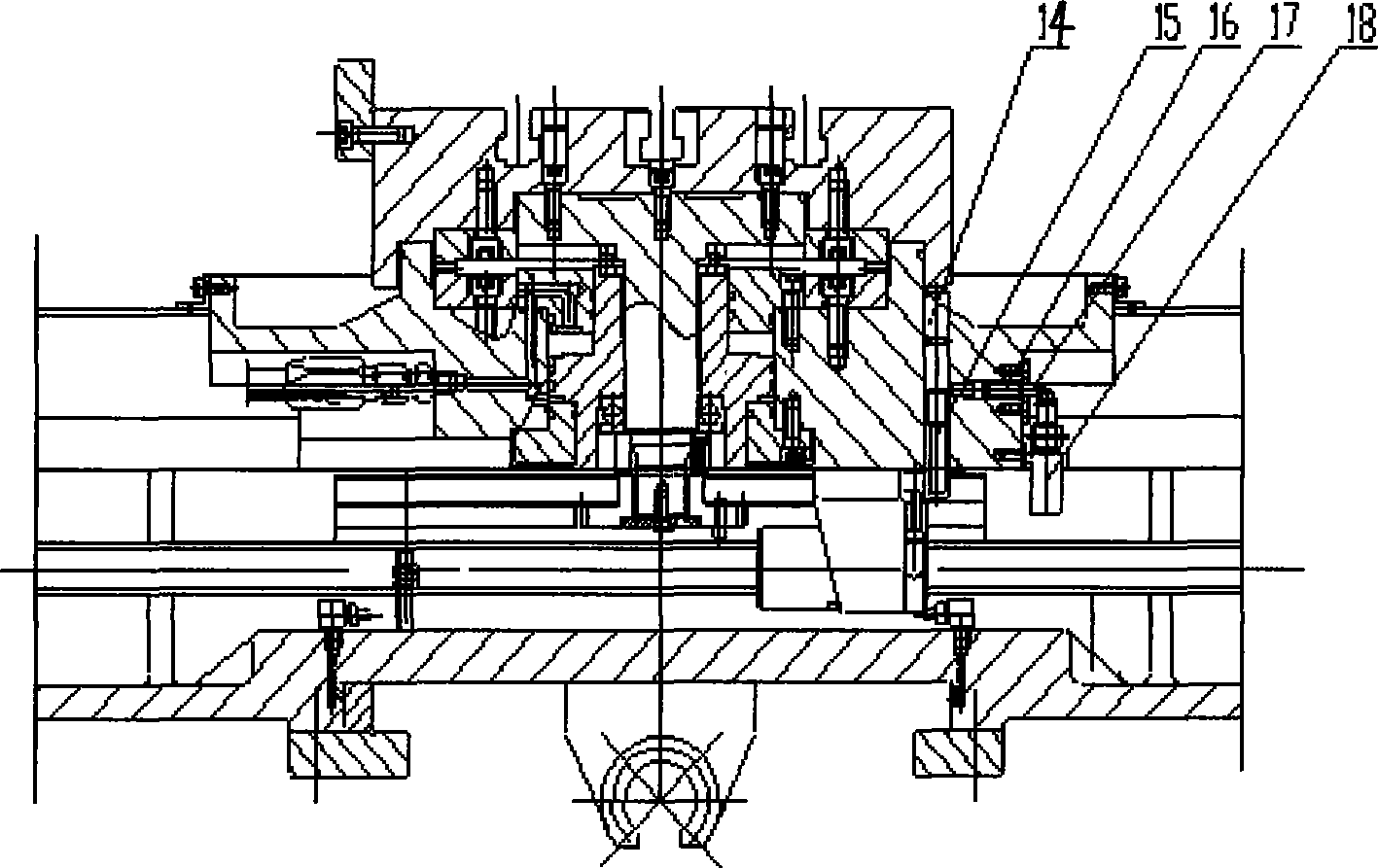

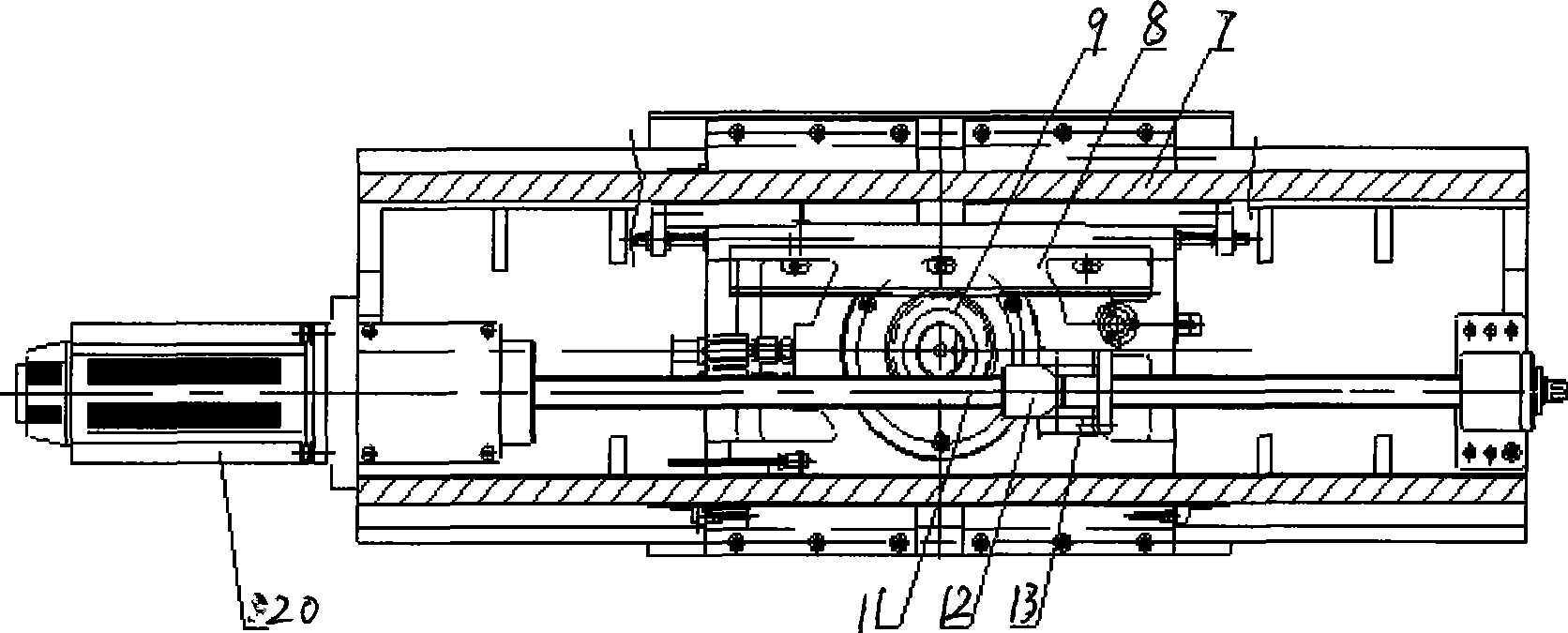

[0013] Referring to the accompanying drawings, a new numerically controlled indexing workbench for a horizontal machining center includes an upper saddle 6, a lower saddle 7 and a workbench 1. The upper saddle 6 is equipped with a lower gear plate 5, and the center of the upper saddle 6 is A piston 3 is sleeved, a support shaft 2 is sleeved in the piston 3, a worktable 1 is sleeved above the support shaft 2, and an upper toothed disc 4 is installed at a position where the worktable 1 is opposite to the lower toothed disc 5, and the sliding A nut seat 13 is installed on the saddle 7, and a screw nut 12 is arranged in the nut seat 13. The screw nut 12 is set on one end of a ball screw 11, and the other end of the ball screw 11 is driven by a motor 20. The working The bottom of the table 1 is connected with a transmission rod 14 covered with a compression spring 15, the transmission rod 14 is connected with the travel switch 18 through a switch collision rod 17, the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com