Box separation device for products package box on production line

A packing box and production line technology, which is applied in the field of box dividers, can solve problems such as jamming, high failure rate, and wear of box guide rails, and achieve the effects of avoiding damage, low failure rate, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

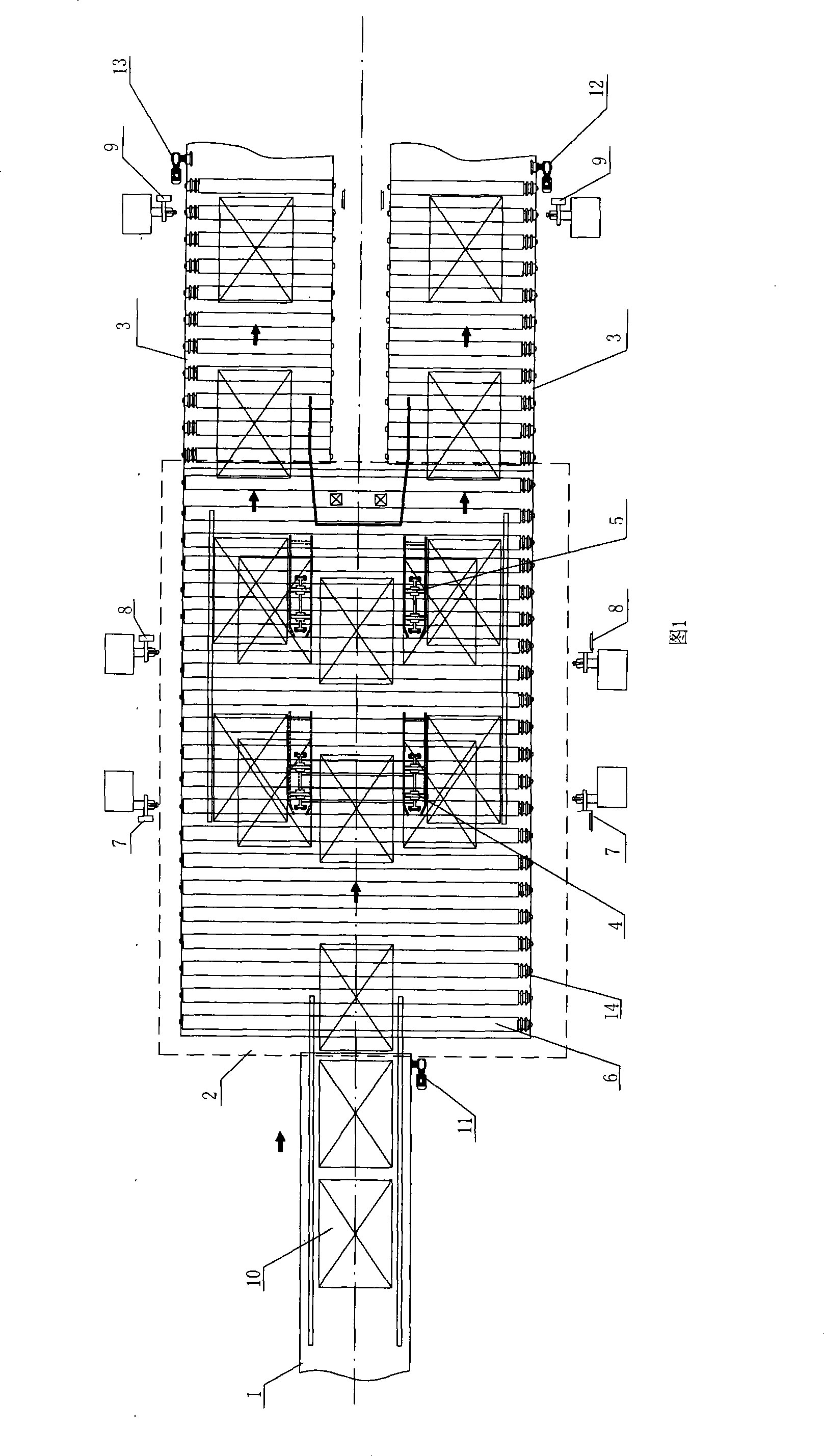

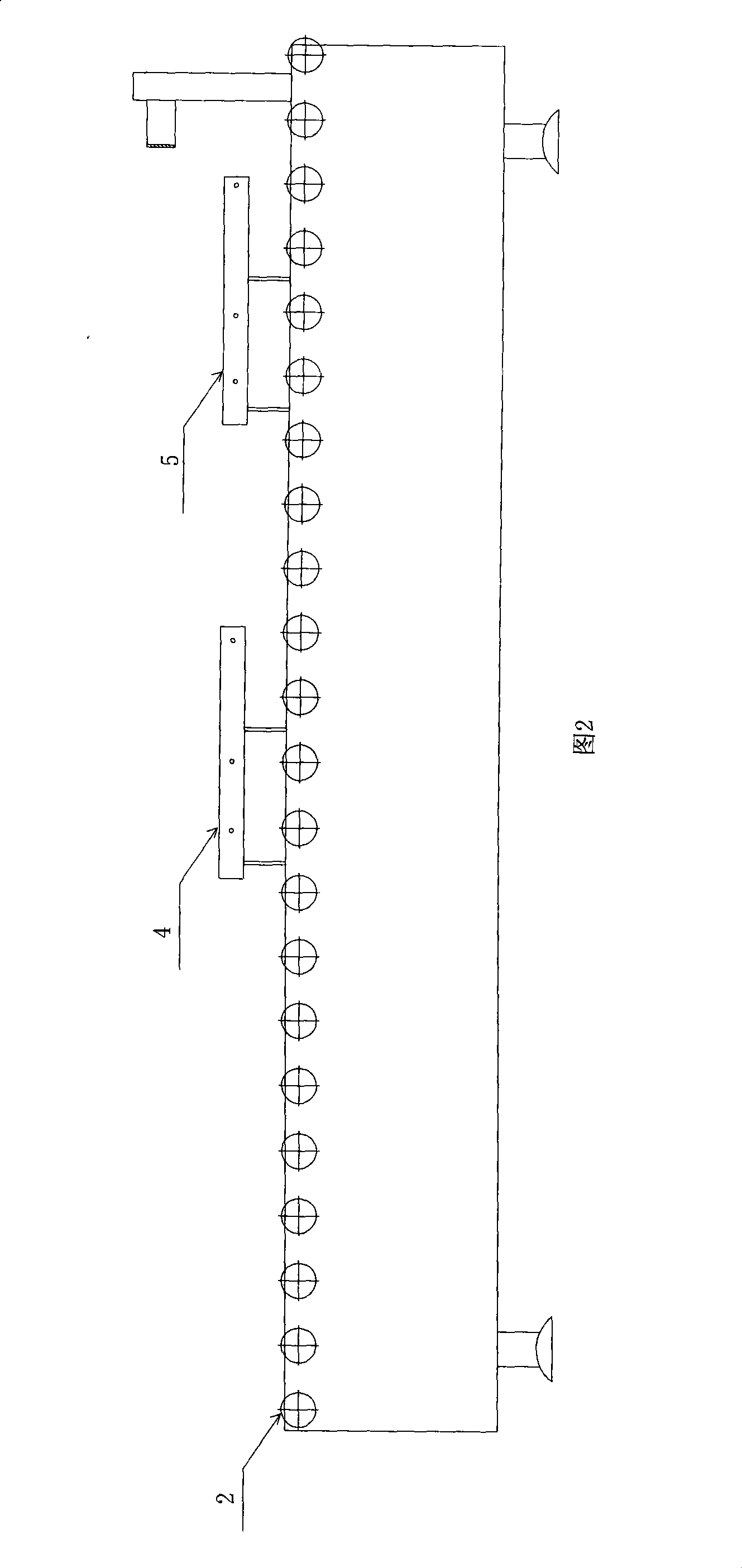

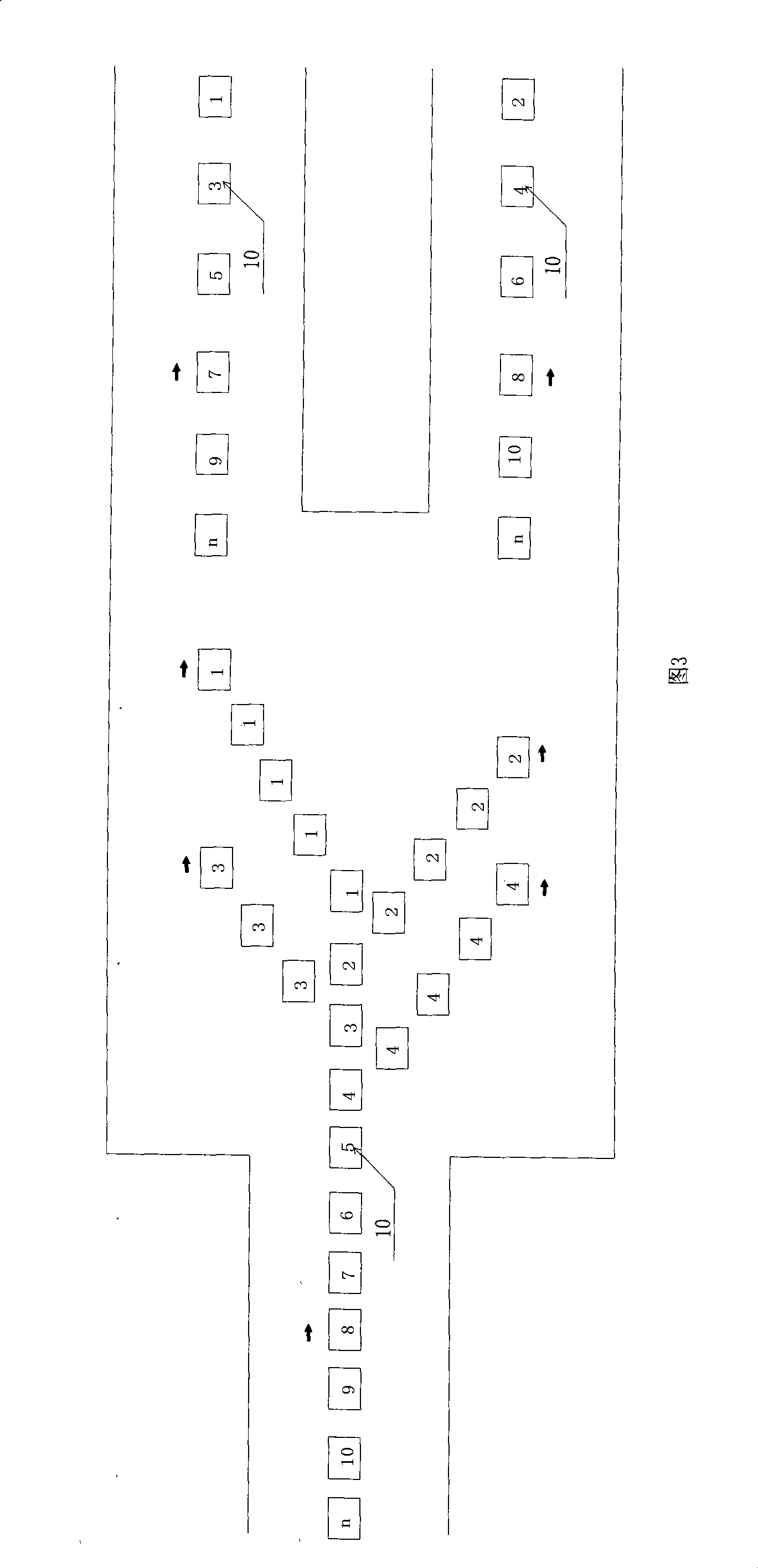

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] As shown in Fig. 1 and Fig. 2, the present invention is used for the case divider of product packing case on the production line, comprises conveyer belt 1, single row conveyer line 3 and the case dividing platform 2 between the two, and packing case 10 is separated from conveyer belt 1 is sent to the case-distributing platform 2, and after the case-dividing platform 2 is divided to the left and right sides by the case-distributing mechanism 4, 5, it is output by the single-row conveying line 3. Wherein, the conveyer belt 1 is driven by the first motor 11, the roller 6 of the box-dividing platform 2 and the right single-row conveying line is driven by the second motor 12 through the sprocket 14, and the roller 6 of the left single-row conveying line is driven by the third The motor 13 is driven by a sprocket 14 . The conveying speed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com